A $30 oil pad heater could save your engine from getting pricey repairs in sub-zero temperatures. But troubleshooting these vital devices becomes significant to protect your vehicle’s health when they stop working properly.

These heaters warm your engine’s oil to optimal temperatures and prevent excessive wear during cold starts. The heating elements or thermostats can sometimes fail. This detailed guide will help you identify and fix common oil heater problems that affect both standard oil pan pad heaters and sophisticated silicone pad systems running at temperatures up to 300°F.

Common Oil Pad Heater Problems

Oil pad heaters face several problems that can affect how well they work. Learning about these common issues helps you fix them quickly.

The biggest problem comes from uneven heat distribution. This usually happens when someone installs the heater wrong or the heating pad doesn’t touch the oil pan surface properly. The resistance wire can also cause temperature differences, especially when the wire’s hardness varies or it’s wound too tight .

Too much heat is another serious problem. Users say their pads can get as hot as 245°F before the thermostat kicks in, then cool down to 170°F before starting up again . Some models need dimmer switches to keep them from melting themselves .

The heaters often have trouble sticking to surfaces, especially in very cold weather. Even the best adhesive pads struggle to stay attached when temperatures drop to

-20°F . Bad adhesion makes the heater less efficient and can be dangerous.

Thermostats break down a lot too. They normally turn on and off about four times every hour and last around 2-3 years or 100,000 cycles . When they fail, the heater either stops working or keeps heating without control.

The heater’s performance can suffer from flow problems and air pockets. These issues usually happen because of: Wrong installation angles

Heater facing the wrong way

Air left in the system

Closed isolation valves

Bad coolant conditions hurt how well the heater works. Scale deposits from hard water or too much antifreeze can make heating less effective . On top of that, too many coolant additives can create a gel that reduces heat transfer.

Electrical problems happen often too. GFI trips are common when moisture from rain, snow, or pressure washing gets in . These safety shutoffs protect against electrical dangers but can be annoying when they keep happening.

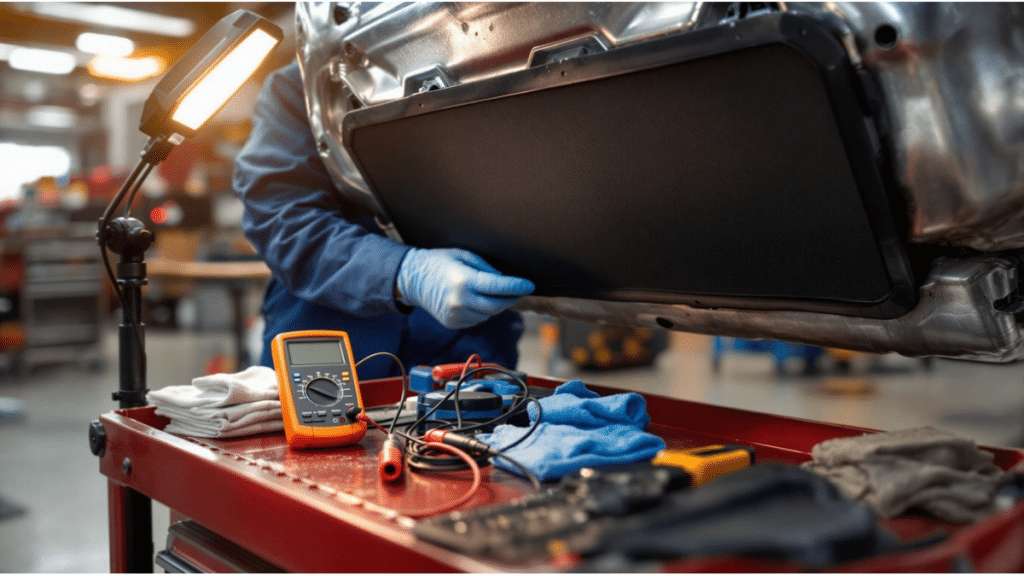

Step-by-Step Diagnostic Guide

Here’s a step-by-step way to diagnose oil pad heater problems. Start by checking resistance with a multimeter set to measure ohms. You’ll need to connect the multimeter leads to both prongs of the AC cord. A proper reading should be between 25 and 8 ohms . Readings below 8 ohms point to a possible short circuit, while anything above 25 ohms means the wattage is too low .

The power supply needs a good look next. Safety comes first – use a grounded outlet and a ground fault type extension cord . Make sure your circuit breaker works properly and the unit gets steady power.

Testing the thermostat? Just disconnect the thermostat wires from T1 and T2 terminals. Bridge the connection with terminal connectors or a piece of short wire. Your thermostat likely needs work if the primary control reads this as a call for heat .

A working oil pad heater should keep oil at 54°F even when it’s -4°F outside . Here’s how to test if the heating element works:

- Disconnect power completely

- Remove any existing paint from the contact surface

- Clean with alcohol or acetone

- Allow surface to dry completely

- Test element functionality by plugging it in briefly for 2-3 seconds

Good adhesion plays a vital role in heat transfer. You need to scuff the surface with a Scotchbrite pad and clean it really well . Then apply epoxy adhesive along the entire heater length to ensure solid contact with the tank surface.

Safety should be your top priority during diagnosis. Direct contact with an active heater is dangerous – one user got a bad burn from just a quick touch . Always use proper testing equipment and stick to the manufacturer’s guidelines.

The adhesives need proper curing at 75°F . After diagnosis, watch the heater’s performance closely when you first turn it on to make sure it works right and regulates temperature properly.

Safety Checks During Troubleshooting

Safety must be your top priority while fixing oil pad heater problems. Taking the right precautions will prevent accidents and help you diagnose issues correctly. Power sources need to be disconnected before you start any inspection. This might seem obvious, but even brief contact with a live heater can result in severe burns

Let the unit cool down completely before you handle it.

Your electrical safety depends on using Ground Fault Circuit Interrupter (GFI) outlets exclusively. If you notice GFI trips, fix the root cause right away instead of plugging into a standard outlet . Check all power cords carefully for wear or damage.

The heater needs proper clearance around it to work at its best. Good airflow will prevent overheating . Keep the unit away from corrosive or combustible materials that could damage it or create unsafe conditions.

Temperature controls need regular monitoring. The thermostat should keep oil temperatures between 120°F and 165°F . Systems with thermostatic protection need testing to make sure they prevent oil from carbonizing.

Check the quality of adhesion often. Poor adhesion cuts heating efficiency and creates safety risks. Your heater must make 100% contact with the mounting surface because air pockets can cause early failure .

Moisture protection needs special care. Keep the heater away from high-moisture areas unless it’s built for humid environments . This means protecting it from rain, snow, and pressure washing.

Regular inspections should cover:

Heating elements for wear signs

Mounting surfaces for proper contact

Temperature control systems

Electrical connections and grounding

Surrounding insulation integrity

Document all maintenance work and fix any unusual sounds, smells, or behaviors that might signal problems . These safety measures will help your oil pad heater system last longer and work better.

Conclusion

Oil pad heaters protect engines effectively, but they work best when properly maintained and troubleshooted. These devices can have problems like uneven heating distribution or thermostat malfunctions. A systematic approach to diagnosis and careful safety protocols make most issues manageable.

Your oil pad heater needs regular checks to avoid engine damage that can get pricey and to give you reliable starts in cold weather. The heater’s performance substantially depends on proper installation, especially when you have surface preparation and adhesive application. Your heater will last longer if you monitor temperature controls and keep electrical connections clean.

Safety must come first during troubleshooting. The diagnostic steps and consistent safety measures will protect your engine and heating system. These devices may look simple, but their proper operation determines whether you’ll have smooth winter starts or expensive repairs.