Sourcing replacement parts can be a daunting task, particularly when critical components are no longer in production. This is part of the challenge faced by industrial facilities with legacy automation systems. The problem becomes more complicated as a failure can bring an operation to a complete standstill and have a significant impact on productivity and profitability.

Disaster strikes when there is no immediate supply chain to fall back on. A forward-thinking and strategic plan to parts management and procurement, especially in the case of the older systems, will help tremendously.

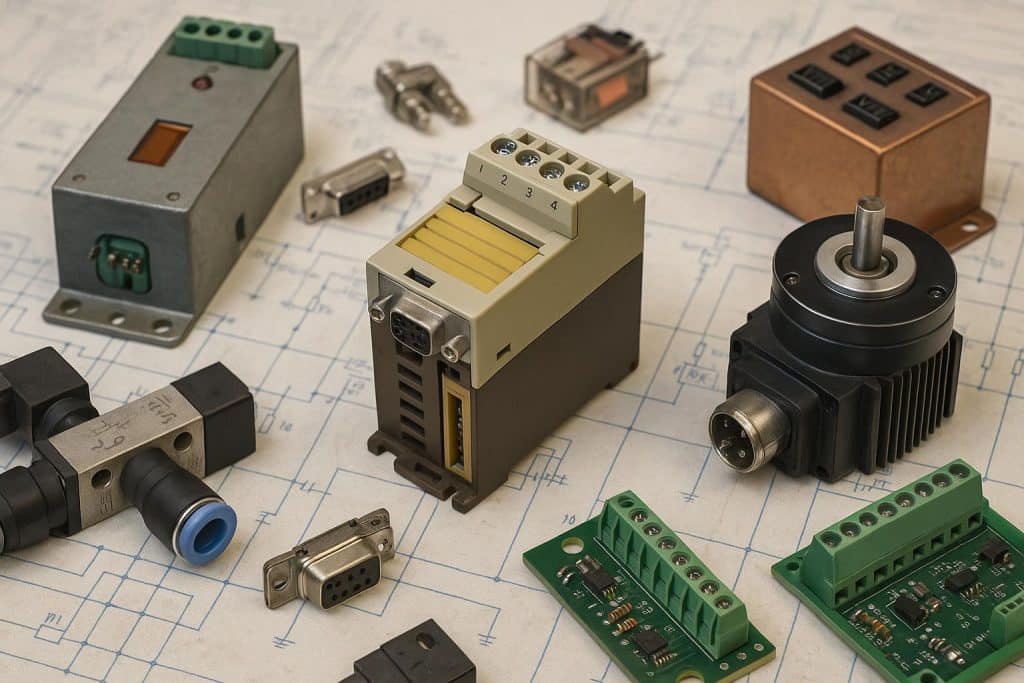

Being able to track down and access replacement parts such as control system spares, HMIs, relays, (and others you’ll find at reputable providers such as Classic Automation) is key to making sure that these systems stay in operation and aren’t crippled by lengthy downtimes.

Conduct a Comprehensive Parts Audit

An effective and thorough audit of all the equipment and spares in the facility is the best way to kick-start a successful legacy automation management process. During the audit, every component is meticulously logged, and you should identify which ones are going to be phased out, and which are absolutely essential to the operation, taking note of the part numbers, manufacturer, and specifications.

This makes it far simpler to find the right replacement parts and eliminates any confusion. A well-executed parts audit also helps predict potential risks, enabling the maintenance team to plan for and proactively replace parts that are wearing out.

Partner with Specialized Distributors and Reputable Vendors

When it comes to locating and supplying these hard-to-find components, one option is to turn to specialized distributors and vendors. They know the inner workings of these older systems keep massive libraries of inventory, and often have access to global networks of supply that most companies don’t. Distributors who are known for their reliability and quality assurance add real value to the procurement process.

They can test and verify the parts before sending them your way, and establish long-term relationships, granting priority access to limited stock. In terms of refurbishment and replacement of parts in automation systems, the reputable resale sector plays a huge role in restoring and retesting legacy components to meet the original manufacturers’ standards.

Reconditioned parts such as sensors, power supplies, and control system spares go through rigorous testing and have the capacity to offer highly reliable performance at a fraction of the cost.

Explore Reverse Engineering and Custom Manufacturing

When new parts are no longer available, and used/refurbished ones cannot be found, reverse engineering and custom manufacturing can be the next possible solution. Today’s advanced design and manufacturing methods allow engineers to mirror existing components with high accuracy using 3D scanning and modeling tools.

Customized manufacturing from highly trained engineering firms or original equipment manufacturer partnerships can also fill in the gaps in the supply chain. It’s usually a more expensive option, but it guarantees long-term availability and gives control over the parts that run the critical systems.

Finding Control System Spares and Other Difficult-to-Locate Parts Is Crucial to Continuing Operations

Combining proactive oversight, a circle of trusted providers, and refurbishment services will reduce the likelihood of breakdowns and give organizations the parts they need to keep going. And regular reviews of the plan ensure that it stays on track with the latest technology and market trends.