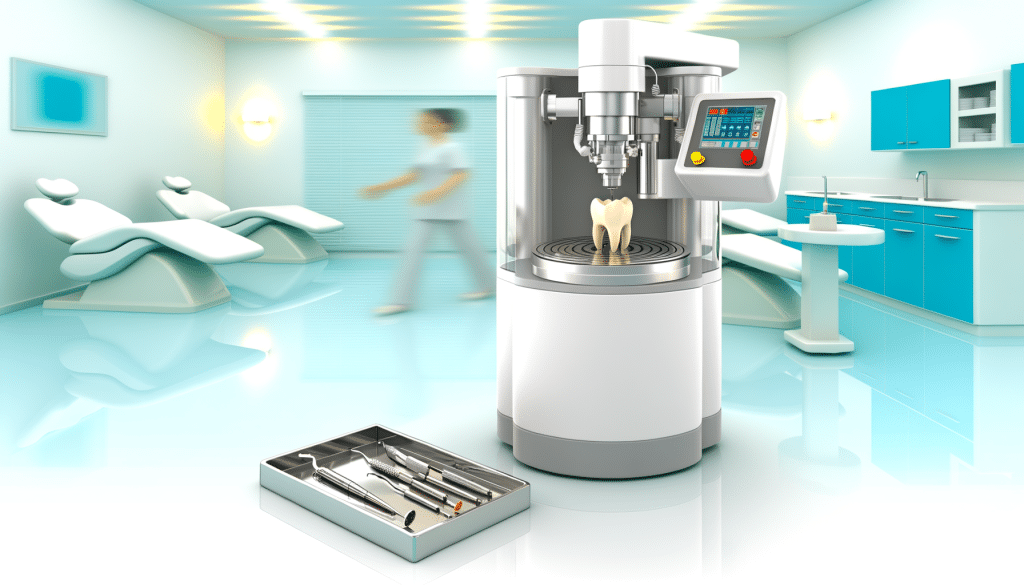

In modern dentistry, the drive toward precision, efficiency, and patient comfort has led to rapid technological innovations. One of the most significant breakthroughs in restorative dental care is the adoption of dental milling machines. These devices have revolutionized the process of crafting dental restorations, allowing clinics to move away from time-consuming, error-prone traditional methods.

Instead of relying on external dental labs and manual modeling, dentists can now design and fabricate crowns, bridges, veneers, and more right in their own offices. This shift brings not only faster turnaround times but also vastly improved restoration accuracy, a critical factor in long-term oral health and patient satisfaction. So how exactly do these machines enhance precision, and what makes them such a transformative addition to the dental workspace?

Precision Begins at the Design Stage

Digital planning plays a major role in ensuring restorative accuracy.

Dental milling machines work as part of a broader digital workflow, usually beginning with intraoral scanning. This step captures a patient’s dentition in high detail, avoiding the distortions common with traditional impressions. The resulting digital file becomes the blueprint for the final restoration. When transferred to the design software, every detail can be measured and refined with mathematical precision. This digital approach ensures that what gets milled is a faithful reproduction of the patient’s unique oral structure.

Consistency Through Automation

Automation reduces human error and creates predictable, high-quality outcomes.

Traditional restorative techniques often depend on the skill and experience of individual lab technicians. While many are exceptionally talented, the process is inherently variable. With dental milling machines, the restoration is produced exactly as designed, every time.

Once the specifications are finalized, the machine executes the task with micrometer-level precision, creating consistency that’s almost impossible to match manually. This automation greatly reduces the margin of error and ensures restorations fit properly from the start.

Materials Matter: Uniformity and Biocompatibility

The use of milled materials leads to stronger, more accurate restorations.

Another key factor in the improved accuracy of restorations is the quality and consistency of the materials used. Blocks or discs of zirconia, lithium disilicate, and other ceramics are manufactured under controlled conditions, ensuring they have uniform density and strength. Because dental milling machines carve from these pre-processed blocks, the final restoration benefits from these uniform properties. The result is a precise fit that doesn’t weaken over time due to material inconsistencies.

Enhancing Fit and Contact Accuracy

Tight margins and correct contact points are critical to long-term success.

One of the biggest reasons restorations fail is poor marginal integrity. If a crown or veneer doesn’t fit snugly around the tooth, bacteria can enter, leading to decay or gum irritation. Dental milling machines produce restorations with precise margins that minimize gaps and reduce the likelihood of complications. Similarly, correct contact points with neighboring teeth ensure comfort during chewing and prevent food from getting trapped, another common problem with less accurate methods.

Chairside Milling Enables Same-Day Restorations

Fewer visits and faster results don’t mean sacrificing quality.

Dental practices equipped with milling machines can offer same-day restorative procedures. After scanning and designing the restoration digitally, it can be milled, finished, and placed in just a few hours. This not only improves patient convenience but also increases accuracy.

The shorter time frame between tooth preparation and final placement minimizes the risk of movement or changes in the tooth’s structure, which can affect how well a traditional lab-fabricated crown fits days later.

Real-Time Validation with Intraoral Scanners

Live visual feedback improves accuracy before milling even begins.

Intraoral scanners provide dentists with real-time 3D images of the patient’s mouth, allowing them to identify and correct imperfections before the milling process begins. Whether it’s a missed margin or a misaligned bite, the ability to correct issues instantly ensures that only high-quality data is used for fabrication. This proactive step significantly contributes to the overall accuracy and reduces the need for reworks or adjustments.

Multi-Axis Capabilities Create Complex, Natural Shapes

More movement allows for more lifelike and precise restorations.

Many dental milling machines today are equipped with 4-axis or 5-axis capabilities. This allows the tool to move in multiple directions during the milling process, enabling it to reproduce complex anatomical structures such as deep grooves and undercuts.

These finer details contribute not just to aesthetics but also to functional performance. When a restoration mirrors the natural structure of a tooth, it integrates more seamlessly with the surrounding dentition.

The Role of Dental Milling Machines in a Modern Practice

Seamlessly integrated technology drives both efficiency and accuracy.

The growing presence of Dental Milling Machines in clinics is no longer just a trend, it’s becoming a standard. These systems offer a balance of precision, speed, and control that traditional methods cannot match. Whether used for routine crown placement or more advanced prosthodontics, their contribution to accurate outcomes is undeniable. Their ability to mill exact replicas of digital designs eliminates layers of guesswork that often arise when work is outsourced to labs.

Reduced Rework and Long-Term Savings

Accurate from the start means fewer problems down the line.

Mistakes in restorative dentistry can be expensive, not just financially, but also in terms of patient trust and clinical time. Poor fits lead to adjustments, re-impressions, or even total remakes. With milling machines, the restoration is fabricated to such tight specifications that these problems become far less common. Over time, this accuracy results in fewer failures, longer-lasting work, and reduced costs for both patient and provider.

Final Thoughts: Accuracy Redefined

Technology is not just speeding up dentistry, it’s refining it.

In the past, high accuracy in dental restorations often meant long turnaround times, multiple visits, and heavy reliance on skilled technicians. Dental milling machines have changed that narrative. By integrating digital scanning, advanced design tools, and computer-controlled milling, they provide a level of precision that is faster, more consistent, and more reliable than traditional methods. As dentistry continues to embrace these innovations, the standard of care improves, not just for the dentist, but most importantly, for the patient.