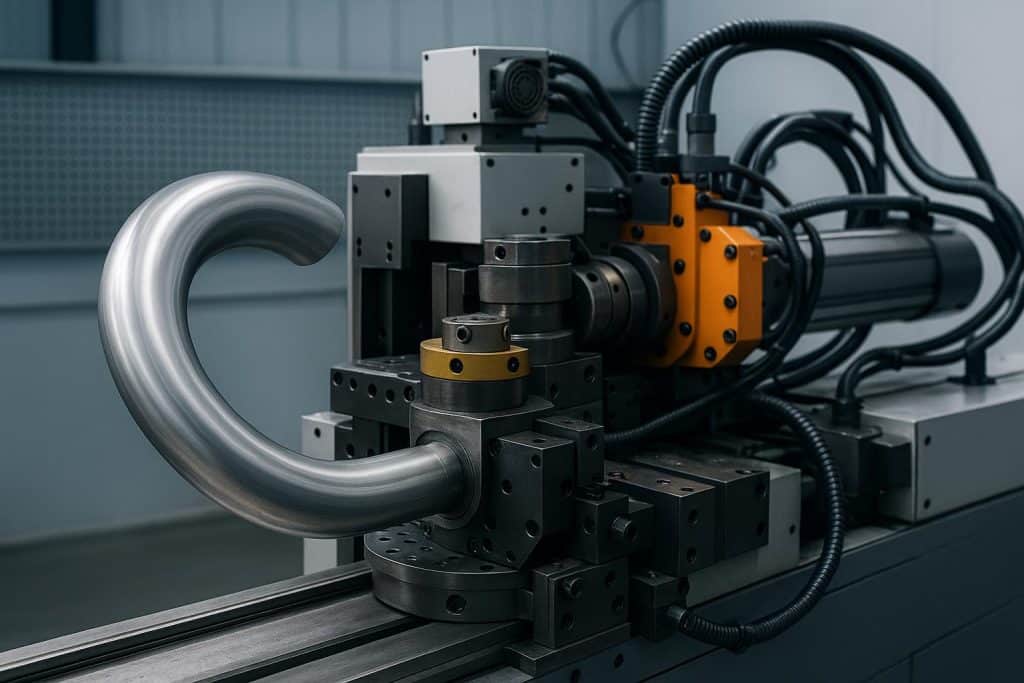

Precision engineering is a cornerstone of modern manufacturing, with the demand for highly accurate parts and components growing continuously. CNC tube bending has emerged as a pivotal technology in meeting these stringent requirements. It provides unparalleled precision in creating complex bends in tubes and pipes, which are essential in countless applications across various industries. Keep reading to gain a deeper understanding of this transformative technology.

Exploring the Advantages of CNC Tube Bending in Precision Engineering

The array of advantages offered by CNC tube bending solutions is what sets them apart in precision engineering. With the ability to execute intricate bending operations, this technology becomes an indispensable tool for engineers looking to push the boundaries of design and functionality. The precision achieved in bends ensures that components fit seamlessly into complex assemblies, reducing the need for additional modifications.

CNC tube bending minimizes human error, ensuring that each bend is consistent with the last, regardless of the production volume. This high level of repeatability is crucial for businesses that rely on uniformity across their parts, such as in the automotive and aerospace industries. The automation of the bending process not only elevates product quality but also contributes to the longevity of the tools and machinery involved.

Customization is another significant benefit associated with CNC tube bending. Given the programmable nature of CNC machinery, engineers can effortlessly adapt the production process to create custom bends to meet specific project requirements. This flexibility makes CNC tube bending a favorite among innovators and design engineers looking to create unique solutions.

The Role of CNC Tube Bending in Enhancing Productivity and Efficiency

One cannot discuss the merits of CNC tube bending without emphasizing its impact on productivity and efficiency within the manufacturing landscape. The automated processes associated with CNC machinery significantly expedite production times, allowing manufacturers to complete tasks that would traditionally take hours in a fraction of the time.

With the integration of CNC tube bending solutions, production cycles are streamlined, and throughput is increased without sacrificing quality. This is particularly beneficial in industries where time-to-market is critical and high-volume production is the norm. It also means that manufacturers can respond more swiftly to market changes and customer demand.

Moreover, the increased efficiency leads to labor cost reductions. Skilled operators are required to program and oversee CNC tube-bending machines, but the number of operators needed per machine is typically less than in manual bending scenarios. As a result, manufacturers can allocate human resources more effectively, dedicating attention to innovation and quality control.

CNC Tube Bending Solutions and Their Impact on Cost-Effectiveness in Manufacturing

The implementation of CNC tube-bending equipment in the manufacturing process can result in significant cost savings. By increasing precision and efficiency, companies see a reduction in material wastage, which translates to lower raw material costs. Additionally, the reduction in manual labor through automation lowers overall labor costs.

Error reductions play a significant role in cost-effectiveness as well. With traditional manual bending, the risks of human error can lead to costly mistakes, requiring rework or scrap. CNC tube bending mitigates these risks by ensuring high accuracy, significantly reducing the incidence of bending errors and the associated costs.

Longer-lasting tools and machinery due to the consistent application of bending forces also mean greater cost efficiency. The wear and tear on equipment is minimized, leading to lower maintenance costs and extended machine lifespans. This stability is crucial for accurate budgeting and financial planning within a manufacturing operation.

The Future of Fabrication: Integrating CNC Tube Bending in Modern Engineering Projects

Looking ahead, CNC tube bending is set to play an even more influential role in the future of fabrication. As materials and design requirements evolve, so will the capabilities of CNC bending machines. We can expect further advancements in control, speed, and versatility, aligning with the industry’s push towards more dynamic and interconnected manufacturing ecosystems.

Smart factories, buoyed by the Internet of Things (IoT) and other digital advancements, stand to benefit from the data-driven nature of CNC tube bending. Real-time monitoring and predictive maintenance will enhance up-time and performance, and the integration of machine learning could even lead to self-optimizing machines that adjust parameters on-the-fly for optimum outcomes.

Overall, CNC tube bending solutions have revolutionized manufacturing, offering an unmatched blend of precision, efficiency, and versatility. As we look to the future of engineering and fabrication, the role of these advanced systems is only set to expand, promising further innovations and improvements in the quality of industrial products.