In the course of history, twin-screw extruder machines occupy a huge market with their superior characteristics, including better mixing capability, more consistency, improved process flexibility, and better product quality. Due to twin-screw extruder machines’ wide range of applications, they offer a better value that attracts more people to enter the market.

Thus, if you are going to invest in the plastic extrusion machine market, especially for twin-screw extruder machines, this article will help you master all things about them.

Common Types of Twin-Screw Extruder Machines

Plastic extruder machines are being used all around the world. Extruders are generally divided into several main types, and the twin-screw extruder machines are the most popular, consisting of two identical opposite rotating screws in a closed barrel. Furthermore, two common types of twin-screw extruders are:

1. Parallel Twin-Screw Extruder Machine

Parallel twin-screw extruders contain two screws meshed together and rotating in the opposite direction, and the center distance in parallel twin-screw extruders remains the same. Parallel twin-screw extruders have a different shape and size of the screw and barrel compared to conical twin-screw extruder machines.

Besides, the parallel twin-screw extruder is highly specialized equipment for the efficient extrusion of profiles and extrusion pipes of large diameters. The parallel twin-screw extruder has a low shear force. It is used in the filing, blending, re-modification, and engineering of resin.

2. Conical Twin-Screw Extruder Machine

Conical twin-screw extruders have their screws arranged horizontally with the two axes intersected into the barrel at an angle. And the center distance gradually increases from the small end to the large end between the two axes. The conical twin-screw extruder machine has large working torque and a load capacity due to its design, which differentiates it from the parallel twin-screw extruder machine. It is used to produce plastic pipes, plates, profiles, etc.

Benefits of Twin-Screw Extruder Machines

Twin-screw extruders are becoming more and more widely held since they provide many benefits, and some of which involve but are not restricted to:

- Excellent mixing ability and high efficiency, processing several tons of plastic per hour.

- Better and more uniform heat exchange rate from the barrel to the material.

- More versatile machine due to its flexible modular configuration of the barrel and screw.

- High-moisture and sticky materials can be handled in twin-screw extruders.

- With its self-wiping ability, it reduces the risk of residue building up.

- It is also less dependent on the flow properties of the materials.

- Twin-screw extruder machines have a higher capacity and lower power consumption, making them a must-have in a huge range of industries.

All in all, twin-screw extruder machines provide a beneficial experience for the user, which is why they have become popular worldwide.

Applications of Twin-Screw Extruder Machines

Twin-screw extruder machines can be used for creating a variety of products while getting popularized across various industries such as polymer, food, and chemical. At the same time, the products produced by the twin-screw extruder machine are of a large variety like plastics sheets, SPC floors, and many others.

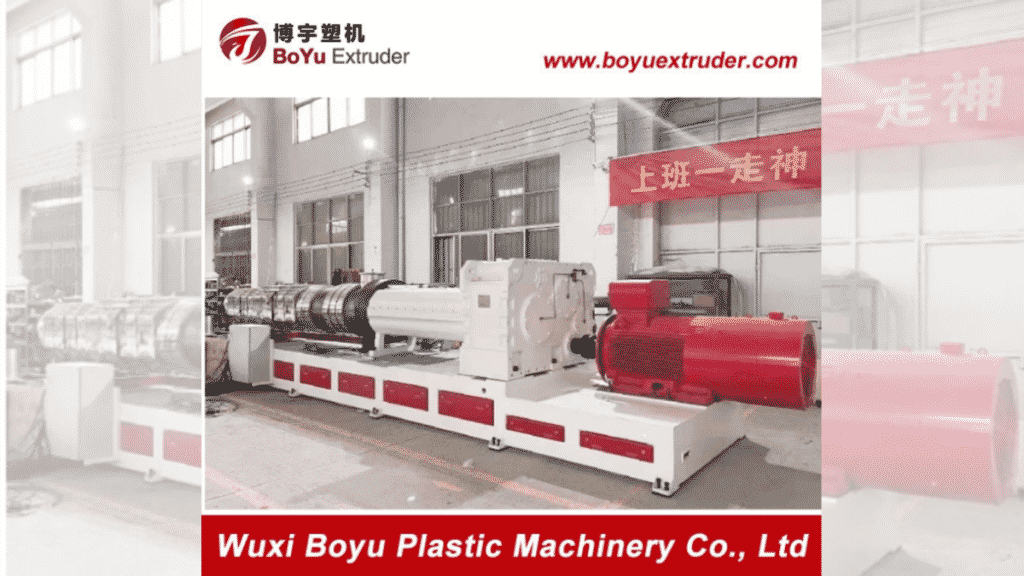

Boyu: a Capable Extrusion Machine Manufacturer

It can be quite difficult to find out which twin-screw extruder machine may be able to satisfy your needs and to find a trustworthy manufacturer whose products can be trusted. Against this backdrop, Boyu is one of the suppliers with more than twenty years of experience in extrusion while producing different extrusion lines such as WPC, PP, SPC, and PVC.

Boyu is one of the most professional, high-quality plastic extrusion machine manufacturers throughout the year. Their products can be guaranteed to be of the highest quality since they have passed multiple quality system certifications and always strive to provide the best for their customers. Other than that, the company has highly qualified experts in research and development that can deal with the latest technology, reliable, safe, and eco-friendly products. Please have a look at the excellent products and solutions offered by the company.