In the last few decades, industries across the globe have experienced a profound shift in how they operate. With the rise of smart technologies and automation, traditional manual processes are steadily being replaced by advanced systems that not only boost productivity but also minimize errors and downtime. Automation isn’t just a trend—it’s becoming the backbone of modern industry.

From manufacturing floors to processing plants, automation is redefining how industrial equipment functions. It’s not only about doing things faster but doing them smarter and more efficiently. So how exactly is automation shaping the future of industrial operations? Let’s explore.

Smarter Machines, Smarter Decisions

At the heart of industrial automation is the idea of giving machines the ability to make decisions. This is accomplished through sensors, control systems, and software that can analyze real-time data and respond accordingly.

Take, for example, automated assembly lines in automotive factories. These systems can detect product anomalies, adjust machine speeds, and even reorder materials—all without human intervention. The ability to process data on the fly means that machines can now optimize themselves based on current conditions.

This results in faster production times, fewer defects, and less waste—key benefits in an increasingly competitive global market.

Remote Monitoring and Predictive Maintenance

One of the biggest advantages automation brings to the table is the ability to monitor equipment remotely. Engineers and technicians no longer have to be on-site to check a machine’s health. With IoT (Internet of Things) integration, sensors feed data to centralized dashboards that can be accessed from virtually anywhere.

More impressively, this constant flow of data allows for predictive maintenance. Instead of fixing a machine when it breaks down, companies can now anticipate failures before they happen. This not only extends the life of equipment but also drastically reduces unexpected downtime, which can be incredibly costly in an industrial setting.

Energy Efficiency and Sustainability

Automation is also playing a significant role in making industries more energy-efficient. Traditional machines often operate at fixed outputs regardless of demand. Modern automated systems, however, can adjust power usage based on real-time requirements.

This doesn’t just lower energy bills—it also contributes to sustainability goals by reducing overall consumption. Companies that integrate smart energy management systems are finding it easier to comply with environmental regulations and improve their green credentials.

Furthermore, advanced automation can track metrics like heat output, voltage fluctuations, and idle times to help identify inefficiencies that may not be obvious to the human eye.

Integration with Robotics and AI

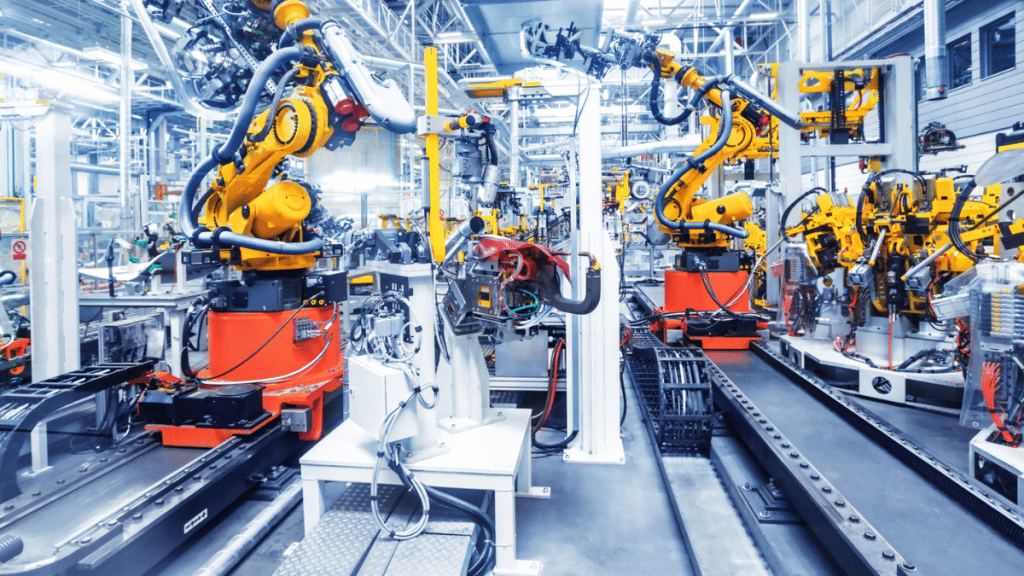

Robotics is one of the most visible aspects of automation in industrial environments. Robotic arms, autonomous vehicles, and machine vision systems are increasingly common, particularly in sectors such as electronics, pharmaceuticals, and automotive manufacturing.

But it’s not just about mechanical automation anymore. Artificial intelligence is now being integrated with industrial robots to enable more complex decision-making. AI allows machines to adapt to different situations, handle variability in products, and even learn from past tasks to improve future performance.

This hybrid approach—where robotics meets AI—is what’s setting the stage for the factories of tomorrow. And the changes are already visible today.

Streamlining Operations Across the Board

Automation is not limited to machinery on the factory floor. It’s now touching every part of industrial operations—from inventory management to logistics to customer service.

Warehouse automation, for instance, can sort and transport products with remarkable speed and accuracy. Software systems can analyze inventory levels and automatically place orders for raw materials. Even administrative tasks such as scheduling and reporting can be automated to save time and reduce human error.

The result? A seamless, integrated operation where every part of the workflow communicates with the rest of the system.

Core Components Driving Automation

While there are many technologies enabling this shift, certain components are central to the process. One such component is the electric motor driver. These devices are critical in controlling the speed, direction, and torque of electric motors, which are used in everything from conveyor belts to robotic arms. Without reliable drivers, the level of precision and control required for modern automation simply wouldn’t be possible.

In recent years, motor drivers have become more compact, efficient, and intelligent, supporting the wider push toward smart manufacturing. Many now come with built-in diagnostics, communication interfaces, and compatibility with various control systems, allowing for seamless integration into automated setups.

Challenges and Considerations

While automation brings undeniable advantages, it’s not without its challenges. Implementing automated systems requires significant upfront investment, and not all legacy equipment is compatible with new technologies.

There’s also the issue of workforce adaptation. As machines take over routine tasks, human roles are evolving toward more strategic and analytical functions. Companies must invest in upskilling their staff to keep pace with technological changes.

Cybersecurity is another key concern. With so much data being transmitted and machines being controlled remotely, protecting these systems from threats becomes crucial.

The Road Ahead

The future of industrial equipment is undoubtedly automated. With advancements in AI, IoT, and machine learning, the capabilities of automated systems will only grow stronger. Equipment will become even more autonomous, more interconnected, and more intelligent.

For companies willing to embrace this evolution, the rewards are significant: higher efficiency, reduced costs, better safety, and the flexibility to adapt quickly to market demands.

Automation is not just transforming how equipment operates—it’s transforming how industries think, plan, and grow. As the technology matures, the divide between the digital and physical worlds in manufacturing will continue to blur, paving the way for truly smart factories.