Automation is a cornerstone of modern industry, driving productivity, precision, and consistent advancements. In this evolving landscape, the choice of components significantly impacts the efficiency and reliability of automated systems. One critical component is the actuator, which converts energy into motion to perform mechanical tasks.

Rotary electric actuators are pivotal in enhancing automation systems. They convert electrical energy into rotary motion, precisely controlling angular movement. Their versatility, efficiency, and ease of integration make them the best choice in applications ranging from robotics to industrial machinery.

Delivering Precision and Control

Rotary electric actuators excel in applications requiring high precision and repeatability. Unlike pneumatic or hydraulic actuators, which rely on fluid dynamics, electric actuators provide consistent and predictable performance. Advanced control systems allow for fine adjustments to position, speed, and torque, ensuring accurate operation even in complex tasks.

This level of precision is particularly beneficial in industries such as aerospace, automotive, and electronics manufacturing, where tolerances are tight, and errors can lead to significant losses. Rotary electric actuators ensure that automated systems meet stringent quality standards.

Enhancing Energy Efficiency

Energy efficiency is a key consideration in automation, as it directly affects operational costs and environmental impact. Rotary electric actuators are highly efficient, converting significant electrical energy into mechanical motion. Their design eliminates energy-intensive compressors or pumps, as in pneumatic and hydraulic systems.

In addition to their inherent efficiency, these actuators can operate on demand, consuming energy only when movement is required. This feature reduces idle energy consumption, making them an environmentally friendly option for sustainable manufacturing practices.

Simplifying Integration and Maintenance

Rotary electric actuators are designed for seamless integration into various automation systems. Their compact and modular construction allows easy installation, even in tight spaces. Standardized mounting options and communication interfaces simplify the process, enabling quick setup and commissioning.

Maintenance requirements are minimal compared to pneumatic and hydraulic alternatives. Electric actuators lack seals, valves, and fluid reservoirs and are prone to wear and leakage. This reduces downtime and maintenance costs, increasing overall system reliability.

Offering Versatility Across Applications

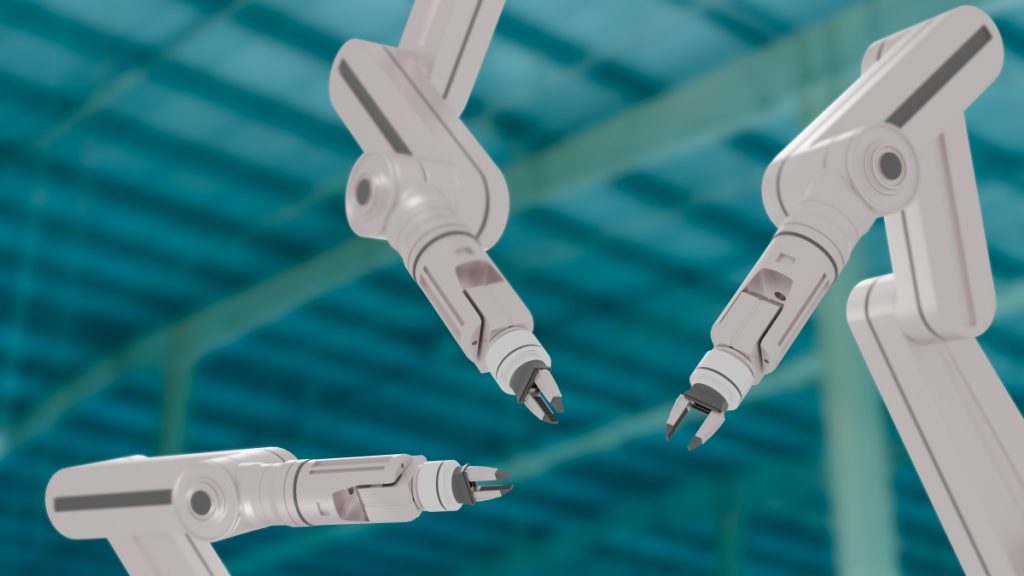

Rotary electric actuators are adaptable and suitable for a wide range of applications. In robotics, they drive joints and arms precisely, enabling smooth and coordinated movements. In material handling systems, they control conveyors, sorters, and pick-and-place mechanisms, optimizing throughput and accuracy.

Other applications include valve automation in process industries, where rotary actuators ensure precise flow control, and positioning systems in CNC machines, where they provide accurate rotational movement. Their versatility allows them to meet diverse industry needs, enhancing overall system capabilities.

Supporting Advanced Automation Technologies

The rise of smart manufacturing and Industry 4.0 has placed new demands on automation components. Rotary electric actuators are well-suited for these environments, offering compatibility with advanced control systems and IoT platforms. Their ability to provide real-time feedback on position, speed, and torque enables predictive maintenance and optimized performance.

In addition, these actuators can be integrated with machine learning algorithms to adapt to changing conditions and improve efficiency over time. This makes them a crucial component in the development of intelligent automation solutions.

Reducing Environmental Impact

Sustainability is an important consideration in industrial automation. Rotary electric actuators contribute to reducing environmental impact through their energy-efficient operation and low-maintenance design. Their electricity use as a power source eliminates the need for oil-based fluids, reducing the risk of leaks and contamination.

Furthermore, these actuators offer precise control that minimizes waste in manufacturing processes. Accurate positioning and movement ensure that materials are handled efficiently, reducing scrap and improving resource utilization.

Investing in Reliable Performance

Automation systems must operate reliably to meet production demands and avoid costly downtime. Rotary electric actuators are designed for durability, with robust construction and advanced materials that withstand harsh operating conditions. Their consistent performance ensures long-term reliability, making them a cost-effective choice for demanding applications.

Integrated sensors enable regular monitoring and diagnostics, further enhancing their dependability. Early detection of possible issues allows for proactive maintenance, preventing unexpected failures and extending the actuator’s lifespan.

Embrace the Future with Rotary Electric Actuators

Rotary electric actuators transform automation by delivering precision, efficiency, and versatility. Their ability to meet the demands of modern manufacturing and adapt to emerging technologies positions them as an essential component in any automated system. From reducing energy consumption to improving system reliability, these actuators empower industries to achieve better outcomes.

Integrate rotary electric actuators into your automation strategy today. Leverage their benefits to optimize performance, reduce costs, and stay ahead in a competitive market. The future of efficient and sustainable automation begins with the right components.