Conveyor systems are a lot like the veins of an industrial operation—moving essential materials from one part of a facility to another, seamlessly integrating various processes. In industries from food and beverage to pharmaceuticals, these systems are the unsung heroes that keep things running smoothly.

If you’ve ever wondered about the intricacies behind these systems, this article is your roadmap. We’ll touch on everything from the various types of conveyor belts and flexible screw conveyors to what manufacturers are doing to innovate in this space.

The A to Z of Conveyor Belts: Not Just a “Belt”

When most people hear “conveyor belt,” they picture the flat, moving belt at the airport baggage claim. However, in an industrial setting, conveyor belts come in many forms. From modular and cleated belts to flat and curved variants, the types of conveyor belts are as diverse as their applications. The selection usually depends on the material being moved, the operational environment, and the desired speed and efficiency.

Conveyor Belt Solutions: The Fixer-Uppers

Sometimes, a one-size-fits-all approach doesn’t work, particularly in specialized industries. Conveyor belt solutions are a set of custom modifications and optimizations that cater to specific operational needs.

This can mean integrating sensors for more accurate material tracking or utilizing food-grade belts in a processing plant. The aim is to improve efficiency, reduce downtime, and ensure safety.

The Flexibility of the Flexible Screw Conveyor

Flexible screw conveyors are the ninjas of the conveyor world—they quickly adapt to different tasks. Their spiral design allows versatility, primarily used for conveying bulk materials like powders, granules, and small pellets; they can move materials vertically, horizontally, or at inclined angles, making them an excellent choice for confined spaces and complex routing requirements.

Conveyor Belt Systems vs. Belt Conveyor Systems: What’s in a Name?

This may sound like wordplay, but these terms have a subtle difference. A conveyor belt system refers to the whole setup needed for material movement, including the belt, rollers, framework, and controls.

On the other hand, a belt conveyor system focuses more narrowly on the belt aspect, often a part of a larger conveyor belt system. The terminology can be industry-specific, but it’s essential to know what you’re talking about to get the right system for your needs.

Industrial Conveyor Systems: The Heavy Lifters

Industrial conveyor systems take center stage in heavy-duty environments like mining or construction. These beasts are designed to move large volumes of heavy material over significant distances. Engineered to withstand harsh conditions, they often come with features like robust roller mechanisms and reinforced belts.

The Innovators: Conveyor Systems Manufacturers

Behind every great conveyor system is a team of engineers and visionaries—conveyor systems manufacturers. These folks continuously research and develop new technologies to improve efficiency, durability, and customization. From innovative conveyor technologies that integrate IoT sensors to modular systems that can be easily reconfigured, these manufacturers push the boundaries of what’s possible.

The Road Ahead: Conveyor Technologies and Future Innovations

The conveyor industry is not static; it’s continuously evolving. Advancements in automation, robotics, and IoT drive the next generation of conveyor technologies. Future systems will likely be more adaptive and capable of real-time adjustments to optimize speed, reduce energy consumption, and anticipate maintenance needs.

Where To Turn For Cutting-Edge Conveyor Solutions

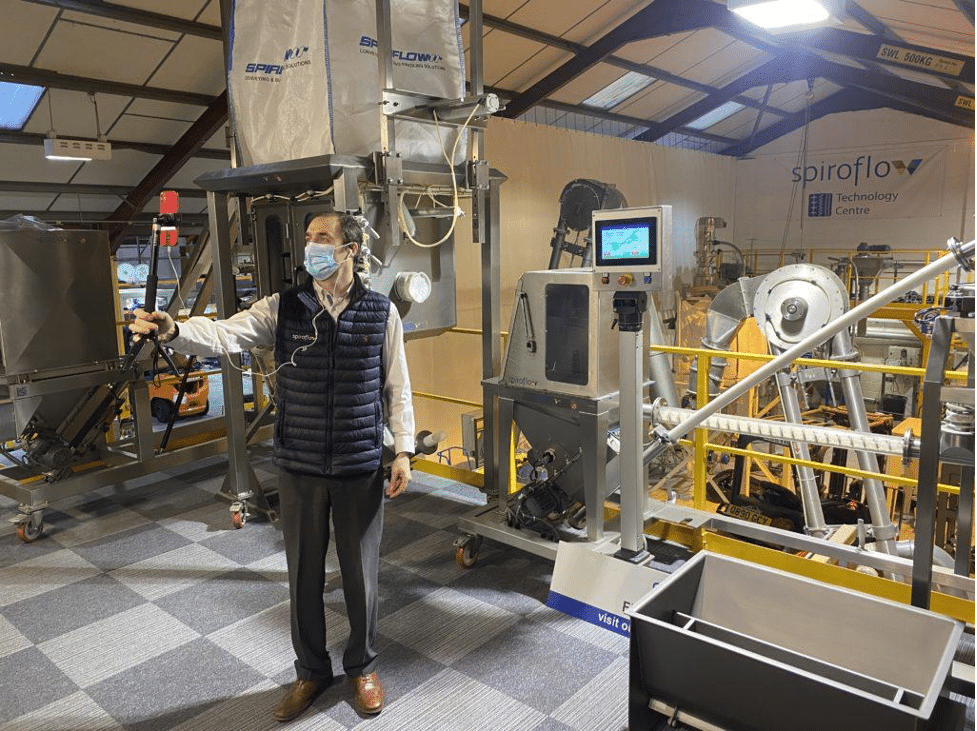

Looking to upgrade or invest in a new conveyor system? Partner with a manufacturer that’s ahead of the curve. With its extensive history and focus on innovation, Spiroflow is the go-to for modern conveyor solutions.

Whether you need a flexible screw conveyor for your food processing plant or a custom belt conveyor system for your manufacturing line, Spiroflow can deliver tailored solutions that meet your specific challenges.

Tomorrow’s Conveyor Systems, Today

As industries advance, the role of conveyor systems grows more complex and integrated. From conveyor belts designed for high-speed sorting to industrial systems that can withstand extreme conditions, the future of conveyor systems is exciting and full of possibilities.

With manufacturers like Spiroflow leading the way in innovative solutions, there’s never been a better time to explore what conveyor systems can do for your operations.