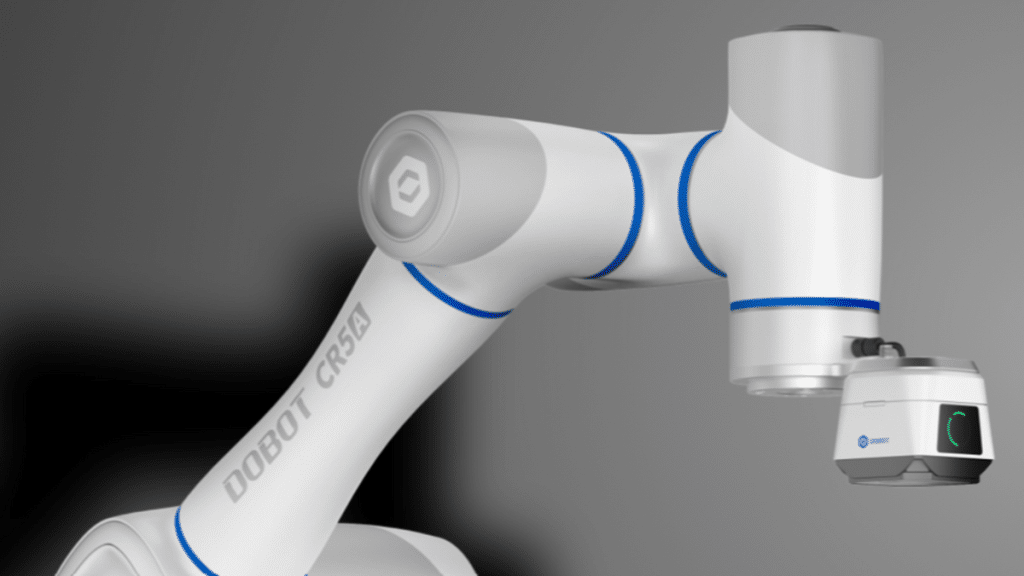

Integrating robotics into various industries has revolutionized tasks, offering unparalleled efficiency and precision. Collaborative robotics, or cobots, has emerged as a game-changer among these advancements. Designed to work alongside humans, cobots transform industries by automating repetitive tasks, enhancing safety, and boosting productivity. One notable example is the DOBOT cobot, which has gained recognition for its versatility and user-friendly design.

The Rise of Collaborative Robots in Modern Workspaces

Collaborative robots are no longer confined to large-scale industrial settings. Their compact design, ease of use, and adaptability make them suitable for businesses of all sizes. Unlike traditional robots, cobots are designed to work near humans, ensuring safety without extensive protective barriers. This unique feature has made them indispensable in the manufacturing and healthcare industries.

Key Features of Collaborative Robots

Cobots are equipped with advanced sensors and programming capabilities to perform complex tasks precisely. Their ability to adapt to various applications makes them valuable assets in dynamic work environments. For instance, the DOBOT cobot is known for its six-axis movement, enabling it to easily handle assembly, packaging, and quality inspection tasks.

Technical Capabilities That Set Cobots Apart

The technical specifications of cobots largely decide what jobs they can tackle. For instance, Dobot’s CR 16 handles up to 16 kg with a certified repeatability of ±0.03 mm, fitting many precision pick-and-place or screw-driving tasks in electronics and semiconductor lines. When payload needs rise to 20 kg, the CR 20A meets that load with ±0.05 mm repeatability, which is typical among heavy-duty cobots from other makers.

Safety and Human-Robot Collaboration

Safety is a top priority in the design of cobots. Advanced technologies like non-contact collision detection and integrated safety functions ensure seamless human-robot interaction. These features minimize the risk of accidents and enhance productivity by allowing humans and robots to work together efficiently.

Applications of Cobots Across Industries

The versatility of cobots has led to their adoption in a wide range of industries. Here are some notable applications:

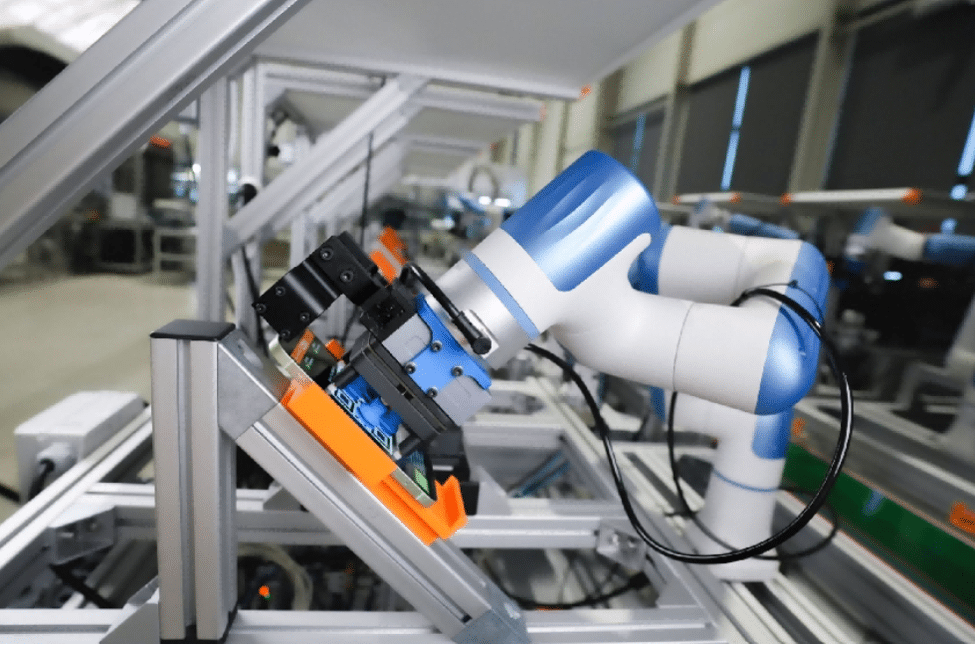

1. Electronics Assembly

The electronics industry thrives on precision and rapid production. Cobots are indispensable in tasks like PCB assembly, where their ability to handle fragile components with a repeatability of 0.02 mm ensures exceptional accuracy. By automating these intricate processes, businesses achieve faster turnaround times, reduce operational errors, and maintain consistent quality, ultimately enhancing productivity and meeting the market’s growing demands.

2. Metal Processing and Welding

Cobots are revolutionizing metal processing and welding by automating traditionally labor-intensive tasks. Equipped with visual deployment software and integrated mobility, they efficiently map workstations, streamline material handling, and execute precise operations. This automation alleviates physical strain on workers and enhances productivity, reducing production cycles by up to 30% while ensuring consistent quality and operational efficiency.

3. Semiconductor Manufacturing

The semiconductor industry relies heavily on precision and consistency, making cobots indispensable. These advanced robots excel in wafer handling, defect detection, and process control, ensuring accuracy and uniformity. Cobots significantly enhance production quality and output by yielding up to 90%. Their efficiency is vital for staying competitive in this fast-paced, innovation-driven sector, where precision defines success.

4. Food and Beverage Packaging

Cobots are revolutionizing the food and beverage industry by automating labor-intensive packaging processes. Their precision and efficiency enable companies to meet high production demands without compromising quality. By streamlining operations, cobots reduce manual errors and improve consistency. Businesses integrating cobots into their production lines have reported up to a 50% boost in efficiency, ensuring faster delivery and enhanced customer satisfaction.

Compact Solutions for Small and Medium Enterprises

The adoption of robotics is no longer limited to large corporations. Compact cobots, such as SCARA and desktop units, are designed to meet the needs of small and medium-sized enterprises (SMEs). These models offer a cost-effective way to automate processes without requiring extensive modifications to existing workflows.

SCARA and Desktop Cobots

SCARA cobots are known for their high precision and versatility, making them suitable for material handling and assembly tasks. On the other hand, desktop units are useful in dispensing, labeling, and light pick and place applications in industrial fields., offering a compact design that seamlessly fits into limited workspaces.

The Future of Collaborative Robotics

As technology evolves, cobots’ capabilities are expected to expand further. Innovations in artificial intelligence and machine learning will enable cobots to perform even more complex tasks, making them an integral part of the workforce. Brands like DOBOT are at the forefront of this revolution, offering solutions catering to various applications.

Conclusion

Collaborative robots have progressed from niche industrial tools to versatile partners that amplify human capability across sectors. By blending compact, sensor-rich designs with intuitive programming, cobots like DOBOT deliver precision, safety, and cost-effective scalability for enterprises large and small. Their impact—accelerated cycles, higher yields, and minimized ergonomic risk—demonstrates how automation can humanize work rather than replace it. As AI and machine learning deepen cobot intelligence, businesses embracing this synergy today will shape tomorrow’s resilient factories and labs.