Hard coat anodizing, also known as Type III anodizing or hard anodizing, is an electrochemical process that creates a thick, dense, and durable oxide layer on the surface of metal parts. This process offers numerous benefits, including enhanced corrosion protection, increased durability, improved thermal resistance, improved aesthetics, easy maintenance, and more. Let’s explore the advantages of hard coat anodizing and its various applications in different industries.

Corrosion Protection

One of the primary benefits of hard coat anodizing is its exceptional corrosion resistance. The thick oxide layer acts as a barrier between the metal substrate and the surrounding environment, protecting it from moisture, chemicals, and other corrosive elements. This makes hard coat anodizing an ideal choice for metal parts that are exposed to harsh conditions or prone to corrosion.

Increased Durability

The enhanced durability of hard coat anodized parts is another significant advantage. The thick oxide layer provides a hard and wear-resistant surface, making the parts more resistant to scratches, abrasion, and general wear and tear. This increased durability extends the lifespan of the parts, reducing the need for frequent replacements and saving costs in the long run.

Improved Thermal Resistance

Hard coat anodizing also offers improved thermal resistance compared to other surface treatments. The thick oxide layer acts as an insulator, providing better heat dissipation and thermal stability. This makes hard coat anodized parts suitable for applications that involve high temperatures, such as automotive components, industrial machinery, and electronic devices.

Enhanced Aesthetics

In addition to its functional benefits, hard coat anodizing also improves the aesthetics of metal parts. The oxide layer can be dyed in various colors, allowing for customization and creating visually appealing finishes. This makes hard coat anodizing a popular choice for architectural elements, consumer products, and decorative applications where functionality and aesthetics are important.

Easy Maintenance

Hard coat anodized surfaces are easy to clean and maintain. The dense oxide layer is non-porous, preventing dirt, grime, and other contaminants from adhering to the surface. A simple wipe with mild detergent and water is usually sufficient to keep the parts clean and looking new. This ease of maintenance is particularly beneficial in industries where cleanliness and hygiene are crucial, such as food processing, healthcare, and pharmaceuticals.

Applications of Hard Coat Anodizing

Hard coat anodizing finds applications in a wide range of industries due to its exceptional properties and benefits. Let’s explore some of the common applications where hard coat anodizing is extensively used.

Aerospace and Defense

In the aerospace and defense industries, where components are exposed to extreme conditions and demanding environments, hard coat anodizing is widely employed. Hard anodizing for aerospace provides the necessary corrosion resistance, durability, and thermal stability required for critical parts such as aircraft components, military equipment, weapon systems, and more.

Automotive

The automotive industry extensively utilizes hard coat anodizing for various applications. From engine components and suspension parts to decorative trims and wheels, hard coat anodizing enhances the durability and aesthetics of automotive parts. The corrosion resistance and thermal stability offered by hard coat anodizing make it ideal for automotive components exposed to harsh weather conditions and high temperatures.

Electronics

Electronic devices and components often undergo hard coat anodizing to improve their performance and longevity. Hard coat anodized surfaces provide excellent electrical insulation, heat dissipation, and corrosion resistance, making them suitable for electronic enclosures, heat sinks, connectors, and other critical components.

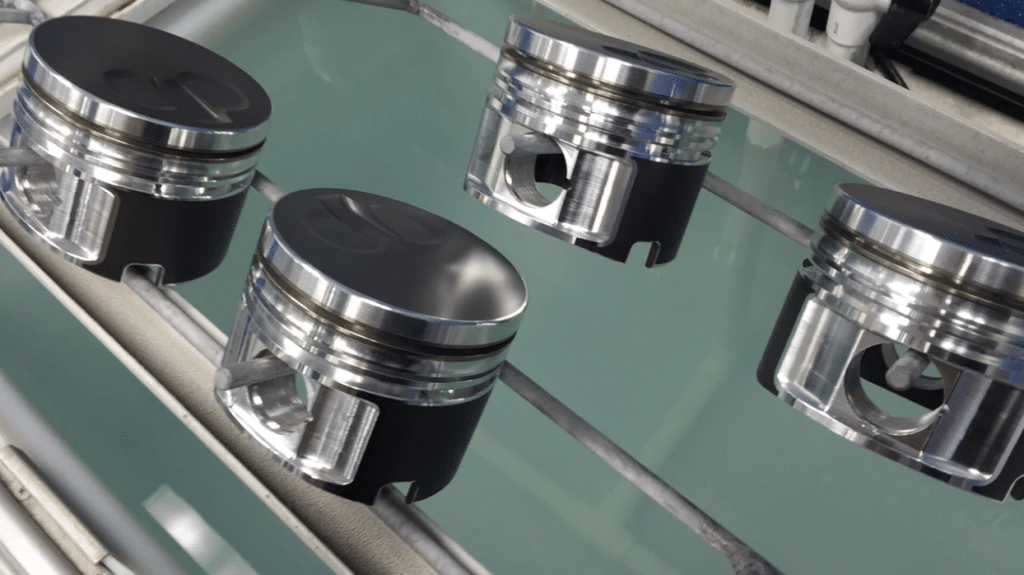

Industrial Machinery

Industrial machinery and equipment subjected to harsh operating conditions can greatly benefit from hard coat anodizing. It enhances the durability and corrosion resistance of components such as gears, pistons, cylinders, and hydraulic systems. Hard coat anodizing also improves the performance of moving parts by reducing friction and wear, resulting in increased efficiency and reduced maintenance requirements.

Consumer Products

Hard coat anodizing is commonly used in the production of consumer products, particularly those exposed to external elements or frequent handling. Items such as handheld devices, sporting goods, kitchen appliances, and outdoor equipment can benefit from the enhanced durability, corrosion resistance, and aesthetic appeal provided by hard coat anodizing. The ability to customize colors and finishes adds a level of appeal to these products.

By choosing hard coat anodizing, industries can ensure that their parts and products withstand the most demanding conditions while maintaining their functionality and visual appeal.