In today’s fast-moving industrial world, manufacturing is no longer just about mass production — it’s about innovation, efficiency, and adaptability. Modern factories are becoming smarter, more automated, and customer-focused. At the heart of this transformation lies product engineering, a discipline that combines creativity, technology, and data to create products that meet real-world demands. From conceptual design to post-production logistics, product design engineering ensures that every step of the process adds value and reduces waste.

Understanding Product Engineering

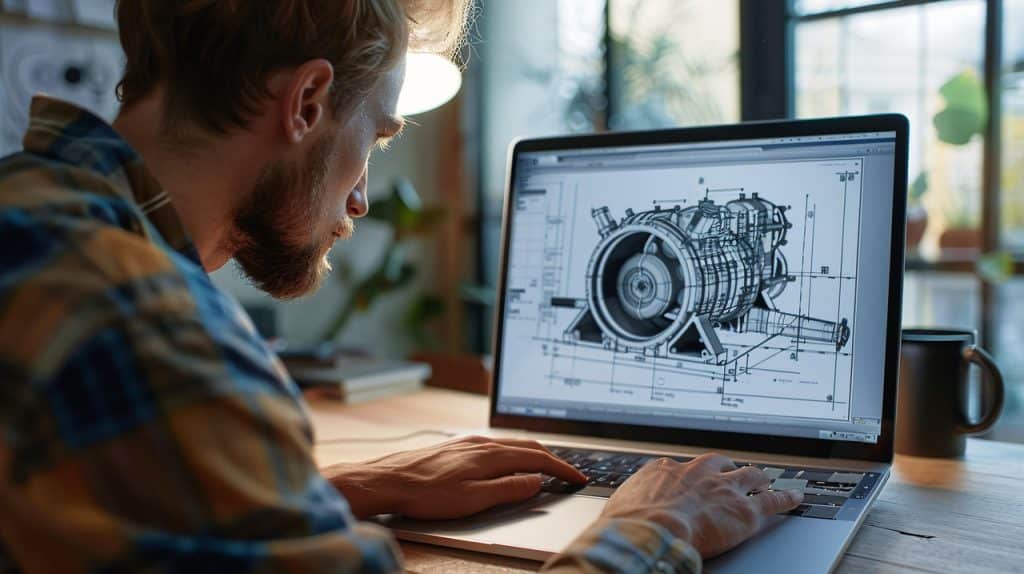

Product engineering refers to the complete process of designing, developing, testing, and manufacturing a product. It bridges the gap between an idea and a tangible product ready for the market. Engineers use advanced tools, such as 3D modeling, simulations, and digital twins, to predict performance and identify flaws before physical prototypes are made.

This approach saves time, reduces costs, and helps companies deliver higher-quality products. In simple terms, product engineering transforms creative ideas into manufacturable solutions that meet customer needs and business goals.

The Role of Product Design Engineering

One of the most critical aspects of product engineering is product design engineering. It focuses on how a product looks, functions, and performs throughout its lifecycle. Designers consider factors such as materials, ergonomics, safety, sustainability, and cost-effectiveness during the design phase.

For example, a consumer electronics company may use product design engineering to create a smartphone that is not only sleek and durable but also easy to repair and recycle. By combining aesthetics with function, engineers ensure that products are both visually appealing and practical for mass production.

Integrating Technology and Innovation

Modern manufacturing is heavily influenced by emerging technologies like artificial intelligence (AI), Internet of Things (IoT), and additive manufacturing (3D printing). Product engineering plays a key role in integrating these technologies seamlessly into production systems.

For instance, digital twins — virtual replicas of physical products — allow engineers to test performance in a simulated environment. IoT sensors in machinery help track quality in real-time, while AI algorithms optimize production schedules to minimize downtime. Together, these innovations improve productivity and reduce manufacturing costs.

The Connection Between Product Engineering and Manufacturing Efficiency

Efficiency in manufacturing depends on how well product designs are optimized for production. A well-engineered product is easier to assemble, uses fewer resources, and has lower defect rates.

Product engineers analyze each component, material, and process to ensure that the design is both efficient and sustainable. They work closely with manufacturers to refine designs for better assembly lines, which helps reduce waste and increase output. This close collaboration makes manufacturing more flexible and resilient — especially in industries like automotive, electronics, and consumer goods.

The Importance of Sustainable Engineering

Sustainability has become a driving force in modern product engineering. Engineers are now focusing on eco-friendly materials, energy-efficient production methods, and recyclable product designs. Sustainable product design not only benefits the environment but also appeals to conscious consumers and reduces long-term costs.

Manufacturers adopting sustainable engineering practices gain a competitive advantage and align with global goals to reduce carbon emissions. This green shift is an essential step toward responsible and future-proof manufacturing.

From Design to Delivery: The Role of 3PL Storage + Logistics

Once a product is engineered and manufactured, the next challenge is managing its storage and distribution efficiently. That’s where 3PL Storage + Logistics (Third-Party Logistics) comes into play. These services handle everything from inventory management to transportation and warehousing, allowing manufacturers to focus on what they do best — creating quality products.

By integrating 3PL Storage + Logistics into the product engineering cycle, companies ensure that products are not only designed and built efficiently but also delivered on time and in perfect condition. For example, a manufacturer of high-tech machinery can rely on a 3PL provider to store and distribute sensitive components under optimal conditions, ensuring reliability and customer satisfaction.

Collaboration Across Disciplines

Modern manufacturing is a collaborative ecosystem involving engineers, designers, suppliers, and logistics partners. Product engineering sits at the center of this network, coordinating efforts to ensure smooth transitions between design, production, and delivery.

This interdisciplinary approach helps identify problems early, improves communication, and speeds up time-to-market. Collaboration between product design engineering teams and logistics specialists — including 3PL Storage + Logistics providers — ensures that designs are not only functional but also practical to ship, store, and assemble globally.

Challenges and Future Directions

While product engineering offers immense benefits, it also comes with challenges. Keeping up with rapid technological changes, managing data security, and ensuring cost efficiency can be difficult for manufacturers. Moreover, the global supply chain requires adaptability to disruptions, such as material shortages or geopolitical tensions.

However, the future looks promising. With advancements in automation, smart materials, and AI-driven design, product engineering will continue to drive innovation in manufacturing. Companies that embrace these changes will be better equipped to thrive in an increasingly competitive market.

Why Product Engineering Matters More Than Ever

In today’s competitive global economy, product engineering is not just a technical discipline — it’s a strategic advantage. It determines how fast companies can bring new products to market, how well they meet customer expectations, and how efficiently they can scale production.

By combining innovation in product design engineering with strong logistics partnerships such as 3PL Storage + Logistics, businesses can create a seamless end-to-end process — from concept to customer delivery. This approach ensures consistent quality, reduces operational costs, and enhances brand reputation.

Conclusion: Engineering the Future of Manufacturing

The manufacturing landscape is evolving rapidly, and product engineering is the force driving that transformation. From smart designs and sustainable materials to digital twins and optimized supply chains, every element contributes to greater innovation and efficiency.