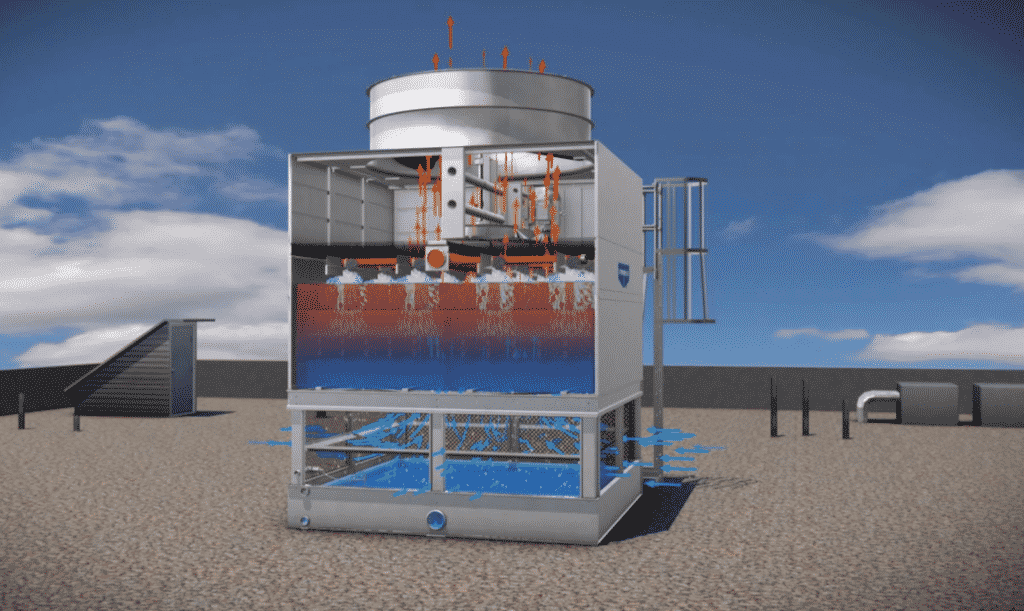

These days, the cooling system is a necessity, especially for industries that someway depend on water. A heat swapper brings air and boiling water in direct contact to normalize the temperature. A cooling tower is the perfect mechanism to help you treat your equipment, as well as save water. You definitely need a good cooling tower from international cooling tower if you are looking for a cooling tower for your factory. However, when looking for a perfect cooling tower for your factory, there are a number of factors that you should consider.

Here are some of the factors you need to consider when choosing a cooling tower for your company.

1. Analyze your requirements

Analyzing your requirement before the search is very important. When scrutinizing your requirements, you need to consider the size, capacity, and power before you make the actual deal. Analyzing your requirements first can help to take you a step closer to the solution. You can discuss everything regarding your needs with the supplier in order to arrive at the right solution.

2. The quality of the utilized material

The material of the tower plays an important role when it comes to the cooling tower’s functioning and effectiveness. An industrial cooling tower made from high-quality material can help to reduce the maintenance cost. The boiling salt water can corrode the tower material, making it fragile. The most recommended materials are galvanized steel, stainless steel, fiber-reinforced plastic [FRP], and other high-quality steel materials. If you want value for your money, ensure that you invest in high-quality materials for your cooling towers.

Let’s look at the materials

Galvanized steel: the traditional cooling towers use steel sheets coated by zinc, and they are susceptible to corrosion, rust, and pH issues. Again, seam leak and biofilm hazard become evident. Cooling towers made of galvanized steel have about 5-6 years of life expectancy. They are also a cost-effective option.

Stainless steel: this is a better option compared to the galvanized steel cooling towers. These cooling towers can work efficiently for up to 15 years. They can be used in places with harsh weather conditions, where water hardness is greater. But seam leakage can be quite a challenge due to the contraction and expansion that occurs because of weather exposure.

Fiber-reinforced plastic [FRP]: FRP cooling towers are the most durable type of cooling towers. They can go past a 30-year life expectancy in some brands. Fiber-reinforced plastic towers are more corrosion-resistant, seamless, lea k-proof due to their bathtub design, and they come with UV protected coating. Therefore, no leak problems will arise.

3. Water flow rate

The capacity and flow rate of water has a significant impact on the performance of any cooling tower. There are two types of water flow, including Counter Flow and Cross Flow. In Counter flow, the air suction from the fan is against the falling water. The tower has a little area of coverage with an even distribution through the fill materials. This type of tower may also include pressurized water distribution.

In cross flow, as the falling water flow the fills, the hot air that flows across the falling water is pulled out by the fan through the gravity distribution. This type of tower has huge area coverage.

Other factors to consider when choosing a cooling tower

- The amount of cooling load the tower can hold

- The water temperature entry and recycling

- Wet-bulb temperature [WBT]

- Lowest temperature after treatment

- Space coverage

- Bearable water quality

- Noise level restrictions

Final words

Setting an appointment with a cooling tower manufacturer can help you understand the different designs of cooling towers and additions the manufacturer can add. If you are looking for a high-quality cooling tower that will give you value for your money, the fiber-reinforced plastic towers are the best option. Remember to keep these tips in mind when buying a cooling tower, this way; you will make this investment worth your money.