The Challenge of Heat-Induced Sample Degradation

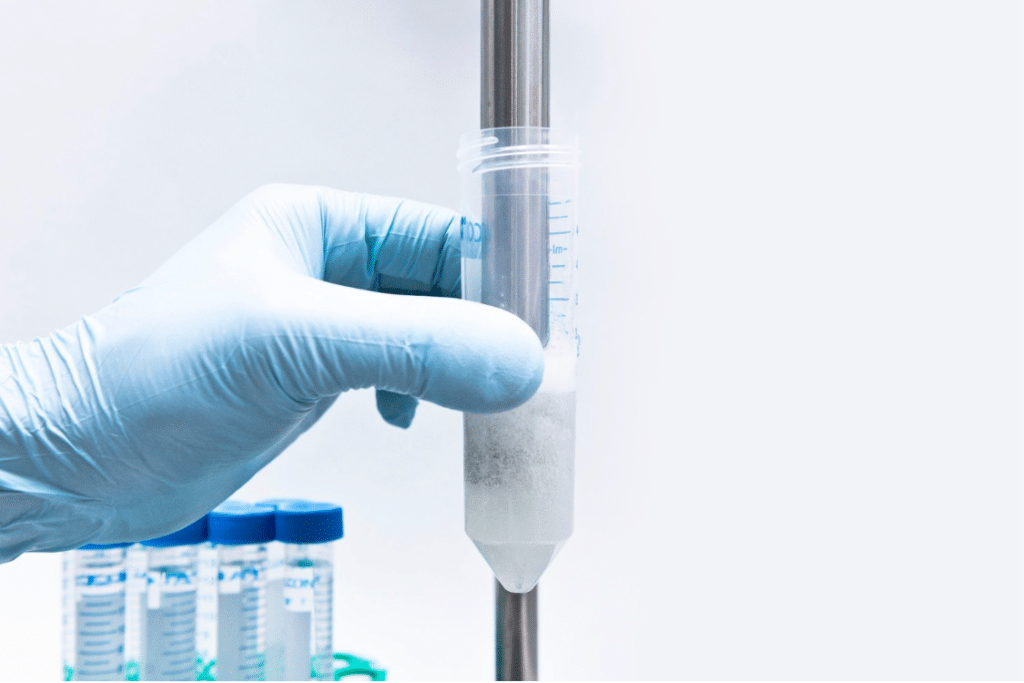

Sample degradation due to excessive heat is a critical concern in laboratory homogenization, where two immiscible liquids are processed into a uniform mixture. Many homogenizers incorporate cooling mechanisms to counteract heat buildup; however, these systems often fail to maintain precise and consistent temperatures, leading to suboptimal sample preservation. Inconsistent cooling can result in sample freezing or overheating, ultimately compromising the integrity of the results.

The Active Cooling Advantage

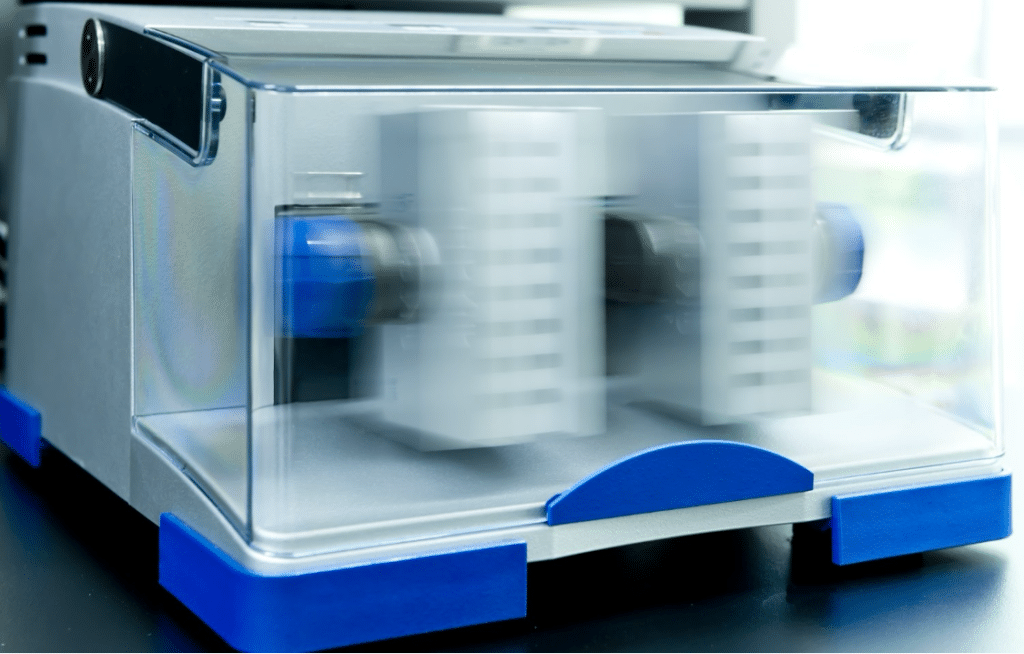

Traditional cooling features in homogenizers often lack precise temperature regulation, making them ineffective in maintaining consistent conditions. The Bullet Blender Gold+ from Next Advance overcomes this limitation by utilizing an active cooling system powered by dry ice or liquid nitrogen. This advanced cooling mechanism ensures that samples remain at the optimal temperature, while integrated sensors continuously monitor conditions and dynamically adjust homogenization energy to prevent temperature fluctuations.

Precision Cooling: Always 4°C, Regardless of Cooling Medium

Unlike conventional homogenizers, the Bullet Blender Gold+ maintains a stable temperature of exactly 4°C, regardless of whether dry ice or liquid nitrogen is used. This precision cooling system not only prevents sample degradation but also enhances the reproducibility of experimental results. By automatically modulating energy output based on real-time temperature readings, the Bullet Blender Gold+ eliminates the risks associated with overheating or inadequate cooling.

Key Benefits of the Bullet Blender Gold+

Laboratories worldwide can benefit from the robust capabilities of the Bullet Blender Gold+, which integrates cutting-edge features to streamline homogenization processes:

- User-Friendly Operation: With an intuitive color touchscreen interface, operating the Bullet Blender Gold+ is as simple as loading up to 24 samples into standard polypropylene tubes and initiating the homogenization process. Unlike other bead mill homogenizers, the Gold+ model does not require a cool-down period between cycles.

- Reproducible Results: Capable of processing up to 24 tissue or cell culture samples simultaneously, the Bullet Blender Gold+ delivers highly reproducible outcomes within minutes. The patented striking technology oscillates samples at over 100Hz (exceeding 6000 cycles per minute), ensuring uniform homogenization at a consistent 4°C.

- Pre-Optimized and Customizable Protocols: Equipped with over 100 optimized protocols and the flexibility to create custom settings, the Bullet Blender Gold+ accommodates a broad range of sample types and research needs.

- Reliable Technical Support: Next Advance guarantees the reliability and durability of the Bullet Blender Gold+, providing ongoing technical support to ensure seamless operation.

Beyond the Bullet Blender Gold+, Next Advance also offers specialized solutions, including Bead Lysis kits tailored for specific sample types and PrecisionPak™ kits designed to enhance sample quality and consistency.

Elevating Homogenization Standards

Achieving reliable and efficient homogenization should not be a matter of chance. The Bullet Blender Gold+ sets a new standard by ensuring uniform temperature control, reproducibility, and ease of use. Whether utilizing dry ice or liquid nitrogen, its fully integrated cooling system maintains a precise 4°C, outperforming conventional homogenizers and safeguarding sample integrity. With the Bullet Blender Gold+, laboratories can confidently achieve high-yield, high-quality results with every run.