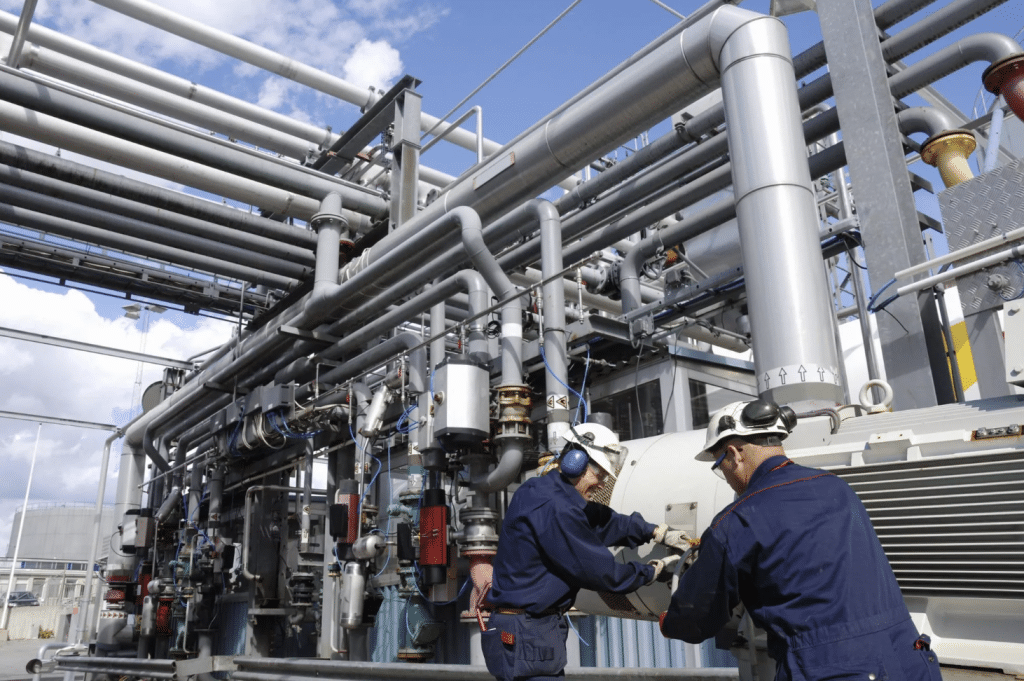

In industrial settings, maintaining compliance with stringent safety regulations is paramount. One often overlooked yet critical element of this compliance is the use of pipe markers. These labels are not just signs; they are essential tools for identifying the contents and direction of flow within pipes, which is vital in preventing accidents and ensuring operational safety.

Across various industries—from chemical plants to manufacturing facilities—regulations governing the marking of pipes are extensive and detailed. Industry standards such as those set by OSHA, ANSI, and ISO establish strict guidelines for labeling pipes to prevent hazards. Properly placed pipe markers help ensure that employees, contractors, and emergency responders can identify the risks involved and take appropriate action.

Meeting Compliance Through Proper Pipe Marking

The critical role of pipe markers in regulatory compliance cannot be overstated. These markers ensure facilities adhere to health, safety, and environmental standards. Marking hazardous materials like chemicals, gases, and steam correctly can avert disastrous consequences. Clear identification through markers helps prevent leaks, fires, and even explosions. Moreover, regulatory bodies mandate strict rules on color coding, size, and placement of pipe markers to avoid confusion and ensure quick readability.

Failure to comply with these regulations could result in fines, penalties, and potential operational shutdowns. Industries must invest in high-quality markers and ensure they are placed and maintained correctly. Beyond compliance, the right markers promote a safe work environment, preventing costly accidents and protecting both personnel and the environment.

Key Benefits of Pipe Markers in Safety and Efficiency

Beyond meeting regulatory standards, pipe markers offer significant operational safety and efficiency benefits. They enable clear and concise identification of hazardous materials and flow direction, reducing the risk of accidents. Workers can quickly locate the pipes they need to address during maintenance or emergencies. This leads to faster, more efficient responses and minimizes downtime in case of equipment failure.

In addition, marked pipes reduce the likelihood of human error. In facilities that manage complex pipeline systems, such as oil refineries and chemical plants, even a moment’s confusion can result in catastrophic mistakes. Thus, investing in durable and well-placed pipe markers reduces risks and enhances operational efficiency.

Choosing the Right Pipe Markers for Your Industry

Selecting the right pipe markers ensures your facility complies with industry standards. Durability, legibility, and visibility are key factors when choosing markers. Industrial settings often present harsh environments with extreme temperatures, chemical exposure, and moisture, which means the markers must resist wear and tear.

Customization options allow for tailored solutions that fit an industry’s specific needs. For instance, customized pipe markers with precise measurements, colors, and materials can be crafted using Laser Engraving Services Canada. Laser engraving provides long-lasting, high-quality markers that remain legible even in challenging environments. This method ensures your facility adheres to safety regulations and operational efficiency requirements. Investing in durable and customized markers ensures compliance is maintained without frequent replacements.

Enhancing Compliance with the Right Tools

As regulatory demands evolve, so must the tools used to ensure compliance. Organizations can stay ahead of regulatory requirements by partnering with a trusted vendor and protecting their employees, facilities, and reputation. Looking ahead, trends in regulatory compliance may increasingly favor innovative materials and advanced customization techniques, ensuring safety standards continue to evolve alongside industrial advancements.