Tungsten Inert Gas (TIG) and Metal Inert Gas (MIG) welding became a ground-breaking solution in the 1940s when conventional welding techniques could not fuse aluminum and magnesium alloys. The success of these welding processes led to their widespread adoption across various industries. MIG and TIG welding utilizes an electric arc and a shielding gas to fuse metals. Despite their apparent similarities, each possesses unique characteristics of its own. Let’s examine more closely how the two most popular welding techniques differ.

The welding process.

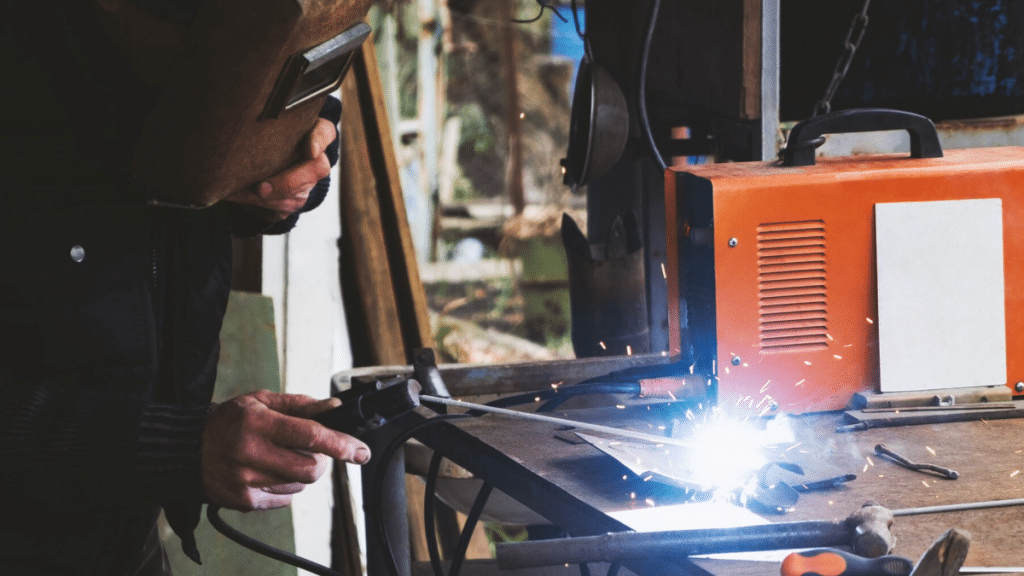

MIG welding combines two pieces of metal using a consumable electrode. TIG welding is an electric technique that joins workpieces using a non-consumable electrode. In both cases, the weld region is heated with an electrical current until a molten metal joint occurs.

Applications

The high precision TIG welding is typically the method of choice for complex welding tasks, mainly when working with thin materials like aluminum, stainless steel, and non-ferrous metals. Typical applications include the aerospace and electronics sectors, where precision, visual appeal, and high-quality welds are essential.

MIG Welding, on the other hand, is suitable for thicker materials. It welds them more quickly and effectively, increasing its popularity in the manufacturing, construction, and automotive industries.

Shielding gas

To prevent contamination, TIG welding utilizes pure argon or a combination with another non-reactive shielding gas, like helium or nitrogen. On the other hand, MIG welders frequently utilize argon and carbon dioxide blends because they allow for more penetration and work better with thicker materials.

The velocity at which the material is ejected on the torch is another crucial distinction between MIG and TIG welding. A TIG welding gun needs a gas flow of 15-25 cubic feet per hour, but a MIG welder normally operates its gas at 35-50 cubic feet per hour.

Equipment and setup

TIG welding requires more sophisticated equipment, such as a gas supply, filler material, tungsten electrode, and power supply. This may result in a longer setup time and a less portable procedure. On the contrary, MIG Welding has a more straightforward setup consisting of a gas supply, wire feeder, welding gun, and power source. This increases its convenience for quick and on-site welding jobs.

Weld quality

TIG Welding provides greater control of the welding process, which lowers the possibility of a poor weld by producing a cleaner, more accurate weld with less distortion and spatter. According to Micro Weld, Inc welding experts, TIG welding technology is suitable for crucial applications where weld precision is vital, such as the aviation industry.

MIG Welding: This method produces decent weld quality at a reasonable speed, allowing the business to produce more in a given period. However, because of the higher deposition rates, the welds could not be as exact as those made with TIG welding; consequently, the welds might not be suitable for use in specific applications, especially those that require high precision.

Final thoughts

The welding circumstances dictate when to apply MIG and TIG procedures. Identifying the materials involved in your project is critical to determining which welding technique is ideal for you.