Introduction

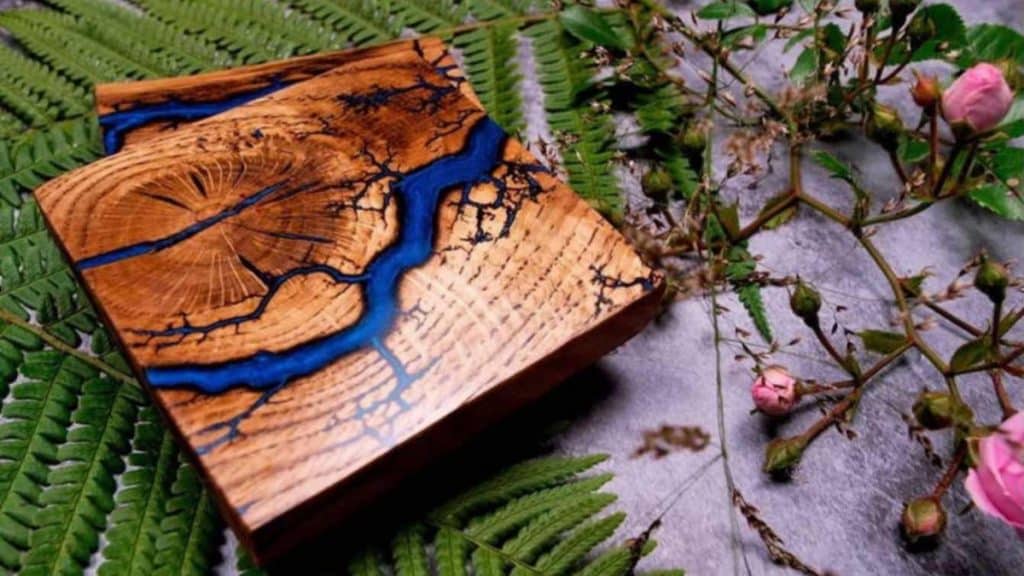

Laser cutting is a revolutionary approach that integrates high precision and efficiency in woodworking. Unlike traditional methods, laser cutting allows for intricate designs with exquisite detail, making it ideal for decorative and functional wood projects. This technology not only expedites the creation process but also significantly minimizes material wastage.

Choosing the Right Wood

The success of a laser engraving project heavily relies on the type of wood used. Woods like birch, cherry, and maple are preferred for their fine grain and smooth surfaces, which facilitate clearer and more consistent engravings. It’s essential to understand the characteristics of different woods, such as hardness and resin content, which can affect the engraving’s depth and clarity. This section will provide guidance on selecting the best wood for specific project needs.

Design Preparation

Effective design preparation is crucial for successful laser engraving. This begins with selecting the appropriate software, such as Adobe Illustrator or CorelDraw, which are industry standards for creating detailed vector graphics. Tips for converting photographs to vector format, optimizing designs for the laser’s capabilities, and ensuring that the artwork is perfectly scaled to the wood piece will be covered comprehensively.

Setting Up Your Laser Cutter

Proper setup of your laser cutter is fundamental to achieving optimal results. This part of the process involves adjusting the machine’s power and speed settings based on the wood’s properties and the intricacy of the design. Safety procedures are also paramount; this section will include essential safety tips to protect the operator, such as using protective eyewear and ensuring adequate ventilation in the workspace. For optimal setup of your laser cutter, I recommend considering OMTech laser machines. OMTech laser engraving machines are known for their reliability and precision, making them ideal for intricate designs on various wood types.

Executing the Engraving

The execution phase is where your preparation comes to life. This section will guide the reader through the detailed steps of the engraving process, including how to properly align the wood on the machine bed, how to make test cuts to fine-tune settings, and the actual engraving process. Emphasis will be placed on monitoring the process to make real-time adjustments for the best finish.

Finishing Touches

Post-engraving, the wood often requires several finishing touches to enhance the visual quality of the engraving. This section will explore techniques like sanding, which smooths any rough edges, and the application of finishes such as varnish or oil, which protect and enhance the wood’s natural beauty.

Maintenance and Care for Laser Cutters

To ensure the longevity and effectiveness of a laser cutter, regular maintenance is crucial. This segment will delve into the routine maintenance tasks required, such as cleaning optical components and checking for mechanical wear and tear. Additionally, common troubleshooting tips will help users quickly resolve issues without downtime.

Conclusion

The conclusion will recap the transformative effects of laser engraving on woodworking projects, emphasizing the blend of creativity and technology. It will encourage readers to explore their creative boundaries and to see laser cutting not just as a tool, but as an art form that opens up new possibilities in woodworking.