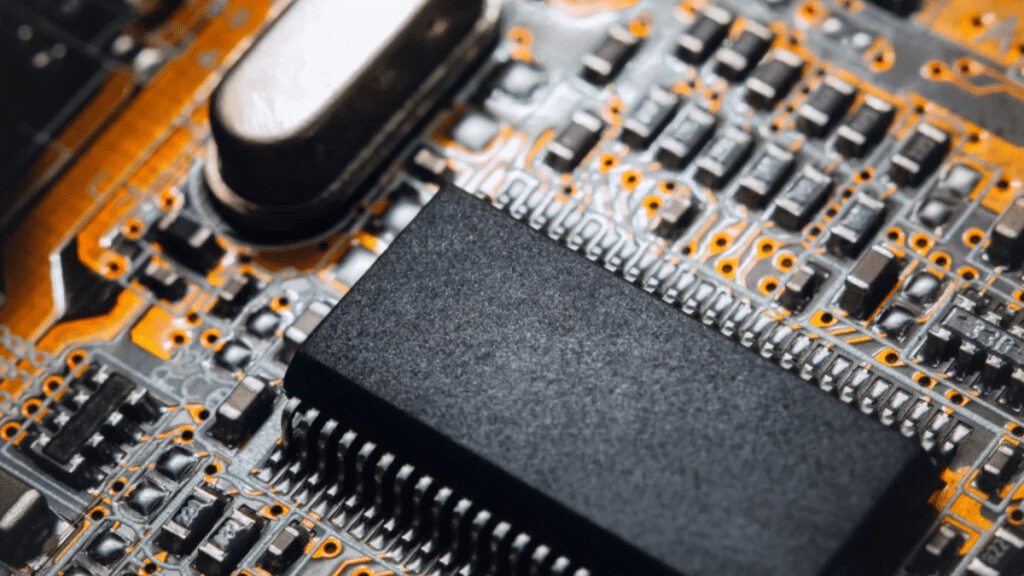

Integrated Circuit (IC) chips are the cornerstone of modern electronics, driving everything from smartphones and computers to medical devices and industrial machinery. While much attention is often given to the design and functionality of these chips, the technology used to package them plays a crucial role in their performance, reliability, and cost. This article delves into the evolution and significance of IC chip packaging technology as part of PCB Manufacturing processes, exploring its advancements, current trends, and future directions.

The Role of IC Chip Packaging

IC chip packaging serves multiple essential functions:

- Protection: Packaging shields the delicate silicon die from physical damage and environmental factors like moisture, dust, and chemicals.

- Electrical Connection: It provides a means to connect the chip to a circuit board or other electronic components through various forms of interconnects.

- Heat Dissipation: Efficient PCB thermal management is crucial to prevent overheating and ensure the chip operates within safe temperature limits.

- Mechanical Support: Packaging helps in mounting the chip onto a printed circuit board (PCB) and maintaining its structural integrity during handling and operation.

Historical Evolution of IC Chip Packaging

1. Early Packages:

- Dual In-line Package (DIP): Introduced in the 1960s, the DIP was one of the earliest packaging methods, featuring two parallel rows of pins. It was straightforward and suitable for through-hole mounting on PCBs.

- Surface-Mount Technology (SMT): The 1980s saw a shift towards SMT, which allowed components to be mounted directly onto the surface of the PCB, enabling higher component density and better performance.

2. Advancements in the 1990s:

- Ball Grid Array (BGA): The BGA package, introduced in the 1990s, featured an array of solder balls on the underside of the package, offering improved performance and thermal management compared to traditional packages.

- Chip-on-Board (COB): COB technology involved directly mounting the chip onto the PCB and wire-bonding it, reducing the package size and enhancing performance.

3. 2000s and Beyond:

- System-in-Package (SiP): SiP technology integrates multiple ICs and passive components into a single package, offering compact solutions for complex systems.

- Flip-Chip Technology: This involves flipping the chip upside down and connecting it to the PCB using solder bumps, enhancing performance and reducing package size.

Current Trends in IC Chip Packaging

1. 3D Packaging:

- Stacked Die Packaging: This approach stacks multiple chips vertically, reducing the footprint and improving performance by shortening interconnect lengths. It’s widely used in high-performance applications like memory modules and processors.

2. Advanced Thermal Management:

- Thermal Interface Materials (TIMs): New materials and techniques are being developed to improve heat dissipation, such as advanced thermal pads and liquid cooling solutions.

3. Miniaturization:

- Leadless Packages: Packages like the Quad Flat No-Lead (QFN) offer a compact form factor without traditional leads, making them suitable for portable and space-constrained applications.

4. Flexible and Printed Electronics:

- Organic Packages: Emerging technologies are exploring the use of organic materials and printed electronics, allowing for flexible and lightweight packaging solutions.

Challenges and Future Directions

Cost and Complexity:

- As IC chips become more advanced, the complexity of their packaging increases, driving up costs. Balancing performance improvements with cost-effective solutions remains a key challenge.

Reliability:

- Ensuring long-term reliability, especially in harsh environments or high-stress applications, requires continuous advancements in materials and manufacturing processes.

Integration with Emerging Technologies:

- The rise of new technologies, such as quantum computing and advanced artificial intelligence, will demand innovative packaging solutions to meet the unique requirements of these systems.

Sustainability:

- There is a growing emphasis on developing environmentally friendly packaging materials and processes to reduce the electronic industry’s ecological footprint.

IC chip packaging technology has come a long way from its early days, evolving to meet the increasing demands of modern electronics. With ongoing advancements in materials, design, and manufacturing, the future of IC chip packaging promises even greater performance, efficiency, and innovation. As technology continues to advance, the role of packaging will remain a critical factor in shaping the future of electronic devices and systems.