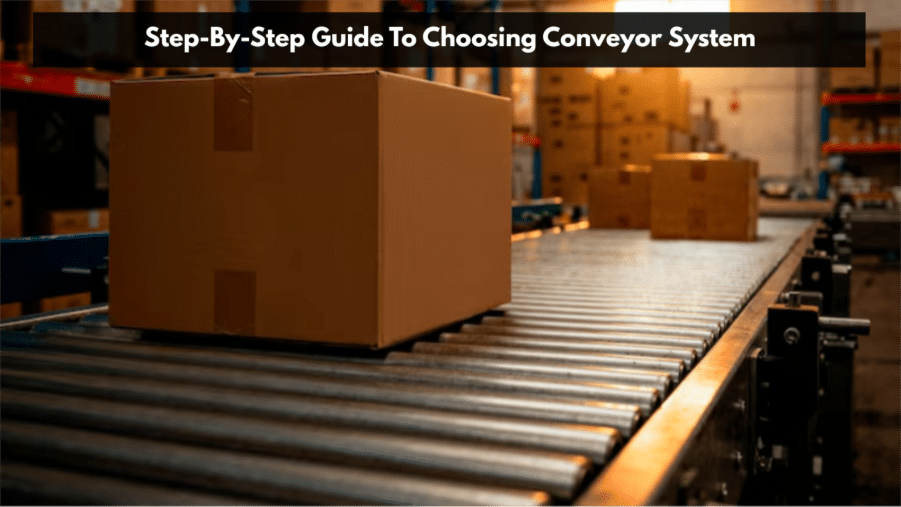

Choosing an appropriate conveyor layout is a critical choice when it comes to an operation that requires the efficient flow of materials. Since conveyors determine the speed of production, uniformity of the workflow, safety, and the long-term cost of operation, selecting the right system requires careful evaluation rather than guesswork.

A systematic process can assist you in knowing what you require, why you require it, and how every component of the conveyor is useful in ensuring a stable performance. When companies take time to specify their material qualities, workflow methods, space constraints, and durability requirements, their choices favor long-term effectiveness.

The following step-by-step guide will give you a clear procedure on how you can evaluate each factor and decide on a conveyor that will enable you to have reliable, safe, and future-proof operations.

1. Understand Material Requirements and Define Role

The first thing is to analyze the physical properties of items that you intend to move. Understanding the weight, size, shape, and fragility of items aids in the specification of the belt width, frame strength, and surface support that your conveyor system needs to offer.

This clarity makes sure you choose a design that ensures that items remain stable during the process of movement and that unnecessary stress is not imposed on the parts. Identifying whether loads are heavy, delicate, irregular, or uniform gives you the basis of all future design decisions.

Once you know what your material needs are, every subsequent decision will be more accurate, efficient, and congruent with the actual operational requirements.

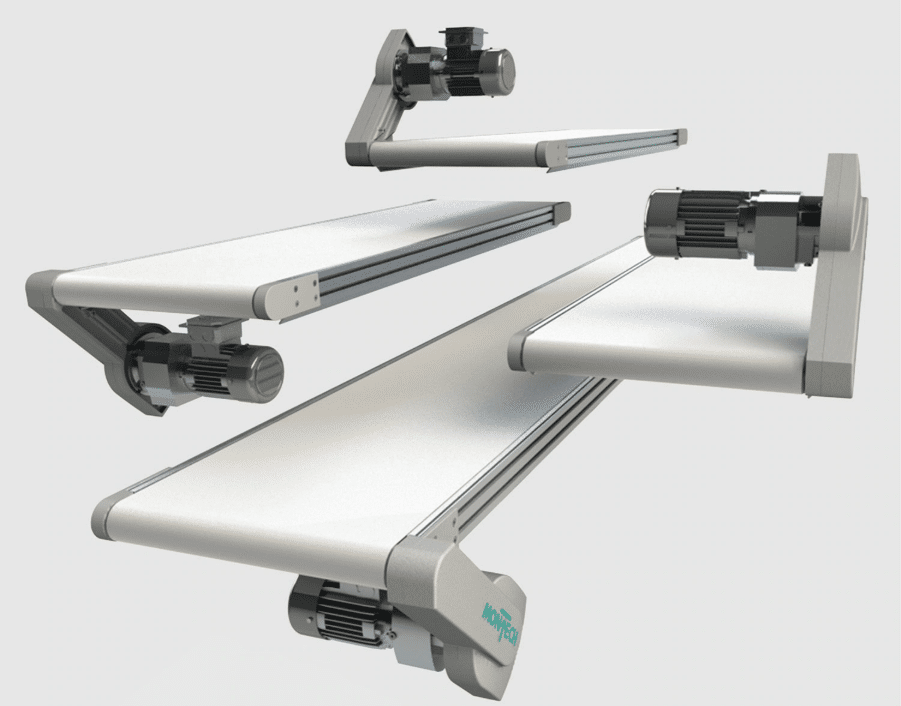

2. Determine Which Conveyor Type Best Fits Your Process

Once you understand your materials needs, look at the types of conveyor that can suit your workflow requirements.

Belt conveyors provide a stable surface and are best suited when handling a lot of different products. Roller conveyors, on the other hand, would suit the heavier or rigid loads that move freely on rollers. While specialty and modular systems serve special purposes, like the accumulation or separation of products.

In determining the type of conveyor, consider the entry, flow, and exit of products into and out of your process. The right decision will be a natural extension of your business process.

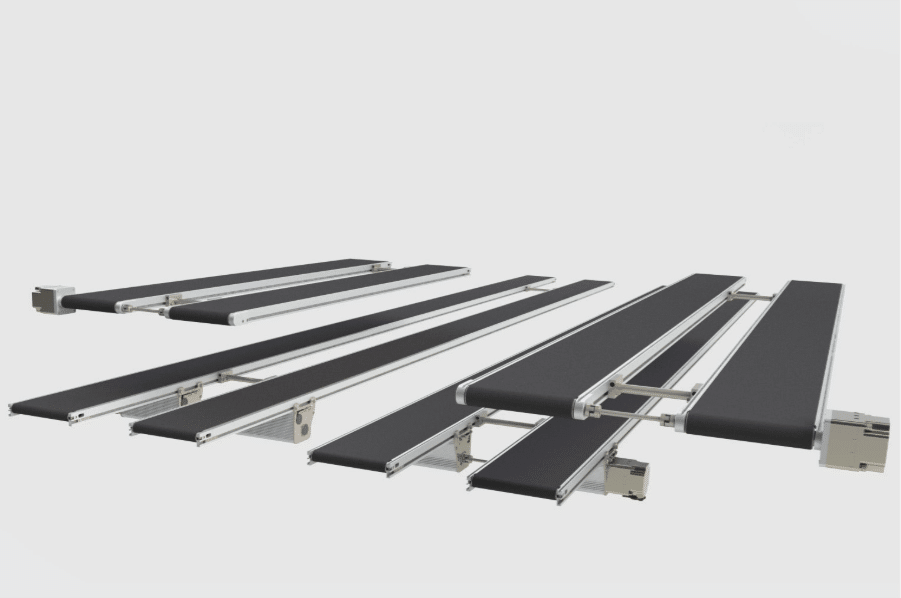

3. Plan Layout, Movement Path, Speed, and Overall Workflow

Layout is the second critical element after knowing the type. You will have to plan the flow of the conveyor in your facility: straight lines or curves, slopes or drops will all impact the design decisions.

Throughput and speed requirements should equal the production targets to ensure that no item slows down without any delay. Space is also a significant factor, as the conveyor must be able to blend with existing equipment and not limit movement.

With the proper layout and workflow planning, you know that the conveyor will help facilitate your operating process and help improve and simplify the operations you perform daily, without complicating them.

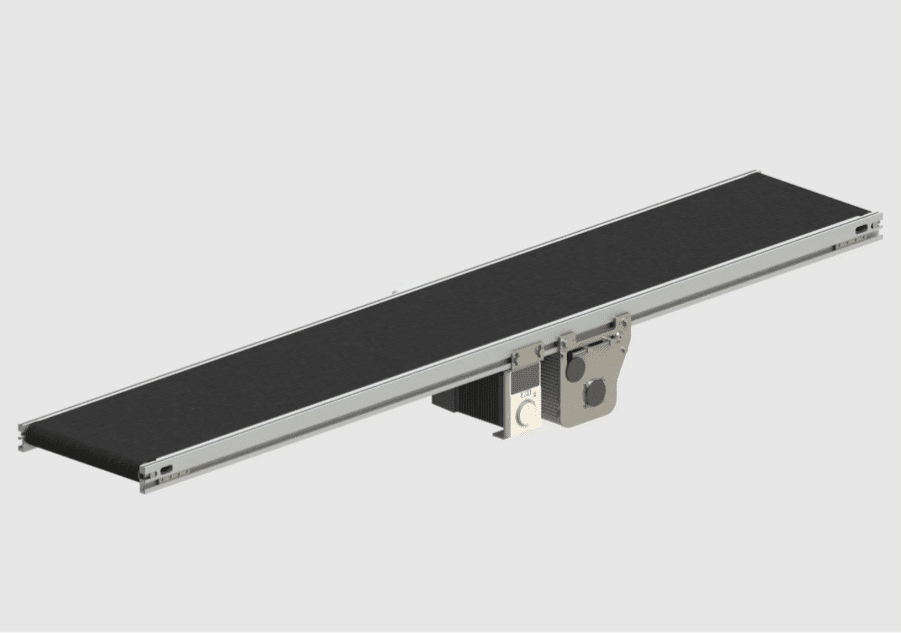

4. Choose Belt Material, Component Quality, and Construction Strength

As your layout is in place, you now focus on the technical specifics that constitute stability and durability. The material of the belt should suit your product and environment, be it flexible, heat-resistant, chemical-resistant, or food-safe sourcing.

In addition, the belt width and texture should hold your things safely, and the frame, rollers, and pulleys should be able to resist everyday wear without the need to be repaired every day.

By choosing materials and components that suit your workflow requirements, you create a conveyor that helps you work every single day.

5. Review Maintenance Needs, Service Access, and Expected Lifespan

Even the most efficient conveyor needs constant maintenance, and therefore, a maintenance factor should affect your choice. Select a system where belts, rollers, and tensioning parts are easily accessible to the user, making servicing a quicker and less disruptive procedure.

Consider the frequency of replacement of parts and the ability of the design to undergo easy new modifications. Durability will also be of concern: tougher material might be more expensive in the short term, but save on repair costs in the long term.

Early knowledge of what to maintain allows you to have your conveyor running without any interruption, and much notice.

6. Evaluate Safety Features and Environmental Requirements

Safety must be central to your decision. Look for features such as emergency stop controls, protective covers, stable guarding, and sensors designed to detect overloads or jams. These elements help protect workers and reduce risk.

Environmental conditions also influence system performance. Temperature extremes, moisture, dust, or chemicals can impact belt integrity and structural reliability. If sanitation is essential, the conveyor should support easy cleaning and meet hygiene requirements.

When safety and environmental compatibility are properly prioritized, you reduce hazards, extend component life, and ensure dependable operation in any setting.

7. Balance Cost, Value, Scalability, and Long-Term Goals

As you finalize your decision, compare the cost against long-term benefits rather than just the initial expense. A reliable system that lasts longer, uses less energy, or requires fewer repairs often offers greater value over time.

Consider whether the conveyor can expand or adapt as your business grows. Modular designs allow adjustments to length, speed, and configuration without full replacement. Evaluating long-term return on investment ensures your conveyor supports current needs while remaining flexible for future demands.

Choosing the system that delivers the strongest combination of durability, performance, and scalability ensures lasting operational value.

Conclusion

The first step towards the appropriate conveyor is the knowledge of your materials, which extends to analysis of type, layout, durability, safety, and long-term worth. A careful approach to every step leads to the creation of a system that facilitates a solid workflow, decreases downtime, and enables the accommodation of evolving operational needs.

Through these steps, you will be sure that you have invested in a system that matches the current operations as well as the future growth and will have a high and steady performance year by year.