A brand-new HVAC system should deliver steady comfort, predictable energy use, and quiet operation, yet “new” does not always mean “perfect.” Performance gaps can appear immediately after installation because a system is only as good as its setup, airflow balance, control configuration, and the building conditions it’s installed in. Homeowners might notice uneven temperatures, short cycling, humidity that feels off, or higher-than-expected bills, and assume the equipment is defective. In many cases, the root cause is simpler: mismatched capacity, improper duct performance, sensor placement issues, or commissioning steps that were rushed. Contractors identify these gaps by separating symptoms from causes and validating how the system behaves under real operating conditions. They look for clues in run times, temperature changes, static pressure readings, and control logic, then confirm findings with measurements rather than guesswork. Early checks protect comfort, reduce wear, and help the equipment perform as intended from day one.

A practical guide to diagnosing early issues

Confirming design intent versus real-world conditions

The first step in finding a performance gap is comparing what the system was intended to do with what the home or building actually demands. Contractors review the match between equipment capacity and the load it must handle, because even new equipment can struggle if sizing assumptions were off or if the building changed after design. Added insulation, new windows, renovations, or a finished attic can shift airflow needs and heat gain patterns. They also verify that the selected system type aligns with the application—single-stage, two-stage, variable-speed, heat pump, or furnace/AC combination—because control strategy influences comfort and efficiency. Return and supply placement matters, too: a powerful system cannot correct weak circulation caused by poor grille locations or blocked returns. Contractors compare expected temperature split, airflow per ton, and target humidity control with what the system is delivering at the registers. One sentence captures the practical reality: an air conditioning contractor often finds that performance complaints in new installations trace back to airflow and setup details, not the unit itself. This “intent versus reality” check frames every next test.

Reading the system’s “behavior” through run patterns

Before instruments are released, contractors monitor how the system behaves over time. Short cycling—frequent starts and stops—can indicate oversizing, incorrect thermostat setup, poor airflow, or a refrigerant or sensor issue. Long run times with weak temperature change may signal low airflow, duct leakage, incorrect refrigerant charge, or coil performance restrictions. They ask when discomfort happens: mornings, afternoons, or only during cooking or showers. Timing reveals whether solar load, ventilation, occupancy, or moisture generation is pushing the system beyond the controls’ ability to manage. Noise is also diagnostic. Whistling at a return can hint at excessive static pressure or undersized returns. A “whoosh” at startup may indicate dampers slamming or a pressure imbalance. Contractors also look for condensation patterns, including sweating ductwork or water where it shouldn’t be, because moisture problems can indicate airflow and temperature mismatch at the coil. By mapping symptoms to patterns, they narrow the likely causes and avoid random adjustments that make the problem harder to trace.

Airflow verification and duct performance testing

Airflow is the backbone of HVAC performance, and many “new system” complaints begin with ducts. Contractors measure external static pressure and compare it with manufacturer limits to determine whether the blower is operating against excessive resistance. High static pressure can come from restrictive filters, undersized returns, tight duct bends, crushed flex duct, dirty coils, or even on new installs due to construction dust or closed dampers. They confirm blower settings and ensure the correct fan profile is chosen for the equipment and accessories, such as media filters or humidifiers. Next, they evaluate delivered airflow at the registers and overall system airflow, as low airflow reduces capacity, increases energy use, and can cause coil icing or poor dehumidification. Duct leakage checks help explain why a new unit can feel weak—conditioned air may be escaping into attics or crawlspaces while rooms starve for supply. They also inspect duct insulation and sealing quality, since heat gain or loss along runs can erase performance before air reaches occupied spaces. When airflow and duct integrity are corrected, many “mystery” issues resolve without touching the refrigerant circuit.

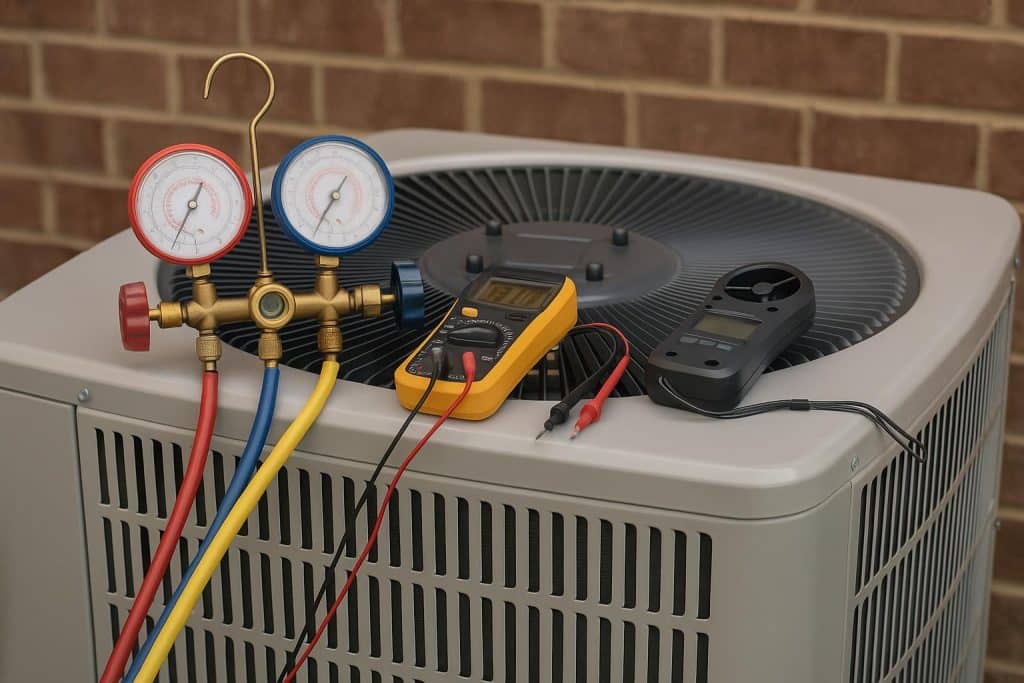

Refrigerant circuit checks and coil performance confirmation

If airflow is verified, contractors move to the refrigeration side to ensure the system is transferring heat properly. On a new AC or heat pump, an incorrect refrigerant charge is a common cause of reduced capacity, humidity problems, and abnormal pressures. Contractors check superheat and subcooling based on the equipment and metering device type, not by feel or a rule of thumb. They also confirm that line sets are correctly sized and properly insulated, because temperature and pressure losses can affect performance, especially on longer runs. Coil condition matters even when equipment is new: construction debris, drywall dust, or protective film left in place can restrict airflow and heat exchange. Outdoor coil placement is reviewed for clearance, recirculation risk, and exposure to dryer vents or tight corners that trap hot air. They verify that the indoor coil is correctly matched to the outdoor unit and that the metering device is appropriate. Any signs of restriction, moisture contamination, or non-condensables lead to deeper diagnostics. The goal is to confirm the system is moving heat at the rate it should, rather than simply “running.”

Controls, sensors, and commissioning of smart features

Modern systems rely on controls as much as hardware, so contractors treat configuration as part of performance. Thermostat placement can create false readings if it’s near kitchens, sunny walls, supply registers, or drafty hallways. Incorrect cycle rate, staging logic, or temperature-swing settings can cause comfort complaints even when the equipment is functioning properly. Variable-speed and communicating systems add layers: airflow profiles, humidity targets, ventilation integration, and zoning logic must match the home’s layout. If zoning is present, contractors check damper operation, bypass strategies, and whether the system is protected from excessive static when zones close. They also review safety switches, float switches, and condensate pump behavior to ensure reliable moisture removal. Commissioning includes confirming that heat pump defrost settings and backup heat lockouts are appropriate for the climate, so the system doesn’t rely on costly auxiliary heat unnecessarily. For systems with indoor air quality add-ons, they verify that UV lights, ERVs/HRVs, and filtration upgrades aren’t unintentionally choking airflow. Proper setup turns advanced features into benefits instead of hidden performance gaps.

The homeowner comfort audit and practical tuning

Even with perfect measurements, contractors still validate performance where it matters: inside the rooms. They perform a comfort audit by comparing temperatures and humidity across zones and floors, checking door undercuts and pressure differences that affect airflow between spaces. They look for building factors that mimic HVAC failure, such as leaky attic hatches, recessed lighting leakage, poorly sealed crawlspace access, or unbalanced exhaust fans that create negative pressure. Sometimes the system is correct, but the homeowner’s expectations aren’t aligned with how the building behaves—especially in older homes where insulation and air sealing lag behind the capabilities of modern equipment. Contractors may fine-tune supply registers, adjust balancing dampers, and recommend filter types that match the duct system’s resistance. They also confirm that maintenance basics are understood from day one: filter changes, keeping returns clear, and using consistent thermostat schedules. A new system often needs a short period of observation after adjustments, because comfort is about trends, not one snapshot. The result is a tuned system that matches the home’s real dynamics.

Turning “new” into truly reliable performance

A new HVAC system should not feel like a puzzle, yet small installation and setup details can create noticeable performance gaps right away. Contractors identify these gaps by validating design assumptions, tracking operating behavior, measuring airflow and static pressure, and confirming refrigerant circuit health with commissioning-level checks. They also address controls configuration, sensor accuracy, and zoning logic, which often matter more than homeowners realize. When measurements are paired with a room-by-room comfort audit, the diagnosis becomes practical: fix what limits delivery, then fine-tune how the system responds to daily life. The payoff is steady temperatures, healthier humidity, quieter operation, and fewer callbacks because issues are solved at the root. Most importantly, early performance verification protects the equipment from stress caused by short cycling, high static, or improper charge. With a disciplined diagnostic process, “new” becomes dependable, and the system can deliver the comfort and efficiency it was purchased for.