On the motorcycle, swing arm pivot bearings just so happen to be one of the most important parts because they provide stability and smoothness in the rear suspension. The bearings provide free rotation on the swing arm, and this encourages peak handling, comfort, and performance; thus, there is a need for the pivot bearings to be effective. If the motorcycle’s rear suspension were stiff, unstable, and hard to handle, then the pivot bearings would not be functioning.

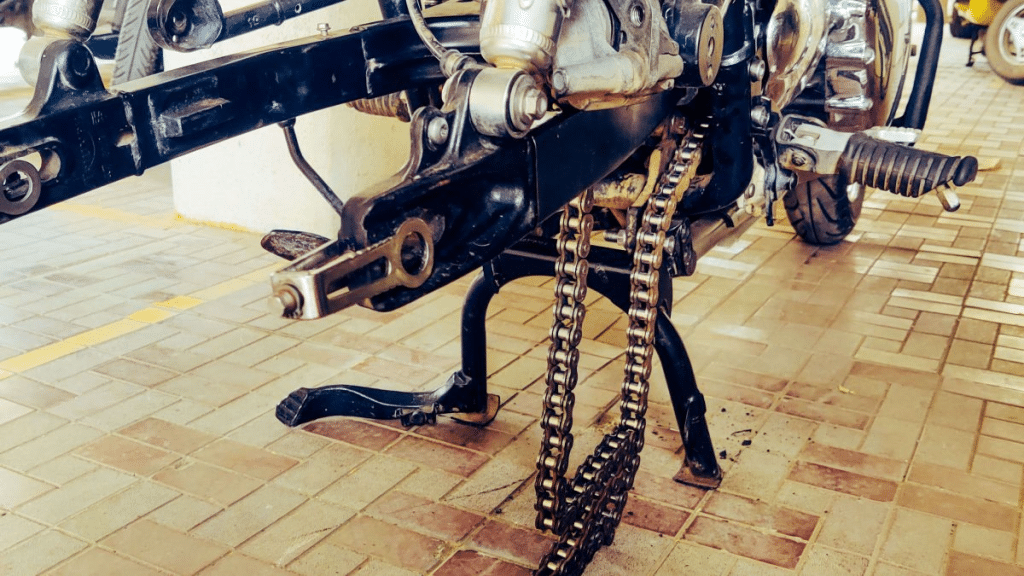

The swing arm itself is a structural component of a motorcycle suspension system that links the rear wheel to the frame. It bobs back and forth with road bumps, attenuating shocks and keeping the motorcycle stable. Pivot bearings at the point where the swing arm meets the frame guarantee smooth and stable motion. These bearings will degrade with time from mud, water, and normal wear and tear and cause sloppy suspension and harsh ride.

A variety of swing arm pivot bearings are used based on the design of the motorcycle. Needle roller bearings, high load with a low profile package, and plain bushings, fewer but adequate for some applications, are most commonly used. Sealed bearings are used by some racing bicycles in general to reduce maintenance requirement and suspension component life cycle. Whatever is employed, checkup and maintenance at set intervals have to be done to keep them working.

Overplay on the rear wheel is amongst the worst indication of swing arm pivot bearing wear. Loose or loose rear bike indicates that bearings have dried up or worn out. The other symptoms include strange noises like clicking or creaking when riding over bumps, uneven wear of the rear tyres, and general instability during cornering. If not repaired, a bearing failure will wear out the bearing, reducing the quality of the handling of the bike and, worst case, safety.

Also completed is i.e., replacement of swing arm pivot bearings in motorbike repair: swing arm has to be lifted to reach bearing to overhaul/renew/grease in severe wear. Installing quality bearings within spec to achieve an optimum fit and life is required. In new bearing installation, proper grease application prevents premature wear without permitting dirt and water entry.

UK riders are sometimes forced to ride through wet and muddy terrain, which has a tendency to create excessive wear in swing arm pivot bearings. Regular cleaning and lubrication of bearings will make their lifespan longer and provide optimum performance from them. Proper sealing of bearings and using water-resistant grease will also prevent moisture from entering and thereby prevent corrosion. Most motorcyclists also inspect their bearings with regular maintenance, particularly prior to long riding times or track days when the suspension system is more stressed.

Selecting quality replacement bearings is crucial to performance and durability. Several quality builders provide heavy-duty pivot bearing kits for some motorcycle models. Heavy-duty or sealed bearings will be more advantageous to motorcycle owners who ride motorcycles extensively off-road or in harsh weather. Installation is critical, and if in doubt, having a professional mechanic install guarantees bearings are installed correctly, avoiding problems such as misalignment or over-tightening.

The swing arm pivot bearings are an important contributor to the overall handling and comfort of a motorcycle. Maintaining them in good condition in the right way not only enhances the quality of the ride but also enhances safety and assists in extending the life of the suspension system. Whether as routine inspections, lubricating of existing bearings, or changing existing bearings which are worn out, routine servicing of this component keeps the motorcycle stable, responsive, and road-worthy.