Construction sites are dynamic environments where safety is a top priority. Among the various safety measures implemented, tool tethers play a crucial role in preventing accidents and injuries caused by falling tools. In this blog, we will explore the importance of tool tethers in construction safety, their benefits, and how to effectively implement them on a construction site.

What Are Tool Tethers?

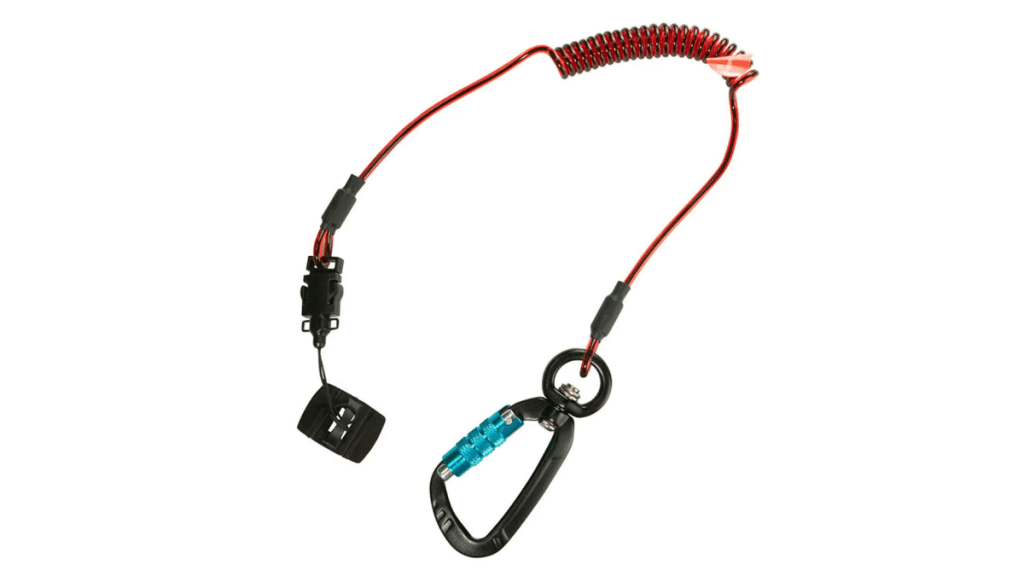

Tool tethers are safety devices designed to secure tools to a worker or a fixed point, preventing them from falling and causing harm. Typically, tool tethers consist of a durable cord or strap with attachment points on both ends. One end is attached to the tool, while the other end is secured to a belt, harness, or a fixed structure. By using tool tethers, workers can ensure that their tools remain within reach and do not pose a hazard to themselves or others on the site.

Key Components of Tool Tethers

- Attachment Points: Securely connect the tether to the tool and anchor point.

- Tether Line: A strong, flexible line designed to withstand significant weight and impact forces.

- Shock Absorbers: Reduce the force exerted on the tether and attachments during a drop.

3 Types of Tool Tethers

There are various types of tool tethers designed to accommodate different tools and work environments.

1. Retractable Tethers

Retractable tethers function similarly to a retractable leash, with a mechanism that allows the tether to extend and retract as needed. These tethers are housed in a compact, retractable casing that keeps the tether neatly stored when not in use.

Ideal For:

- Tools Requiring Frequent Movement: Retractable tethers are perfect for tools that need to be frequently moved or adjusted. The retractable mechanism provides flexibility and ease of use, allowing workers to extend the tether when the tool is in use and retract it when it’s not.

- Clutter Reduction: These tethers help reduce workspace clutter by keeping the tether line out of the way when not extended, thereby minimizing tripping hazards.

2. Coiled Tethers

Coiled tethers are made from coiled cords that stretch when pulled and retract to their original shape when released. This design keeps the tether compact when not in use, but allows it to extend to a considerable length when needed.

Ideal For:

- Tools Used at Various Lengths: These tethers are suitable for tools that need to be used at varying distances. The coiled design allows the tether to extend as far as needed without excess slack.

- Minimizing Slack: The coiled nature prevents excessive slack that could get caught on equipment or create tripping hazards.

3. Fixed-Length Tethers

Fixed-length tethers are simple, non-retractable cords of a predetermined length. These tethers provide a constant length, which can be beneficial for certain tasks and tools that do not require significant movement.

Ideal For:

- Static Tool Use: Fixed-length tethers are suitable for tools that are generally used in a fixed position or do not require extensive movement.

- Consistent Positioning: These tethers are ideal when a consistent, fixed distance is needed between the tool and the anchor point.

The Role of Tool Tethers in Construction Safety

Preventing Injuries

One of the primary reasons for using tool tethers is to prevent injuries caused by falling tools. In a busy construction site, a dropped tool can quickly become a dangerous projectile, posing significant risks to workers below. Tool tethers ensure that even if a tool slips from a worker’s hand, it remains securely attached and does not fall to the ground, thereby reducing the risk of injury.

Protecting Property

Falling tools can cause considerable damage to property and equipment on a construction site. Whether it’s damaging sensitive machinery, breaking materials, or causing structural damage, the consequences can be costly. Tool tethers help mitigate these risks by keeping tools securely attached and preventing falls that could lead to damage.

Enhancing Productivity

By using tool tethers, workers can focus more on their tasks without the constant worry of dropping tools. This increased confidence can enhance productivity, as workers spend less time retrieving fallen tools and more time completing their tasks. Additionally, the reduced risk of accidents means fewer interruptions and downtime on the site.

Compliance with Safety Regulations

Many safety regulations and standards, such as those set by OSHA (Occupational Safety and Health Administration), require the use of tool tethers in certain situations to minimize the risk of falling objects. By implementing tool tethers, construction sites can ensure compliance with these regulations, avoiding potential fines and enhancing overall site safety.

Implementing Tool Tethers on Construction Sites

Assessing the Work Environment

Before implementing tool tethers, it is essential to assess the work environment to identify areas where tools are used at heights or over unprotected areas. Understanding the specific needs and risks of the site will help in selecting the appropriate types of tool tethers.

Selecting the Right Tethers

Choosing the right tool tethers involves considering the type of tools being used, their weight, and the working conditions. It is crucial to select tethers that are rated for the weight of the tools and suitable for the specific tasks being performed.

Training Workers

Safety training programs are essential to ensure that workers understand the importance of using tool tethers and know how to use them correctly. Training should cover attachment techniques, inspection procedures, and the importance of regular maintenance.

Regular Inspections and Maintenance

Tool tethers should be regularly inspected for signs of wear and damage. Any tether showing signs of weakness should be replaced immediately to maintain safety. Regular maintenance checks ensure that all tool tethers remain in good working condition.

Tool tethers are an indispensable part of construction safety, playing a crucial role in preventing injuries, protecting property, and enhancing productivity on the site. By understanding their importance and implementing them effectively, construction sites can create a safer environment for workers and comply with safety regulations. Prioritizing the use of tool tethers demonstrates a commitment to safety and helps maintain a productive and injury-free workplace