The Anatomy of a Stubborn Clog

Deep within urban wastewater systems, clogs form complex matrices of grease, roots, and debris that resist conventional clearing methods. These obstructions aren’t mere inconveniences—they’re layered adversaries demanding specialized force. Enter the synchronized solution: centrifugal pumps supplying relentless water flow to sewer jetters, transforming hydraulic energy into precision cleaning power. This alliance tackles everything from residential drain backups to municipal line blockages with surgical intensity.

Centrifugal Pumps: The Heartbeat of Hydraulic Force

At the core of this system lies the centrifugal pump, an engineering marvel converting rotational energy into kinetic force. As its impeller spins at 3,500+ RPM, it creates a vacuum that draws water from tanks, accelerating it through volute casings into high-volume streams (typically 30-60 GPM). Unlike positive displacement pumps, centrifugal designs excel in moving large volumes at moderate pressures—making them ideal for sustaining the sewer jetter’s insatiable thirst without pulsations that destabilize jetting nozzles. Key strengths include:

- Adaptability: Handles varying water sources (fresh, recycled, or lightly contaminated)

- Efficiency: Converts 70-80% of motor energy into hydraulic force

- Flow Stability: Maintains consistent supply critical for jetter performance.

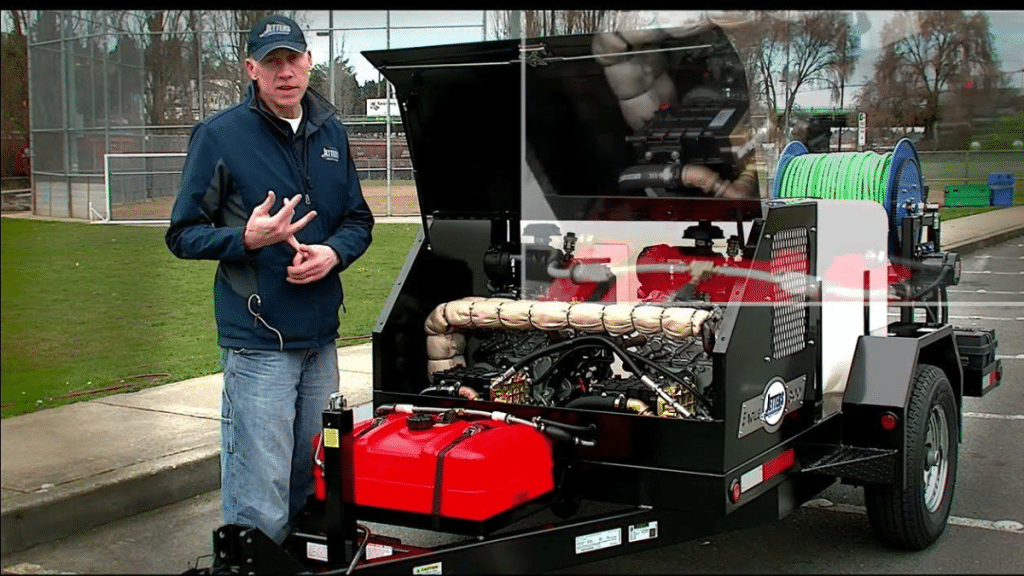

Sewer Jetters: Precision in High-Pressure Form

The sewer jetter acts as the system’s “scalpel,” focusing the pump’s output into penetrating streams. Through dynamically angled nozzles, it transforms water flow into 3,000-4,000 PSI cutting blades that:

- Slice root intrusions with titanium-tipped rotary heads

- Emulsify grease through thermo-chemical reactions

- Propel debris backward for extraction

Specialized nozzles like chain-driven cutters or forward/reverse jets adapt to pipe diameters from 2″ to 36″, proving indispensable in complex networks where mechanical snakes fail.

The Synergy: How Technologies Interlock

The magic unfolds when these systems synchronize:

- The centrifugal pump draws from a 500-gallon tank, delivering 40 GPM at 150 PSI to the jetter’s inlet.

- A triplex intensifier pump within the jetter compresses this flow to 4,000 PSI.

- High-pressure hoses transmit this energy to nozzles, achieving 90-95% cleaning efficiency in concrete mains.

This staged pressure amplification allows centrifugal pumps to work within their efficient range while jetters handle extreme force generation—a division of labor reducing fuel consumption by 25% compared to standalone systems.

Beyond Unclogging: Preventative Ecosystem Maintenance

Modern jetting systems transcend reactive repairs:

- Root Control: Herbicide injection systems prevent regrowth

- Pipe Inspection: Camera ports document line conditions pre/post-cleaning

- Trenchless Prep: Descaling pipes for CIPP lining installations

This transforms sewer jetters from unclogging tools into infrastructure preservation assets, extending pipe lifespan by 15-20 years.

Operational Intelligence: Maximizing Uptime

Maintaining this alliance demands foresight:

- Pump Protection: Stainless steel wear plates shield centrifugal impellers from abrasive particles

- Nozzle Optimization: 0°-40° jet angles selected based on debris type

- Flow Synchronization: Pressure governors match pump output to jetter demand

Proactive maintenance—like monthly seal inspections and annual impeller balancing—prevents 80% of field failures.

The Future: Smart Water Warfare

Emerging innovations are elevating this partnership:

- IoT Sensors: Monitoring pump vibration/jet pressure for real-time adjustments

- Variable-Frequency Drives: Optimizing centrifugal pump speed for changing terrain

- Eco-Formulas: Biodegradable jetting additives enhancing grease dissolution

These advances position the centrifugal pump and sewer jetter as guardians of urban sanitation—proving that against even the toughest clogs, water remains the ultimate solution.