In recent years, household robots have rapidly transitioned from futuristic novelties to commonplace devices in modern homes. From robotic vacuum cleaners and lawn mowers to AI-powered assistants capable of managing home appliances, security, and communication, the domestic robotics market is flourishing. Driven by advancements in artificial intelligence, sensor technologies, and compact electronics, these machines are reshaping the way people interact with their living spaces. However, as with all electronic devices, the growth of household robotics introduces a pressing issue: how to responsibly manage their disposal and end-of-life processing.

The Expansion of Household Robotics

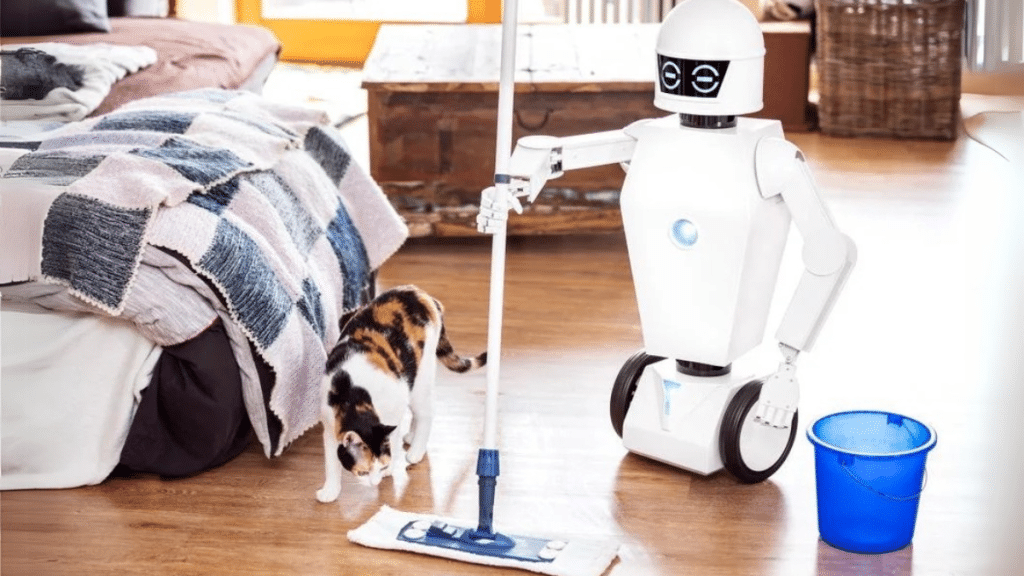

Once limited to industrial applications, robots are now being designed for personal use in homes, supporting everything from cleaning and caregiving to entertainment and surveillance. The popularity of robotic vacuums and mops, in particular, has paved the way for broader acceptance of machines that autonomously perform daily chores. The increasing availability of smart speakers and digital home assistants further supports integration of robots with centralized home systems. With manufacturers constantly releasing upgraded models boasting better navigation, smarter programming, and enhanced connectivity, consumers are increasingly replacing older units, contributing to a growing volume of outdated robotic hardware.

Materials and Components of Concern

Household robots are complex systems that include motors, circuit boards, batteries, sensors, screens, and plastic or metal housings. Many of these components contain valuable and potentially hazardous materials, including rare earth elements, lithium, cadmium, and lead. Batteries in particular pose safety and environmental risks if not properly handled, as they can leak chemicals or even explode under certain conditions. These batteries require proper battery recycling services to ensure they’re handled safely and in an environmentally friendly way. Printed circuit boards contain not only recoverable metals like gold and copper but also flame retardants and other substances that can become harmful if incinerated or left in landfills.

As the production of these devices scales up, so too does the challenge of dealing with the materials embedded in them once they reach obsolescence. Unlike traditional appliances or larger electronics, small robots may be easily overlooked or discarded in regular trash due to their size or perceived complexity of recycling.

Short Product Lifecycles and Accelerated Obsolescence

Rapid technological advancement has resulted in shorter lifespans for household robots. Manufacturers frequently release improved models with enhanced features, such as better AI capabilities, stronger battery life, or integration with newer smart home ecosystems. This encourages consumers to upgrade more frequently, sometimes well before their existing robot reaches the end of its functional life.

The lack of standardized modular design across manufacturers also hinders repairability and component reuse. In many cases, once a battery degrades or a key sensor fails, the entire unit is considered unserviceable and discarded, even if the majority of the components remain functional.

Recycling and Reuse Barriers

One of the central challenges in dealing with end-of-life household robots is the lack of tailored recycling infrastructure. These devices, though technologically complex, do not always fall neatly into existing categories of consumer electronics. As a result, recycling centers may not prioritize disassembly or proper material recovery. Furthermore, the automated nature of these devices often means they contain proprietary software and hardware elements that complicate safe data deletion and part reuse.

Consumers are also often unaware of how to properly dispose of robotic devices. Without clear guidance or accessible recycling drop-off points, users may opt to store broken robots indefinitely or dispose of them improperly.

Design for Sustainability

To counteract these challenges, a shift toward sustainable design in robotics is essential. This includes developing robots with modular components that can be easily repaired or upgraded, using recyclable or biodegradable materials, and reducing reliance on non-renewable or hazardous elements. Incorporating universal parts that work across generations of devices could also extend product lifecycles and reduce electronic waste.

In addition, manufacturers can explore take-back programs and offer incentives for customers to return old devices for safe dismantling or refurbishment. Such initiatives not only promote responsible disposal of electronics, but also reinforce corporate responsibility and consumer trust.

The Path Forward

As household robots become more prevalent, their environmental impact cannot be ignored. While these machines offer undeniable convenience and efficiency in modern homes, they also represent a new frontier in electronic waste management. Addressing the end-of-life concerns of these devices will require coordinated action across manufacturers, regulators, recyclers, and consumers.

Educational outreach to inform the public about responsible disposal, as well as improved infrastructure for robotic recycling, will be necessary to mitigate the consequences of this emerging waste stream. In the long term, fostering a culture of sustainable innovation in the robotics sector—one that balances convenience with environmental stewardship—will be key to ensuring that the benefits of domestic automation do not come at the cost of planetary health.