Medical tubing is a critical component in healthcare, found in applications ranging from catheters and IV lines to feeding tubes and respiratory devices. The production of medical-grade tubing requires precision, reliability, and the highest standards of quality to ensure patient safety. One of the most effective methods for producing medical tubing is through extrusion. Let’s explore the process of medical tubing extrusion and the key equipment required.

The Medical Tubing Extrusion Process

Extrusion is a manufacturing process that involves forcing raw material—usually thermoplastic resins like PVC, polyethylene, or silicone—through a die to create long, continuous shapes, such as tubes. For medical tubing, the extrusion process is tightly controlled to ensure the tubing meets precise dimensional and material specifications. The process begins by feeding medical-grade polymers into an extruder, where they are melted and then pushed through a specialized die to form a tube. Cooling and calibrating systems immediately follow the extrusion step to ensure the tubing retains its shape and dimensions.

Since medical tubing can be as thin as a few millimeters or designed with complex features such as multi-lumen structures (multiple channels within a single tube), the extrusion process must be fine-tuned to the specific requirements of each application. The resulting tubing must be free from defects like kinks, bubbles, or cracks, which can affect its performance in a clinical setting.

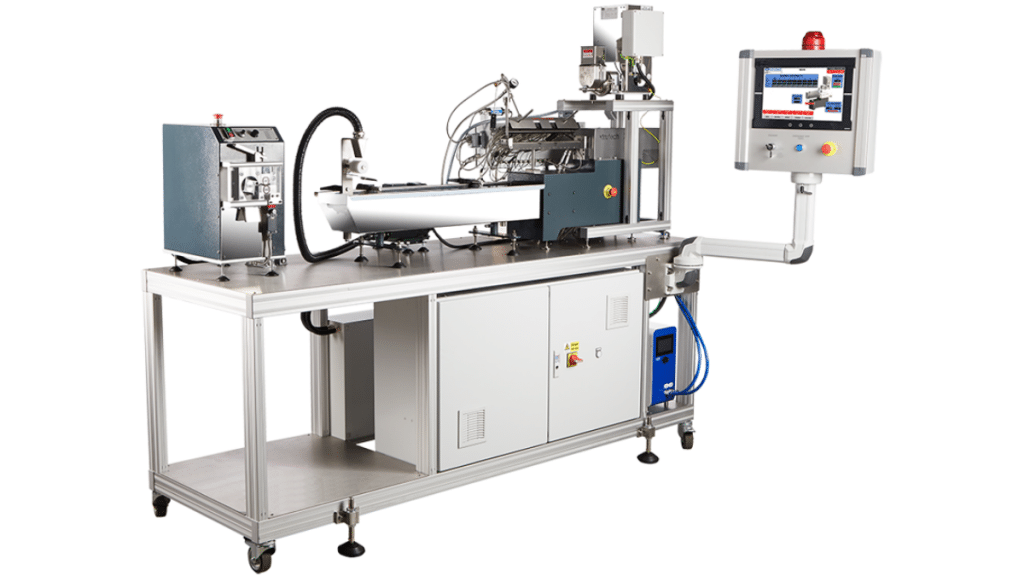

Extruders for Medical Tubing

At the heart of any tubing production process is the extruder, which melts and pushes the raw plastic material through the die. For medical applications, high-performance single screw extruders are commonly used. These extruders are designed for precision, offering tight control over material flow, temperature, and pressure, ensuring the tubing’s dimensional accuracy. Single screw extruders are typically preferred for producing consistent, high-quality tubes with smooth inner and outer surfaces.

For more complex tubing, such as multi-layer or multi-lumen structures, co-extrusion equipment may be necessary. Co-extruders allow multiple materials to be extruded simultaneously, creating multi-layered tubes that offer enhanced performance characteristics, such as improved flexibility or chemical resistance.

Die Heads and Tooling

The die head is one of the most important components of medical tubing extrusion equipment. It shapes the molten plastic into a tube and determines the tube’s dimensions, including its internal diameter, wall thickness, and outer diameter. Medical die heads are designed with extreme precision, often with multiple layers of tooling to allow to produce multi-lumen tubing. These die heads must be made of high-quality materials to withstand the high pressures and temperatures of the extrusion process, as well as the stringent cleanliness requirements of medical manufacturing.

Calibration tools are also critical during the extrusion process, ensuring that the tube retains its desired shape and dimensions as it cools through water or air cooling systems.

With the right equipment in place, manufacturers can produce medical tubing that meets the strict safety and performance requirements needed for life-saving medical applications. By investing in the right extrusion technology, companies can ensure they produce reliable, high-quality medical tubing that plays a vital role in patient care.