Insulation materials are as critical as the conductors they insulate in the presence of factors of electrical and electronic engineering in the world. Ordinary materials used as insulations on wires are sometimes insufficient to withstand the extreme working conditions in some systems, such as in the aerospace industry, automotive industry, medical fields and oil and gas. So, this is where PEEK wire has come to the rescue as a game changer solution.

A high-performance thermoplastic recognised by its exceptional thermal stability, mechanical strength, chemical resistance and electrical insulation is PEEK. As a wire coating or insulation coating it guarantees reliability in some of the severe conditions on earth- and even off earth.

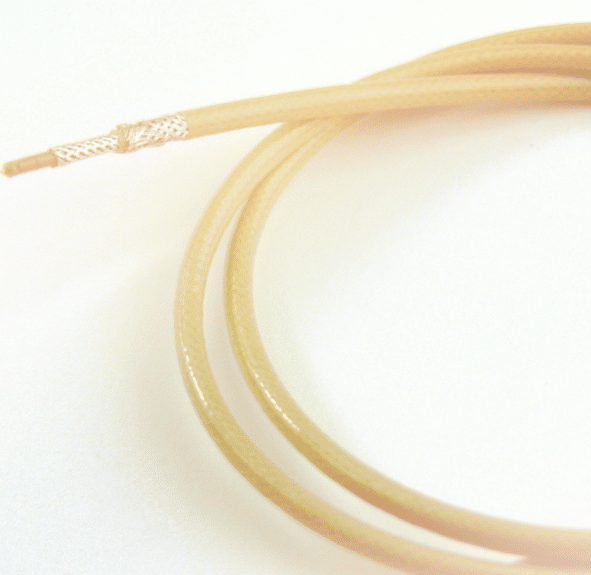

What is PEEK Wire?

Polymers that are used to insulate a conventional wire like PVC, polyethylene, or PTFE cannot withstand temperatures as high as PEEK insulation and they are able to be degraded by fuels and oils or radiation. This is why the PEEK wire is particularly useful in an industry where neither the performance nor the safety should be jeopardized.

PEEK Wire Key Properties

PEEK wire insulation has a combination of properties not seen in any conventional material and is therefore an ideal alternative.

1. Resistance to High Temperatures

PEEK wire can be used continuously in an operating temperature range to 250C (482F) without any tendency to soften or to fall in insulation effectiveness. It also retains mechanical integrity at high rates of temperature cycling, which is important in aerospace and automotive related applications.

2. Mechanical Strength and Durability

The tensile and flexural strength of the polymer does not allow cracking, abrasion or deformation of the insulation, regardless of vibration, or mechanical strains. This makes sure the wire is dependable in transferring systems or places exposed to friction.

3. Electrical Insulation

PEEK has superior dielectric properties, having high resistance to electrical tracking as well as high breakdown voltage. It offers consistent insulation over a broad range of frequencies and it is thus applicable in both high-voltage and high-frequency devices.

4. Chemical Resistance

PEEK wire resists fuel, hydraulic fluids, acids, bases, bases, and organic solvents and the resistant oil PEEK has been utilized in chemical settings with challenging situations. This gives the assurance that insulation does not swell, degrade and lose performance when exposed to industrial chemicals.

5. Flame and Smoke Resistance

PEEK has a natural flame retardance and has low smoke and toxic gas emissions on burn. Such a property is especially beneficial in aerospace, transportation, and medical circumstances in which safety is the primary concern.

6. Tolerance to Radiation and Sterilization

PEEK insulation can resist substantial amounts of radiation without large loss of its properties. It thus complies with sterilization processes such as autoclaving and gamma radiation, hence it is applicable in medical instruments and equipment in hospitals.

PEEK Wire Types

PEEK wire, depending on the application requirement comes in a variety of forms:

- Standard PEEK Insulated Wire: General high- performance electrical applications.

- Thin-Wall PEEK Wire: Applications in aerospace, electronics where weight considerations sometimes are vitally important.

- Multi-Layer PEEK Wire: Greatly gives the wire more protection in extreme conditions (see combination PEEK + other protective insulating materials).

Biocompatible PEEK-Designable versions, sterilizable, surgical tools, medical devices, and implants.

Advantages & Drawbacks Over Traditional Wire Insulation

PEEK wire can outperform PVC, polyethylene, and other typical insulation materials, in heat resistance, chemical resistance, and strength by far. PEEK is even superior to PTFE, used extensively in aerospace and medical applications due to wear resistance, greater load bearing ability and an overall lower weight as compared to many substitutes.

This feature saves maintenance costs, minimizes failure of the systems and enables engineers to come up with smaller systems that are less prone to failure.

Difficulties and thoughts Isabel showed a lot of changes throughout her life. This is because even as a child, she went through a lot of changes. The thing is that there are certain challenges that she also faced. There were also considerations which emerged when she was much younger in life.

The high cost of PEEK wire is its main problem. PEEK is much more costly than the customary insulation materials, and prohibits its application to high-value, or mission-critical systems.

The other aspect is complexity of manufacturing. PEEK Extrusion of and coating of wires with PEEK demands unique equipment taking into consideration high-temperature processing with close tolerances.

Although these factors exist, the positive attributes of the long service life that are difficult to match by other systems, and the short collection of down time generated by the system alongside the increased safety levels often justify the initial costs, particularly in environments where system malfunction is not allowed.

Final Words

During the next number of years, the application of PEEK wire is predicted to expand by far since the aerospace industry, the electric vehicle sector, and the renewable energy business are developed and the medical technology industry is promoted. As the industries shift to smaller, more effective, and longer lasting systems, there is only more demand for high performance insulation.

Future development might feature hybrid insulations systems, PEEK topping off conductive fillers in the system to add shielding capabilities, or nano-enabling the coatings to push the dielectric strength and flame resistance even higher. These innovations may increase the rollover of PEEK wire in the next-generation electronic and robotics technology and even space applications.

BWPEEK is a leading Chinese manufacturer specializing in PEEK cable production. Our product range includes PEEK enameled wires, e-cigarette PEEK temperature-sensing wires, ultra-fine PEEK wires, radiation-resistant and crack-proof PEEK cables for nuclear power plants, LSZH (Low Smoke Zero Halogen) PEEK cables for locomotives, PEEK shielded sheath cables, multi-core PEEK shielded cables, and high-temperature ultra-light PEEK fiber optic cables. Serving diverse industries from high-speed rail to nuclear power, and clients like Xiaomi New Energy and telecommunications companies, BWPEEK has earned widespread acclaim for quality and reliability. For premium PEEK cables, visiting our website: https://peekmaterials.com/peek-forms/peek-wire/