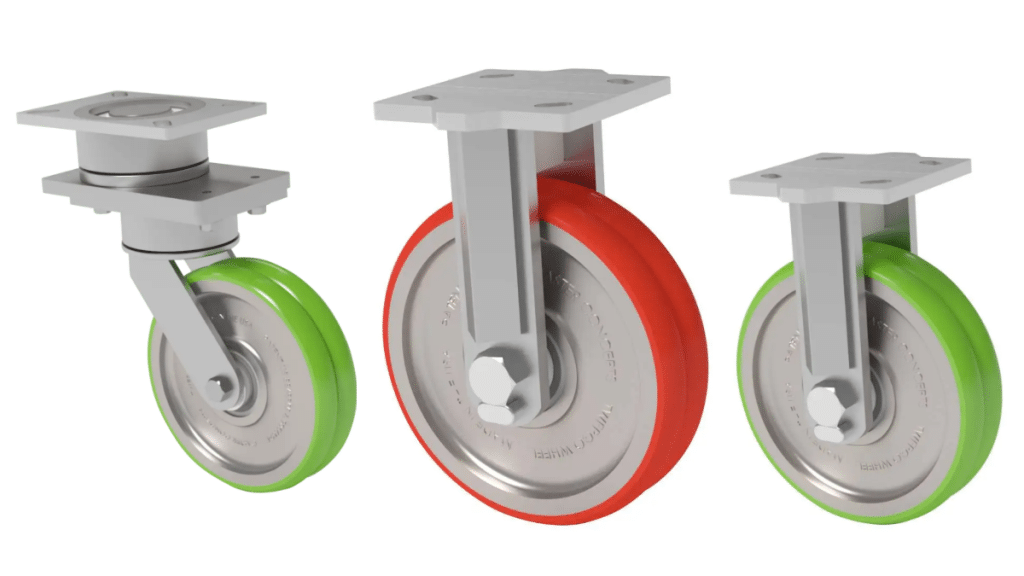

In industrial settings, the significance of heavy-duty wheel casters cannot be overstated. These robust pieces of equipment offer a perfect blend of durability and maneuverability, making them an essential component in various applications.

Unlike their medium-duty counterparts, heavy-duty wheel casters are designed to support substantial loads and withstand demanding work environments.

What Will You Learn?

This article will explore these indispensable tools’ selection, use, and maintenance. By the end of this blog, you’ll have a comprehensive understanding of choosing the right caster and wheel for your application, how to use them efficiently, and how to maintain them to ensure longevity.

Understanding Heavy Duty Wheel Casters:

Wheel casters are a significant part of various industrial applications. The heavy-duty wheel casters, typically capable of handling loads from 2000 lbs up to 5000 lbs, are marvels of engineering that facilitate the easy movement of hefty materials and equipment.

These casters are crafted via specialized manufacturing processes tailored to provide optimal performance in diverse industrial environments.

On the other hand, medium-heavy duty casters have a capacity ranging from 900 lbs to 1,999 lbs. These casters are frequently employed for hand carts and dollies, especially within the automotive and aerospace industries.

The critical distinction between these two types lies in their load capacities and intended uses. Heavy-duty casters are designed for more strenuous tasks, while medium-heavy-duty ones are suited for less demanding applications.

Selection of Heavy-Duty Wheel Casters – Making the Right Choice

● Understanding the Application Requirements:

Choosing the right heavy-duty wheel caster requires a thorough assessment of application requirements. Considerations should include the environment, such as floor conditions and temperature. Understanding load requirements and how weight is distributed across the casters is also crucial.

● Material Selection: From Nylon to Forged Steel:

Material selection plays a significant role in matching casters to load types. Options range from nylon and polyurethane to forged steel, each offering different benefits in terms of durability and weight-bearing capacity. For instance, industrial heavy-duty casters provide reliable performance even under substantial loads, thanks to their robust construction.

● Wheel Size: Diameter and Tread Width:

The size of the wheel, including its diameter and tread width, directly influences mobility and load distribution. Larger wheels generally offer better maneuverability and distribute weight evenly across the floor surface. The tread width can also impact the caster’s performance, with wider treads providing better grip and stability.

● Locking Mechanisms: Enhancing Safety and Functionality:

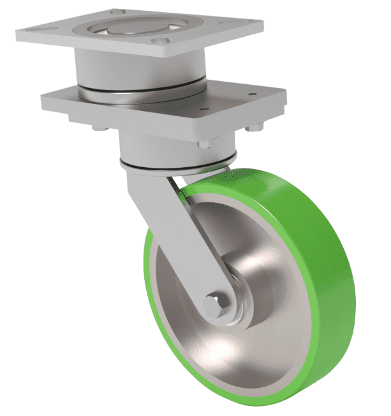

Finally, consider the locking mechanisms. Heavy-duty casters have various options, from standard caster wheel swivel locks to foot-operated mechanisms. For instance, a demountable swivel lock is an option that can be installed in the field. In contrast, the heavy-duty swivel lock offers a more extended, machined steel handle for easy operation.

Some casters even feature a passive swivel lock that provides full mobility when needed but can lock the caster for straight-line movement. Choosing the right locking mechanism enhances the safety and functionality of your heavy-duty wheel caster.

Selection of Medium-Duty Wheel Casters:

● Distinguishing Medium Duty Needs from Heavy Duty:

When choosing casters, it’s important to distinguish between medium and heavy-duty needs. Medium-duty casters are ideal for loads ranging from 900 lbs. to 1,999 lbs. These are commonly used on hand carts and dollies in industries such as automotive and aerospace.

They are a versatile solution that can address ergonomic issues like overexertion and productivity concerns like battery drain.

● Range of Wheel Types and Their Applications:

Medium-duty casters come in various types, each catering to specific applications. Brands like Twergo, Twergo Lite, and Twergo Xtreme offer ergonomic options that reduce push force and increase maneuverability.

The Swivel on Swivel design gives a dual swivel action, enhancing mobility. CasterShoX, on the other hand, is designed to mitigate shock and vibration. The type of caster chosen must align with the intended application for optimal performance.

● Wheel Hardness and Floor Suitability:

The hardness of the wheel and its suitability to the floor surface are crucial factors. Harder wheels typically roll easier and can withstand wear and tear better, but they may damage softer floor surfaces. Consideration must also be given to Hercules Casters. These feature reinforced legs, making them capable of withstanding heavy side-load impacts, thus offering improved durability and stability.

Applications of Heavy and Medium-Duty Casters:

● Installation Techniques:

A. Correct Installation for Optimal Performance

The proper installation of heavy and medium-duty casters is critical for optimal performance. The installation process should be careful and precise, ensuring the casters are securely attached and aligned. Misalignment can lead to uneven weight distribution and compromised caster functionality.

B. Safety Checks Pre-Installation

Before installation, safety checks are paramount. Inspect the equipment and the caster components to ensure they are in good condition and suitable for the intended load. Any signs of damage or wear should be addressed before proceeding with the installation.

● Operating Guidelines:

A. Best Practices for Maneuvering Heavy Loads

When maneuvering heavy loads, moving slowly and deliberately to maintain control is crucial. Push, don’t pull, the load, and ensure the path is clear of obstacles. Regularly inspect the casters for any signs of damage or wear.

B. Speed and Handling Recommendations

For safe handling, maintain a moderate speed when moving loads. Rapid acceleration or deceleration can put undue stress on the casters and cause instability. Always adhere to the manufacturer’s speed and handling recommendations to ensure longevity and safety.

Tips to Maintain Wheel Casters:

● Regular Inspection Schedules:

Preventive maintenance is crucial for caster longevity. Regularly inspect the wheels for cracks, flat spots, or embedded debris. Check the bearings for smooth operation and the mounting plate for secure attachment.

Keeping records of maintenance activities can help track the health of your casters. Note the date of inspections, any maintenance performed, and observations about wear and tear.

● Cleaning and Lubrication:

Cleaning practices vary based on caster type. Typically, use a damp cloth to wipe off dirt and debris. Avoid harsh chemicals that could damage the wheel material.

Regular lubrication ensures smooth operation. Use the manufacturer-recommended lubricant and adhere to the suggested frequency guidelines.

● Wear and Tear Monitoring:

Signs of wear include difficulty in rolling, squeaky sounds, visible cracks, or loose components. Early identification can prevent damage and improve the caster’s lifespan.

Some issues, like tightening loose components or lubricating bearings, can be repaired. However, replacement is likely the best option if the wheel is cracked or the caster frame is bent. Always consult with a professional when in doubt.

Specialized Casters and Custom Solutions:

● Ergonomic and Noise-Reduction Casters:

Ergonomic casters are designed to minimize friction with the ground, reducing the force needed to move and turn a cart or dolly. This results in less risk of injury, lower associated costs, and improved productivity.

Design features such as tapered treads, independently rotating wheels, and high-profile wheels enhance carrying capacity and reduce push force.

For noise-sensitive environments, specific design considerations can help. For example, swivel-on swivel designs offer longer leads than conventional casters, reducing the force needed to rotate the caster and start rolling while minimizing side-to-side shifting.

● Customized Caster Solutions:

Custom casters are manufactured to meet specific design requirements. They can be tailored to unique challenges, ranging from complete custom designs to simple modifications like changing the mounting pattern, overall height, swivel lead, bearings, or adding a brake or toe guard.

Caster Concepts can design a fully custom caster from scratch for unique applications. This is particularly useful when retrofitting casters into a legacy operation or handling complex loads in aerospace-related industries.

The aim is to solve specific requirements such as high speeds, noise reduction, shock absorption, ergonomic issues, durability/life cycles, and unique material handling challenges.

Caster Concepts: Leading Manufacturer of Heavy Duty Wheel Casters

Caster Concepts is a renowned industry leader in the manufacturing of heavy-duty wheel casters. With a steadfast commitment to quality, we deliver robust and reliable solutions for various industrial needs.

Our caster range includes standard offerings and custom-made casters tailored to specific requirements. The company’s expertise lies in understanding unique challenges and providing practical solutions.

Trust Caster Concepts for your heavy-duty caster needs, and experience our commitment to excellence firsthand.