Hospital steam autoclaves – also known as sterilizer machines – have had a great surge in their popularity in the past years. There are many reasons why more and more medical facilities, including dental and veterinary clinics, choose to install an on-site autoclave. Read on to find out more about their advantages!

Hospital steam autoclaves – How do these sterilizer machines work?

As their name indicates, hospital steam autoclaves make use of high-pressure, high-temperature steam to kill all manners of bacteria present on either medical waste or equipment. The temperature of the steam inside the chamber of these sterilizer machines can reach temperatures ranging between 121 and 134 degrees Celsius – more than enough to kill even heat-resistant bacteria.

The advantage of this technology is that any autoclavable material will come out completely sterile from these steam sterilizer machines. Medical waste can be thrown away like regular municipal garbage, and medical tools can be reused again for the treatment of patients without any risk of infection.

The following materials can be treated with hospital steam autoclaves:

- Media Solutions

- Biological tissue culture flasks and plates

- Paper (if placed inside an autoclave waste bag)

- Stainless steel

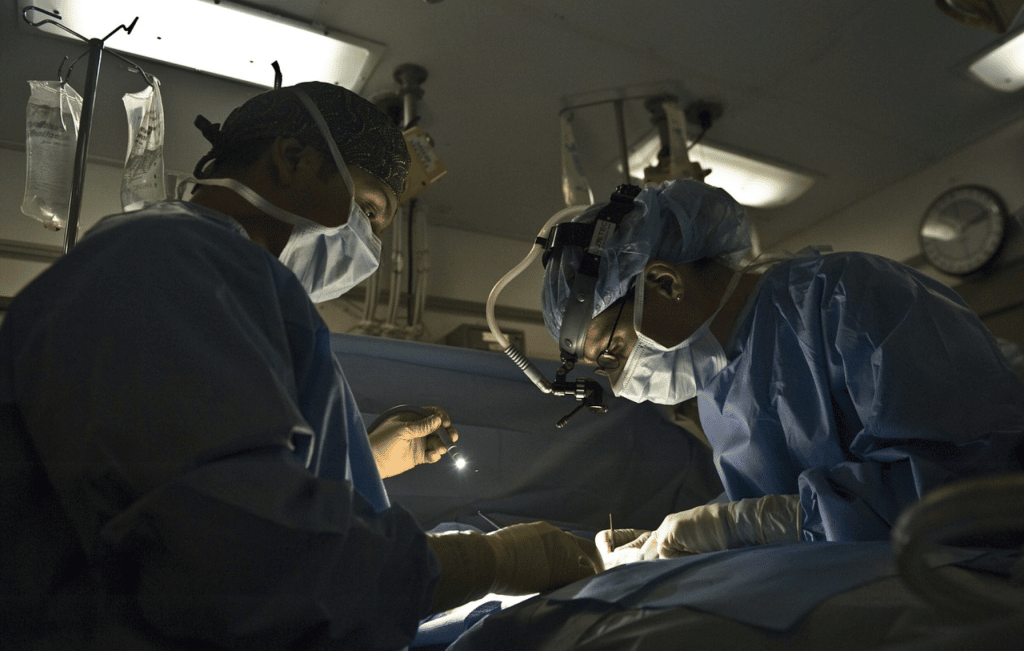

- Metallic medical tools, surgical Instruments

- Solid items contaminated by blood

- Glassware

- Latex gloves, vinyl (if placed inside an autoclave waste bag)

- Hospital linens, textile materials

- Plastic pipette tips (inside appropriate biohazard beds)

- Polypropylene and polycarbonate plastics

The advantages of hospital steam autoclaves – Sterilizer machines compared to incinerators

Compared to incineration – one of the most popular methods used by medical facilities to dispose of waste – hospital steam autoclaves have many advantages.

- Sterilizer machines are considered to be one of the best green solutions to dispose of hospital waste and are in line with the international environmental standards provided by the EU and the WHO. There is no risk of air pollution, and they emit no bad odors.

- The capital and operational costs of hospital steam autoclaves are also much lower compared to on-site incinerators, making them a much more cost-effective, and realistic option in developing countries as well.

- Sterilizer machines take also much less time to be installed at the site of hospitals before they are ready to be used by medical staff. This is further helped by the fact that they also require much less available space.

- Hospital steam autoclaves are also much more “user-friendly”, especially the more advanced vacuum (or class B) sterilizer machines. They require no extensive training to be efficiently used by staff.

What is the “best” hospital steam autoclave? The advantages of class B sterilizer machines

Autoclave manufacturers provide facilities with machines of different sizes and different categories. For example, Celitron’s hospital steam autoclaves fall within the highest category of sterilizer machines, which come with many advantages.

Class B autoclaves that use a vacuum pump are much faster at completing one full sterilization cycle, and can sterilize more types of loads – this versatility is especially important for hospitals. Larger medical facilities also need to take care in choosing a model with a big enough chamber capacity. Apart from larger vacuum autoclaves, more compact, medium-sized models are also available to be used at the site of operating theaters.