3D printing has revolutionised the way we create and prototype, offering a world of possibilities right at our fingertips. One of the most crucial decisions you’ll make in your 3D printing journey is choosing the right filament. With a variety of materials available, each with its own unique properties and applications, selecting the right one can significantly impact the quality and durability of your prints.

In this blog post, we’ll delve into the most popular filament materials used in 3D printing, discuss the various factors to consider when selecting a filament, and explore the benefits of using high-quality filament for your projects.

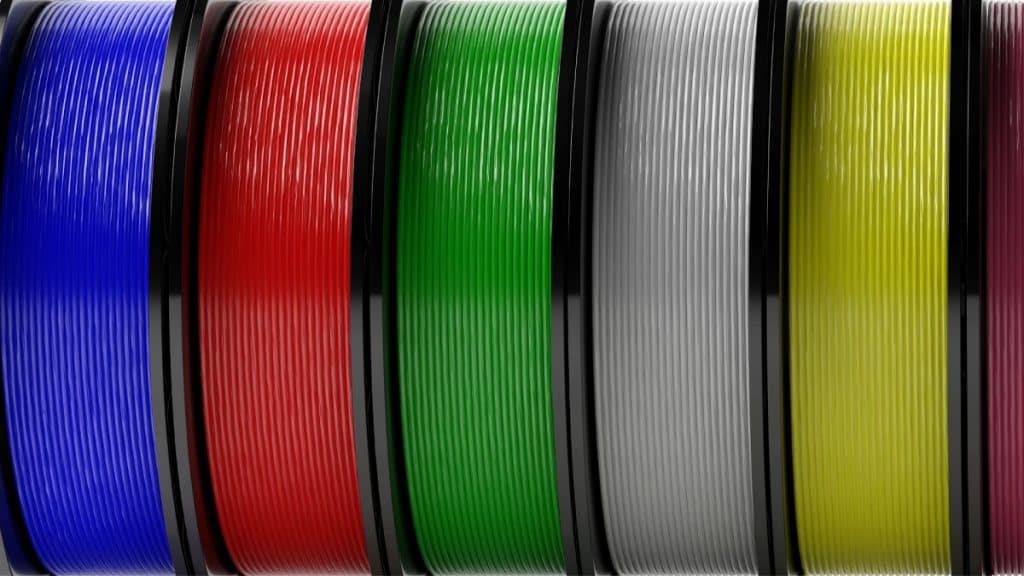

Popular Filament Materials

PLA (Polylactic Acid)

PLA is the most popular and user-friendly filament for 3D printing. Derived from renewable resources like corn starch or sugarcane, it is biodegradable and environmentally friendly. PLA 3D printing filament is known for its ease of use, low warping issues, and excellent print quality. It’s ideal for beginners and for creating detailed, aesthetically pleasing objects.

ABS (Acrylonitrile Butadiene Styrene)

ABS is a robust and durable filament that can withstand higher temperatures and physical stress compared to PLA. It is widely used in industrial applications due to its strength and flexibility. However, ABS can be challenging to print with because it tends to warp and release fumes, necessitating a well-ventilated environment or an enclosed printer.

PETG (Polyethylene Terephthalate Glycol)

PETG combines the best qualities of PLA and ABS – it offers ease of use and minimal warping, similar to PLA, while providing the strength and temperature resistance akin to ABS. PETG is also food-safe and has excellent layer adhesion, making it suitable for a wide range of applications from household items to mechanical parts.

Keep These Factors in Mind When Selecting Filament

When choosing a filament for your 3D printing projects, several factors come into play. Here are some key considerations to keep in mind:

- Print Temperature: Different filaments require different printing temperatures – PLA typically prints at 180-220°C, ABS at 220-250°C, and PETG at 230-250°C. Ensure your 3D printer can reach and maintain the necessary temperatures for the filament you choose.

- Bed Adhesion and Warping: Some filaments are more prone to warping and require special measures for bed adhesion. PLA is relatively forgiving, while ABS needs a heated bed and often benefits from an enclosed build space to prevent warping. PETG usually requires a heated bed and can adhere very strongly to some surfaces, sometimes necessitating the use of a release agent.

- Strength and Flexibility: Consider the mechanical properties of the filament. If your project demands high strength and flexibility, ABS or PETG might be more suitable. For decorative items or prototypes where intricate details are important, PLA is often the best choice.

- Environmental Impact: If environmental sustainability is a priority, PLA is the way to go. Its biodegradable nature makes it the most eco-friendly option among the common filaments. PETG is also recyclable, though not biodegradable, while ABS is the least environmentally friendly due to its petroleum-based origins.

- Post-Processing: Some filaments are easier to post-process than others. PLA sands and paints well but can be brittle. ABS can be smoothed using acetone vapour, giving a glossy finish, and PETG can be polished and is resistant to solvents.

Why Invest in High-Quality Filaments Over Inferior Ones?

Investing in high-quality filament can make a significant difference in your 3D printing projects. Here are some advantages of using premium filament:

- Consistent Diameter: High-quality filaments have a consistent diameter, ensuring smooth and reliable extrusion. This consistency reduces the likelihood of clogging and results in more accurate prints with finer details.

- Purity and Composition: Premium filaments are made from pure materials with fewer impurities; this purity translates to better print quality and reduced risk of extrusion problems. Impurities in lower-quality filaments can cause inconsistent printing and potentially damage your printer.

- Enhanced Mechanical Properties: Top-tier filaments offer superior mechanical properties, including increased strength, flexibility, and durability. This enhancement is critical for functional parts that must withstand stress and wear.

- Colour and Finish: High-quality filaments often come in a broader range of vibrant colours and finishes. They produce smoother surfaces and more uniform colouration, enhancing the aesthetic appeal of your prints.

- Reduced Printing Issues: Using high-quality filament can minimise common printing issues such as warping, stringing, and layer adhesion problems. This reduction means fewer failed prints, saving you time and material.

Ready to get started?

As you can see, choosing the right filament for your 3D printer is crucial for achieving the best results in your projects. Investing in high-quality filaments will not only enhance the quality of your prints, but also ensure a smoother and more enjoyable 3D printing experience. Whether you’re a hobbyist, a professional or you’re just getting started, the right filament can unlock new possibilities and take your creations to the next level.