In modern product development, selecting the right manufacturing process is a foundational strategic decision with profound implications for cost, quality, and time-to-market. An error in this judgment can lead to budget overruns and a product that fails to meet critical targets, while a well-aligned choice can create a decisive competitive advantage.

Among the most established and widely adopted polymer processing technologies, compression molding and injection molding are titans of the industry. Though both use heat and pressure to shape parts, their fundamental mechanics, capabilities, and strategic applications are distinctly different. This guide will deconstruct each process, compare them head-to-head, and provide a clear framework for choosing the optimal path for your project.

Injection Molding: How It Works & Key Strengths

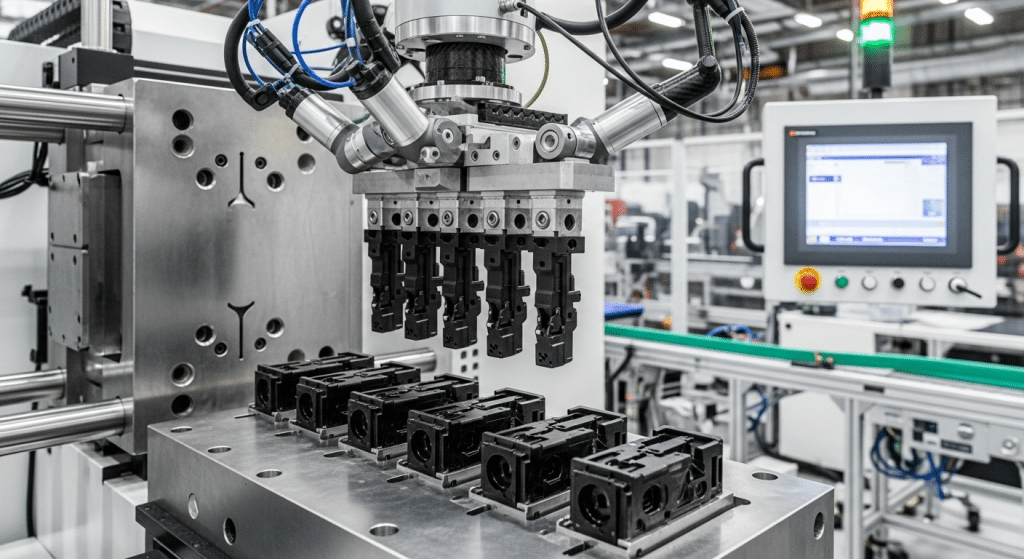

Injection molding is the global standard for the mass production of complex plastic components. The process is defined by its exceptional speed, precision, and high degree of automation.

The cycle begins with plastic granules being fed from a hopper into a heated barrel, where a reciprocating screw melts and homogenizes the material. Once a precise “shot” of molten plastic is ready, the screw acts as a plunger, injecting the material at extremely high pressure (10,000 to 30,000 psi) into a closed, clamped mold. The material fills the mold’s cavities, cools, solidifies, and is then automatically ejected. The entire cycle is incredibly efficient and can often be measured in seconds.

Key Strengths of Injection Molding

- High Speed & Volume: With rapid cycle times, injection molding is the undisputed champion for high-volume mass production, making it the most cost-effective method for parts in the tens of thousands to millions.

- Complex Part Geometry: The immense injection pressure can force material into every minute detail of a mold, allowing for the creation of intricate features like thin walls, sharp corners, and fine ribs with exceptionally tight tolerances.

- High Repeatability: The highly automated and controlled process produces millions of virtually identical parts, which is critical for components in precise assemblies.

What is Compression Molding? How It Works & Key Strengths

Compression molding is a venerable technique renowned for its ability to produce large, high-strength parts from robust thermosetting materials and composites.

The process starts by placing a carefully measured amount of molding material, known as a “charge,” into the lower half of an open, heated mold. The top half of the mold is then closed, and a hydraulic press applies immense pressure (typically 800 to 2000 psi). This force compresses the charge, causing it to flow and fill the mold cavity. The material is held under heat and pressure until it cures into its final, irreversible shape, after which it is removed. While the process is more deliberate, with cycle times measured in minutes, its benefits are substantial for specific applications.

Key Strengths of Compression Molding

- Exceptional Part Strength: Because the material flows a very short distance under low pressure, the finished parts are free from the internal stresses and weld lines common in injection molding, resulting in superior structural integrity.

- Material Compatibility: It is the ideal process for thermosetting plastics (like Epoxy and Phenolic), advanced composites (SMC/BMC), and elastomers (like Silicone and EPDM) that cannot be processed by standard injection molding.

- Lower Tooling Costs: Compression molds are simpler and do not need to withstand high internal pressures, making their construction significantly less expensive. This makes it a financially viable option for prototyping, low-volume, and medium-volume production runs.

Compression Molding vs. Injection Molding: A Head-to-Head Comparison

The optimal choice between these two powerful processes is never absolute but depends on a project’s unique parameters. The following table breaks down the critical differences.

| Attribute | Compression Molding | Injection Molding |

|---|---|---|

| Part Complexity | Best for simple to moderately complex parts; excels with large, flat, or gently curved geometries. | Ideal for highly complex and intricate parts with fine details, ribs, and bosses. |

| Material Compatibility | Primarily thermosets (Epoxy, Phenolic), composites (SMC/BMC), and elastomers (Silicone, EPDM). | Primarily thermoplastics (ABS, PC, PP, Nylon); a vast range is available. |

| Production Volume | Economical for low to medium volumes (prototypes to tens of thousands). | Most cost-effective for high-volume mass production (tens of thousands to millions). |

| Cycle Speed | Slow; cycle times range from 1 to 6+ minutes. | Fast; cycle times range from 2 to 60 seconds. |

| Tooling Cost | Low initial investment; simpler mold construction. | High initial investment; complex molds built to withstand high pressure. |

| Per-Part Cost (at scale) | Higher, due to longer cycle times and more manual labor. | Very low, as tooling costs are amortized over massive volumes. |

| Part Strength | Excellent structural integrity; no internal stresses, flow lines, or knit lines. | High strength, but can have potential weak points at weld lines. |

| Typical Part Size | Well-suited for very large and heavy parts with no theoretical weight limit. | Best for small to medium-sized parts; large parts require very large, expensive machines. |

How to Choose: A Simple Decision-Making Guide

To determine the most suitable process for your project, conduct a thorough internal assessment by answering these critical questions.

- What is your required annual volume? If your projected lifetime volume is under 10,000-20,000 units, the lower tooling cost of compression molding is likely more economical. For mass production in the hundreds of thousands or millions, injection molding’s low per-part cost is unbeatable.

- How large or complex is your part? For large, relatively simple components like automotive body panels or electrical housings, compression molding is ideal. For small, intricate parts with fine details, like electronic connectors or medical device components, injection molding is the only viable option.

- Are you using thermoset or composite materials? If your product requires the high heat resistance and rigidity of a thermoset, the durability of an elastomer, or the superior strength-to-weight ratio of a fiber-reinforced composite, compression molding is the definitive choice. If you plan to use a recyclable thermoplastic, injection molding is the standard.

- What is your primary budget constraint? If minimizing upfront capital investment is the top priority, compression molding’s lower tooling costs present a significant advantage. If the goal is achieving the lowest possible long-term cost-per-part, the high initial investment in an injection mold is justified by the economies of scale.

Conclusion

The choice between compression molding and injection molding is not about finding the “best” process, but the “most suitable” one for your product’s specific goals. Compression molding offers a low-cost entry for strong, robust parts from thermosets and composites, perfect for low-to-medium volumes. Injection molding provides unmatched speed and precision for complex thermoplastic parts at a massive scale.

Making this critical decision correctly requires a manufacturing partner with deep, unbiased expertise in both technologies. As a provider of both state-of-the-art silicone compression molding and precision plastic injection molding, HordRT is uniquely positioned to offer objective, client-centric guidance. Our recommendations are driven by a singular focus: the optimal manufacturing outcome for your project. HordRT can support your entire product lifecycle, from cost-effective prototyping with compression molding to a seamless transition to high-volume injection molding as your demand grows.

Don’t let a complex manufacturing decision become a roadblock. Contact the HordRT engineering team today for a comprehensive process evaluation and consultation.