It is very important to maintain a high level of performance and operation safety in the world of pneumatic systems. Some of these are pressure relief valves, which are very crucial in controlling the pressures within any system to avoid pressing beyond the set limits. With knowledge of the signs that show that the pressure relief valve requires maintenance, instances of possible failure are likely to be overcome, and the life of the system will also be prolonged. In this blog, some signs to indicate that your pressure relief valve needs servicing and the need to always maintain your pneumatic directional control valves will be discussed.

Understanding the Role of Pressure Relief Valves

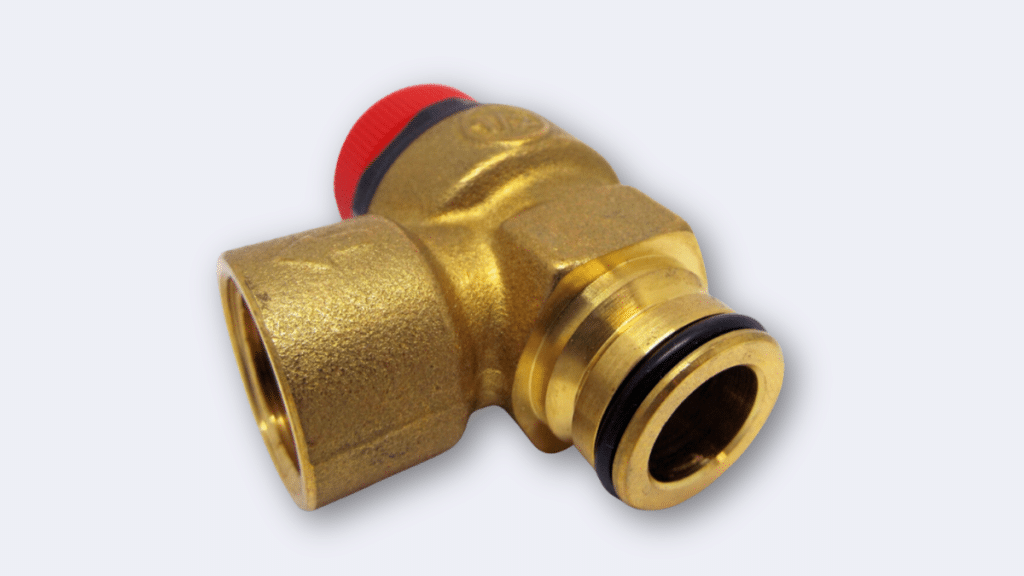

Before analysing the signs suggesting that a valve may need maintenance, it is necessary to discuss the purpose of the pressure relief valve. As the name suggests, this component is meant to relieve excess pressure within the pneumatic system when this rises to a certain level. It does so to avoid wearing off the system parts and to maintain the safety of utilising the pneumatic ways of directional control valves.

Nevertheless, there exists the pressure-reducing valve, which is always misunderstood as the pressure relief valve due to its functions. Although both of them are used in pressure control, the pressure-reducing valve is employed to reduce pressure from a given upstream pressure level to a downstream pressure level that is useful for the subsequent equipment. It is important to understand the difference between these two valves to aid in the operation as well as the maintenance of the relevant system.

How to Recognise that It Is Time for Pressure Relief Valve Repairs

1. Frequent Activation

The first and rather obvious indication that the pressure relief valve needs service is the fact that it’s constantly going off. The valve is opened at specific intervals to discharge pressure, and in such a case, it may be a sign that the set pressure has been set low or there is constant overpressure in the system. They have disclosed that this could be a result of a pressure-reducing valve malfunction or any other complication that requires a technician to look into.

2. Inability to Reset

A pressure relief valve should be able to reopen when the pressure builds up and then close automatically again in case of high pressure. That is why if you observe that after pressure release the valve remains open, it might be due to wear or damage. This may be because of an internal component problem, like a stuck disc or spring, and this is hazardous and needs repair.

3. Unusual Noises

Squeaking, singing, hissing, or whistling are some of the signs in your car that could be a signal showing that your pressure relief valve is off. These sounds also give the impression that air is escaping from the valve, mainly because of worn-out seals or foreign objects stuck within the valve. If these problems are not fixed early enough, then more harm is done to the valves, impairing their ability to function properly as pneumatic directional control valves.

4. Visible Damage or Corrosion

It also indicates visible signs of damage or corrosion of the pressure relief valve during regular inspections of the equipment. Corrosion may compromise the sturdiness of the valve and as a result cause some interactions or failure of the valve. Likewise, any physical harm, which may include the development of cracks or dents, will weaken the strength of the valve. It is noteworthy that the breakdowns and their replacements, if necessary, should be done regularly to ensure the safety of the system and the proper functioning of its components.

5. Inconsistent Pressure Levels

Another indication of a problem with the pneumatic system is if there are abnormal pressure variations and pressures on the system; pressure relief valves, therefore, might not be working as they should. This could probably be due to wear and tear of the individual components or faults in the calibration process. You must always be sure that the valve of the machine is set to the right pressure and that there are no obstructions to the pressure in the system.

6. Valve Leaks

Leakages around the valve are sure indications that a particular piece of equipment needs maintenance. Some of the reasons include seals, gaskets, some inner parts, etc., which may have worn out over time. It is always an essential measure to prevent the loss of pressure in the pneumatic system and the safe working condition of your air systems; that is why as soon as possible, one should address leaks.

The Importance of Regular Maintenance

It is therefore very important to conduct care and regular maintenance of your pressure relief valve for it and your overall pneumatic system. Semiannual visual inspections will address the concern because the necessary repairs can be made before the parts reach the point of needing replacement. This not only helps avoid potential failures but also increases the commercial valve and the corresponding components, including pneumatic directional control valves, and life length.

Furthermore, keeping the pressure relief valve in good condition will enhance efficiency, as it dictates proper pressure in any system. This particular way improves the functionality of your pneumatic directional control valves, making them operate with more efficiency, and not requiring a lot of time to be repaired.

Conclusion

Therefore, it is important to identify some of the most apparent indicators that denote that the pressure relief valve requires maintenance in a pneumatic system. These include a case of use frequency, inability to annul, and any strange sound, any sign of rusting, different pressure, or any leakage of the valve, which are all signs that the valve needs attention. When properly supervised and services, valve failure is unlikely to occur, valve life is greatly increased, and your pneumatic directional control valves will operate at their best. Now you know that regular maintenance is the foundation of a good and risk-free pneumatic system.