Different types of powder metallurgy parts are used in the automotive industry. These parts are created through four steps: powder production, mixing and lending, compacting, and sintering. Some popular PM parts include engineering components, structural parts, grinding wheels, nozzles, electrical bushes, and magnetic and transmission components. These parts are lightweight, strong, durable, and cost-effective; their demand has grown in the last few years.

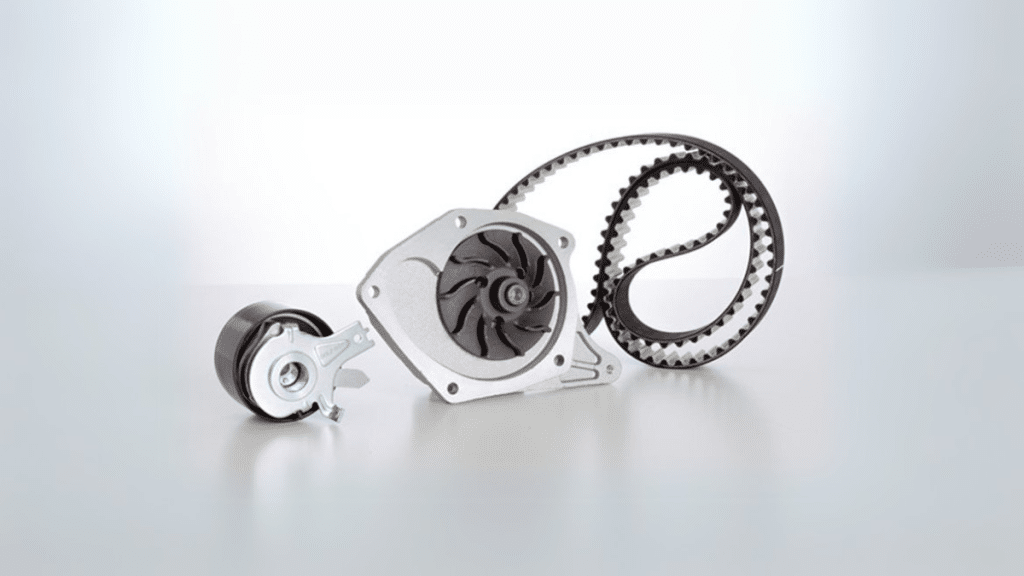

What is a timing belt pulley?

These pulleys are used to synchronize the rotation between the two shafts. For example, you will find the pulley in a vehicle, where it is used to link the crankshafts and the cam. Since the gear body of the pulley is lined with teeth, it ensures that the shaft does not slip and fall. It ensures that it remains in position.

How do you select the right timing belt pulley?

To select a high-quality timing belt pulley, you should consider the following factors:

- Shaft speed, types of driver and power of transmission,

- Driven machinery ratio, drive, and shaft speed,

- The total number of hours the pulley will be used and whether there is any special operating condition,

- The diameter of the shaft and any specific restriction that can affect the diameter and width of the pulley.

What selection procedure should be followed when shortlisting the timing belt pulley?

There are several steps that you need to follow:

- Whatever the driven pulley is, the transmission power is always related to the smallest pulley,

- If you have to choose from a range of pulleys, you need to consider the combination of the given drive. A large pulley reduces the belt’s flexibility, thereby enhancing its life. Generally, narrow belts are used in large pulleys, which can be expensive.

- When the center distance is eight times more than the smaller pulley, both should be flanged.

- You need a loafer pulley when the center adjustment of the shaft is inadequate.

- When the belt speed is more than thirty meters per second, you should not use an iron pulley.

The selection of timing belt pulley:

While the above are some of the common concerns about the operating environment, you need to make sure that you check out the other applications.

- Drive ratio: This can be ensured by dividing the speed of the faster shaft with the slower shaft. If the speed is lower than the driven shaft, then drive.

- Selection of the belt pitch: You need to choose a belt pitch based on the smallest pulley’s speed. However, if the room is limited, you need to ensure that the belt pitch is correct for a well-proportioned drive.

- Distance between the length of the center and belt: To calculate the belt length and the center distance, you need to consider the belt size and the number of teeth in the pulleys.

Hence, before choosing the kind of belt pulley, you should consider all the above requirements. As already discussed, the operating environment can impact the belt pulley’s performance, especially when the temperature is extreme. However, when the temperature is reasonable, the timing belt pulley is your best choice.