CNC stands for computer numerical control, and it is a programmable algorithm that gives machines specific instructions to carry out specific processing duties such as drilling and milling. The code implies the procedure of adding, eliminating or drilling substances based on their required layouts.

A CNC interacts with the machine via a compatible computer and software. Most of the CNC codes are numerical, so the software remakes the input into Cartesian coordinates that gives the device a chance to function in various planes and degrees of freedom. This gives the machines the ability to work with precision making sure they don’t have any errors.

Today CNC machining service is being used across various production companies since it is easier and faster. A CNC machine can modify any given material into a particular product using two specific methods: by additive procedure and subtractive procedure. CNC machining and 3D printers are examples of additive and subtractive CNC operations.

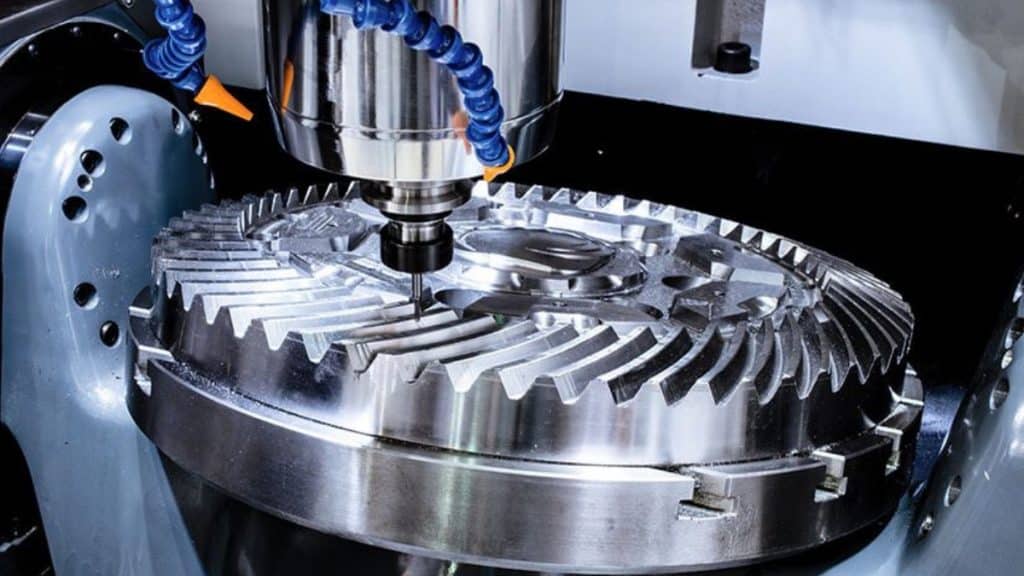

CNC milling parts

Frame

This CNC milling part makes sure the machine is rigid so that it could be able to resist additional cutting force. We can say that this part holds the CNC machine; if not, it wouldn’t carry out its services as well as it should.

Table

The table is where the workpiece is held firmly when the milling procedure occurs. Milling machines use T-slots to attach a device -vice that holds the workpiece, though some parts can be used to carry out the job called fixture plates.

Spindle

The spindle is the essential part of the milling machine, and it has a rotating assembly where the tool holder is attached.

How 3D Printing Works

3D creation usually starts with a model, and you can get these models from the library, or you can come up with your model from scratch.

3D software

There is numerous software equipment you can use. They range from open source to industrial grade. In case you are just beginning, the best equipment to use is Tinkercad since it is available in your browser for free. Tinkercad offers free lessons for beginners, and it also has a printable file that allows you to print your model.

Slicing

Slicing means slicing your model into multiple layers, and you can do this using slicing software, and the file becomes ready for printing immediately after you have cut it. After doing this, you will have to print your file using WI-FI.

How long does it take to print in 3D?

The time taken to print in 3D depends on several things, such as the size and printing setting. You should also make sure your final product is of high quality. The 3D procedure can take a day or weeks, depending on the intensity of your products.

Also, make sure you have a good quality 3D printer that will print out your 3D printing instant quote well.

Conclusion

Companies that use CNC machine services and 3D printers are ahead of companies still using the old methods since work is done quickly and efficiently.