Lithium iron phosphate (LFP) batteries are gaining widespread popularity due to their safety, longevity, and cost-effectiveness. These batteries are widely used in electric vehicles (EVs), various portable electronic and renewable energy storage systems. Their stable chemical composition reduces the risk of overheating, which makes them ideal for applications where safety is paramount. Among the various types of lithium batteries, LFP cells come in different forms, such as cylindrical and prismatic LFP cells, each suited to specific needs.

However, as the demand for reliable and efficient energy storage grows, choosing the right LFP battery manufacturer becomes crucial. The article delves into the components of an LFP battery and discusses the aspects you should consider when selecting an LFP battery manufacturer. Understanding these aspects will help you make an informed decision, ensuring you choose a reliable partner for your energy storage needs.

What Are the Components of LFP Battery?

LFP batteries, or lithium iron phosphate batteries, are structured in a multi-layered format comprising cells, modules, and packs.

- Cell: The fundamental unit of an LFP battery contains an anode, a cathode (made of lithium iron phosphate), an electrolyte, and a separator. These cells are available in various formats, including the cylindrical cell and prismatic LFP cell, each tailored for specific applications based on their performance characteristics.

- Module: Modules combine multiple cells to optimize performance by balancing charge and discharge rates. They incorporate safety features to regulate temperature and voltage, which is crucial for maintaining the battery system’s efficiency and safety.

- Pack: Assembled from modules, packs are complete battery units used in various applications like electric vehicles and energy storage systems. They include additional components such as cooling systems, battery management systems (BMS), and protective housing, customized to meet specific power and energy demands.

Choosing a reliable supplier of LFP cells is essential as it affects the performance, safety, and lifespan of the battery pack. A reputable LFP battery manufacturer guarantees high manufacturing standards, ensuring that each cell is produced with precision.

This brings us to the next part: how to choose a good LFP battery cell manufacturer?

Factors to Choose a Good LFP Battery Cell Manufacturer

1. Factory Scale and Production Capability

Evaluate the LFP battery manufacturer’s facility size and ability to meet large-scale production demands efficiently.

2. Grade A Quality

Always prefer an LFP battery manufacturer known for producing high-quality grade A cells. Grade A cells are new, unused, and meet the highest quality standards, while Grade B cells may be recycled, used, or have minor defects affecting their performance and longevity.

3. Supply Chain, Logistic Network, and Delivery Time

Ensure the LFP battery manufacturer has a robust supply chain, efficient logistics, and reliable delivery schedules to meet your needs.

4. Certifications

Check for industry-standard certifications like ISO, UL, and CE, which indicate compliance with safety and quality regulations.

5. R&D Innovation

Look for an LFP battery manufacturer that invests in research and development to continually improve their products, services and stay ahead in technological advancements.

Famous LFP Manufacturers in The World

Here are the top five LFP manufacturers who supply high–quality certified batteries, ensuring reliability, safety, and performance.

- CATL: Contemporary Amperex Technology Co. Limited (CATL) leads as the world’s largest lithium-ion battery manufacturer, producing 96.7 GWh of EV batteries annually. Renowned for its scale and innovation, CATL is a driving force in the automotive battery industry.

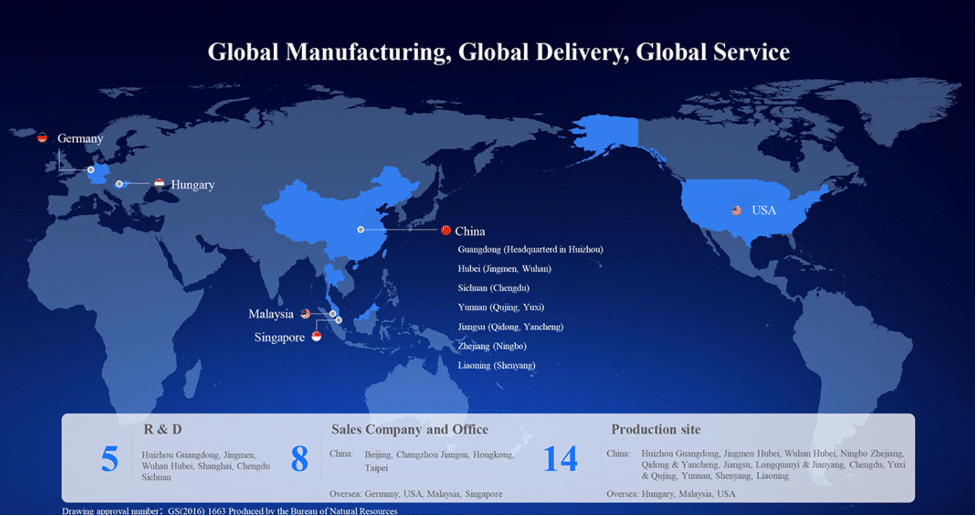

- EVE: EVE Energy is a prominent innovator in the EV battery industry, addressing complex challenges with over 5,500 researchers and 7,900+ patents. The company ensures class A battery quality through large-scale production and stringent quality control, holding certifications like ISO and UL. Supported by a strong global supply chain, including warehouses in Germany, EVE excels in efficient worldwide distribution.

- LG: LG has diversified its battery manufacturing beyond EVs, producing a wide range of batteries for phones and cars. Their batteries are designed for maximum capacity and efficiency, with electric car models capable of over 500 km on a single charge, showcasing LG’s advanced battery technology capabilities.

- Panasonic: Panasonic’s lithium-ion batteries are crucial components in hybrid and electric vehicles, notably including Tesla, which exclusively relies on Panasonic for its battery solutions. Known for their efficiency and eco-friendliness, Panasonic collaborates closely with automakers to ensure top performance and environmental responsibility.

- BYD: BYD Ltd, known as Build Your Dreams, is dedicated to revolutionizing EV battery safety standards. Their commitment to enhancing safety makes BYD a significant player in the battery industry.

EVE Energy leads the EV battery industry with its groundbreaking technology and extensive portfolio. With 23 years of experience, the company upholds exceptional standards through large-scale production and rigorous quality control, bringing them third place in shipments of global energy storage in 2023, fourth place in shipments of cylindrical batteries, and the high rank in niches of small lithium-ion batteries. In 2023, the installed capacity of EVE’s power battery cells grows the fastest in the global market.

EVE’s robust global distribution is supported by partnerships with renowned companies like GOODWE, Caterpillar, Mercedes-Benz, DELTA, BMW, and FOTON.

With EVE Energy, innovation powers every mile, and excellence drives the future.