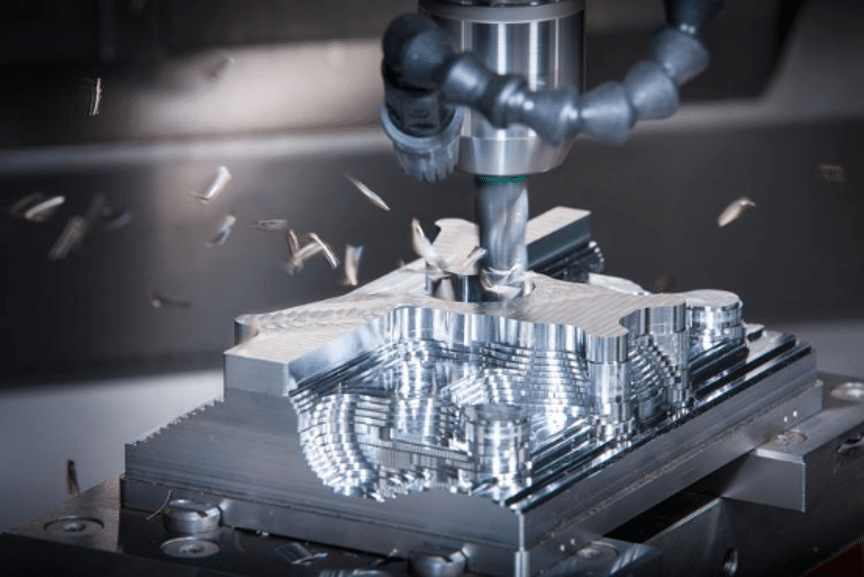

In the fast-paced world of modern manufacturing, precision is everything. From aerospace turbine blades to life-saving medical implants, CNC machining delivers parts with tolerances so tight they’re measured in microns. But achieving this level of accuracy isn’t easy—traditional methods often struggle with tool wear, material inconsistencies, and human error. Enter AI-driven toolpath algorithms, a game-changer that’s redefining precision CNC machining in 2025. By blending cutting-edge artificial intelligence with tried-and-true CNC processes, manufacturers are hitting tolerances previously thought impossible, all while boosting efficiency and cutting costs. This article dives into how AI is transforming CNC machining, why it matters, and what it means for industries like aerospace, medical, and automotive. Let’s explore the future of precision manufacturing—and why you should care.

The Critical Role of Tolerances in Precision CNC Machining

Precision CNC machining is the backbone of industries where even a fraction of a millimeter can make or break a product. Tolerances—how closely a machined part matches its design specs—are the gold standard of quality. In aerospace, for instance, turbine blades demand tolerances as tight as ±0.005 mm to ensure safety and performance. Medical implants, like hip replacements, require similar precision to guarantee biocompatibility. But hitting these targets is tough. Tool wear can throw off measurements, thermal expansion can warp materials, and even the steadiest hands can introduce errors during manual programming.

Historically, CNC machinists relied on experience and trial-and-error to dial in tolerances. But in 2025, the stakes are higher. Complex geometries, exotic materials like titanium and composites, and shorter lead times are pushing traditional methods to their limits. This is where AI steps in, offering a smarter way to achieve precision without the headaches. By analyzing vast amounts of data in real time, AI-driven systems can anticipate problems and adjust on the fly, making precision machining more reliable than ever.

Table 1: Common Tolerance Requirements Across Industries

| Industry | Component | Tolerance Range | Material | Key Challenge |

| Aerospace | Turbine Blade | ±0.005 mm | Titanium | Thermal distortion |

| Medical | Orthopedic Implant | ±0.01 mm | Cobalt-Chrome | Biocompatibility |

| Automotive | EV Battery Housing | ±0.02 mm | Aluminum | Complex geometry |

| Electronics | Microchip Housing | ±0.002 mm | Silicon | Miniaturization |

| Energy | Wind Turbine Gear | ±0.015 mm | Steel | Large-scale precision |

| Defense | Missile Component | ±0.008 mm | Composites | Material variability |

Source: Compiled from 2024-2025 industry reports by Technavio and Modern Machine Shop.

How AI-Driven Toolpath Algorithms Work

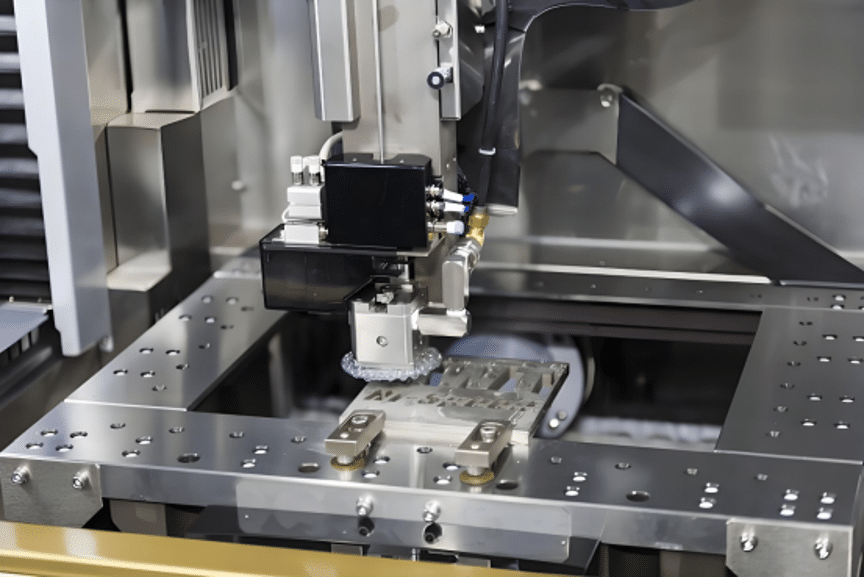

So, what exactly are AI-driven toolpath algorithms? Think of a toolpath as the GPS for a CNC machine, guiding the cutting tool through precise movements to shape a part. Traditional toolpaths are programmed manually or with computer-aided manufacturing (CAM) software, but they often rely on static assumptions about tools and materials. AI changes the game by making these toolpaths dynamic and adaptive.

Using machine learning, AI analyzes data from sensors embedded in CNC machines—vibration, temperature, spindle speed, you name it. It then predicts how these factors will affect the machining process and adjusts the toolpath in real time. For example, if a tool starts to wear, AI can tweak the feed rate to maintain precision. Generative design tools, like Autodesk’s PowerMill, even create optimized toolpaths from scratch, minimizing unnecessary movements and reducing machining time. The result? Parts that hit tolerances with uncanny accuracy, even under tough conditions.

This isn’t sci-fi—it’s happening now. In 2025, AI platforms like Siemens NX and Mastercam integrate real-time feedback loops, allowing machines to “think” as they cut. It’s like giving your CNC machine a brain, and the results are nothing short of revolutionary.

Achieving Sub-Micron Precision with AI

The holy grail of CNC machining is sub-micron precision—tolerances below one micrometer. It’s the kind of accuracy needed for microchip housings or optical lenses. AI-driven toolpath algorithms are making this a reality. By modeling tool wear and material behavior, AI ensures every cut is exactly where it needs to be. A 2025 study by Grand View Research found that AI-powered CNC systems reduced dimensional errors by up to 30% compared to traditional methods, a game-changer for high-precision industries.

Take aerospace, for example. Companies like Boeing use AI to machine composite airframe parts with tolerances of ±0.005 mm, ensuring flawless aerodynamics. In the medical field, AI helps produce implants with surface finishes so precise they reduce patient recovery times. These advancements aren’t just about accuracy—they’re about trust. When a part goes into a jet engine or a human body, there’s no room for error.

Table 2: Impact of AI on CNC Machining Precision

| Metric | Traditional CNC | AI-Driven CNC | Improvement | Industry Impact | Notes |

| Dimensional Error | ±0.02 mm | ±0.005 mm | 75% reduction | Aerospace, Medical | Real-time adjustments |

| Surface Roughness | Ra 0.8 µm | Ra 0.2 µm | 75% smoother | Electronics | Enhanced functionality |

| Tool Wear Rate | 10% per 100 hrs | 7% per 100 hrs | 30% reduction | All industries | Predictive maintenance |

| Scrap Rate | 5% | 2% | 60% reduction | Automotive | Less material waste |

| Tolerance Consistency | 85% | 95% | 10% increase | Defense | Higher reliability |

| Setup Time | 2 hours | 1.2 hours | 40% faster | General Manufacturing | AI-optimized programming |

Source: Data from 2025 reports by MarketsandMarkets and Autodesk.

Boosting Efficiency: AI’s Impact on Cycle Times and Tool Life

Precision is only half the story—efficiency matters just as much. AI-driven toolpaths don’t just make parts more accurate; they make the whole process faster and cheaper. By optimizing tool movements, AI can cut machining time by 15-20%, according to a 2025 Technavio report. For high-mix, low-volume production—like custom medical devices—this is a lifeline, allowing shops to meet tight deadlines without sacrificing quality.

AI also extends tool life, a major cost driver in CNC machining. By predicting wear patterns and adjusting cutting parameters, AI reduces tool degradation by up to 25%. This means fewer tool changes, less downtime, and lower costs. For small shops in the U.S. or U.K., where budgets are tight, this can be the difference between profit and loss. Plus, with AI handling complex materials like superalloys, manufacturers can take on jobs they’d have passed on a decade ago.

Real-World Applications in Aerospace, Medical, and Automotive

Let’s get real: AI-driven CNC machining is already reshaping industries across English-speaking countries. In the U.S., aerospace giants like Lockheed Martin are using AI to machine lightweight composite parts for next-gen fighters, meeting AS9100 standards with ease. The precision ensures parts withstand extreme conditions, from hypersonic speeds to sub-zero temperatures.

In the U.K., medical device manufacturers are leveraging AI to produce orthopedic implants with biocompatible materials like cobalt-chrome. These parts require tolerances of ±0.01 mm to ensure patient safety, and AI delivers every time. The U.K.’s focus on healthcare innovation makes it a hotbed for this tech.

In Canada, the automotive sector is booming, especially for electric vehicles (EVs). AI-driven CNC machines produce battery housings with complex geometries, ensuring thermal efficiency and crash safety. According to a 2025 report by Billor McDowell, Canada’s CNC market is growing at a 7% CAGR, driven by EV demand.

Even smaller shops are getting in on the action. Cloud-based platforms like MakerVerse allow U.S. and Australian manufacturers to access AI-driven CNC services without investing in expensive equipment. It’s precision machining, democratized.

Table 3: AI-Driven CNC Applications by Industry

| Industry | Application | AI Benefit | Tolerance Achieved | Region | Market Growth (2025-2030) |

| Aerospace | Composite Airframe | Reduced errors | ±0.005 mm | U.S. | 8% CAGR |

| Medical | Orthopedic Implant | Surface precision | ±0.01 mm | U.K. | 10% CAGR |

| Automotive | EV Battery Housing | Faster cycle times | ±0.02 mm | Canada | 7% CAGR |

| Electronics | Microchip Housing | Sub-micron accuracy | ±0.002 mm | U.S. | 12% CAGR |

| Energy | Wind Turbine Gear | Material versatility | ±0.015 mm | Australia | 6% CAGR |

| Defense | Missile Component | Consistency | ±0.008 mm | U.S./U.K. | 9% CAGR |

Source: Compiled from 2025 industry data by Grand View Research and MakerVerse.

Overcoming Challenges in AI-CNC Integration

AI isn’t a magic bullet—it comes with challenges. First, there’s the cost. Upgrading to AI-compatible CNC machines or retrofitting older ones can run into the tens of thousands. For small shops, this is a tough sell, though cloud-based solutions are lowering the barrier. Training is another hurdle. Machinists need to learn new software, and programmers must adapt to AI-driven workflows. In the U.S., where 25% of manufacturing workers are over 55, upskilling an aging workforce is no small task.

Then there’s cybersecurity. With CNC machines increasingly connected via IoT, they’re vulnerable to hacks. A 2025 report by MarketsandMarkets notes that 60% of smart factories prioritize secure cloud platforms to protect sensitive designs. Manufacturers must invest in encryption and real-time monitoring to stay safe.

The Future of AI in Precision CNC Machining

Looking ahead, AI’s role in CNC machining is only growing. Digital twins—virtual models of physical machines—are set to revolutionize precision manufacturing. By simulating toolpaths before cutting, digital twins eliminate trial-and-error, ensuring zero-defect production. Cloud-based AI platforms are also making precision machining more accessible, allowing global collaboration in real time.

Sustainability is another frontier. AI-driven toolpaths reduce material waste by up to 60%, aligning with 2025’s push for eco-friendly manufacturing. With the global CNC market projected to hit $128.86 billion by 2026 (Technavio), AI is poised to drive this growth, especially in the U.S., where aerospace and automotive lead the charge.

Why Manufacturers Must Embrace AI-Driven CNC Solutions

The message is clear: AI-driven toolpath algorithms are transforming precision CNC machining. They deliver unmatched accuracy, slash production times, and make complex materials manageable. For manufacturers in English-speaking countries, adopting AI isn’t just a competitive edge—it’s a survival strategy. Whether you’re a small shop in Ohio or a medical manufacturer in London, AI can help you meet the demands of 2025’s high-stakes markets.

FAQ:

1. What are AI-driven toolpath algorithms in CNC machining?

Answer: AI-driven toolpath algorithms are advanced computational instructions that guide CNC machines to cut parts with exceptional precision. Unlike traditional toolpaths, which rely on static programming, AI uses machine learning and real-time data from sensors (e.g., monitoring vibration or tool wear) to dynamically adjust tool movements. This ensures tighter tolerances, reduces errors, and boosts efficiency. For example, platforms like Autodesk PowerMill leverage AI to create toolpaths that cut machining time by up to 20%, according to 2025 industry studies by Technavio.

2. How does AI improve tolerances in precision CNC machining?

Answer: AI enhances tolerances by analyzing real-time data from CNC machines and adjusting toolpaths to account for variables like tool wear, thermal expansion, and material inconsistencies. For instance, AI can maintain tolerances as tight as ±0.005 mm in aerospace components by predicting and correcting deviations during machining. A 2025 Grand View Research study found that AI-driven systems reduce dimensional errors by up to 30%, making them essential for industries like medical and electronics where precision is critical.

3. Which industries benefit most from AI-driven CNC machining?

Answer: Industries requiring ultra-precise components, such as aerospace, medical, automotive, electronics, and defense, see the greatest benefits from AI-driven CNC machining. Aerospace uses AI to machine composite airframes with ±0.005 mm tolerances, while medical manufacturers produce implants with biocompatible materials. In automotive, AI supports EV battery housing production, and electronics relies on it for microchip housings with sub-micron accuracy. Per 2025 Technavio data, these sectors drive global CNC market growth at a 5-10% annual rate.

4. What are the challenges of adopting AI in CNC machining?

Answer: Key challenges include high initial costs ($10,000-$100,000 for AI-compatible machines or retrofits), workforce training needs, and cybersecurity risks in IoT-connected systems. Small shops in the U.S. and U.K. may find upfront costs daunting, while training an aging workforce (25% of U.S. machinists are over 55) is time-intensive. Cybersecurity is critical, with 60% of smart factories prioritizing secure platforms to protect designs, per 2025 MarketsandMarkets reports. Cloud-based solutions help lower these barriers.

5. How does AI in CNC machining contribute to sustainability?

Answer: AI-driven toolpath algorithms reduce material waste by up to 60% through optimized cutting paths and lower energy use by streamlining machining processes. For example, AI adjusts feed rates to minimize power consumption, aligning with 2025’s eco-friendly manufacturing goals. In the U.S., tax incentives from the Inflation Reduction Act encourage sustainable CNC upgrades. This reduces costs and meets growing consumer and regulatory demands for green practices.

6. Can small manufacturers afford AI-driven CNC solutions?

Answer: Yes, small manufacturers can adopt AI-driven CNC solutions through cost-effective options like cloud-based platforms (e.g., MakerVerse), which eliminate the need for expensive hardware. These platforms offer AI-optimized toolpaths for as low as $500-$1,000 per project, per 2025 industry estimates. Retrofitting existing machines is another affordable option, costing 20-30% less than new equipment. These solutions enable small U.S. and Australian shops to compete with larger firms.