PVC flooring sheet is a new, versatile, and lightweight decoration material worldwide. Despite being light in weight, the strength of the PVC flooring sheet is admirable. Considering the strength and lightweight of PVC flooring material, the applications of these sheets have been found at different places such as factories, schools, buildings of offices, businesses, and supermarkets.

On the other hand, polypropylene, also referred to as PP, has a wide range of industries in its applications, including the thermal underwear industry, packaging industry, automotive components, and laboratory equipment. Nevertheless, the significant application of polypropylene is found in the manufacturing of PP flooring, which is mainly used in floors due to its load rating, durability properties, and chemical resistance.

Differences between the PVC Flooring Sheet and PP Floor

Here we will draw a comparison between PP floors and PVC flooring sheets, which have a popular usage nowadays, based on their features, components, physical appearance, applications, and processing steps. Along these lines, the following are the main differences between these two materials:

1. Materials

PVC flooring sheets include raw materials of polyvinyl chloride powder and calcium carbonate with a proportion of 1 and 3, respectively. Apart from that, PVC flooring sheets add components such as fillers and colorants to form a durable and customized PVC flooring sheet. Usually, by changing the composition of PVC plasticizers that include PVC formulation, the properties of the sheets can be altered according to the requirements.

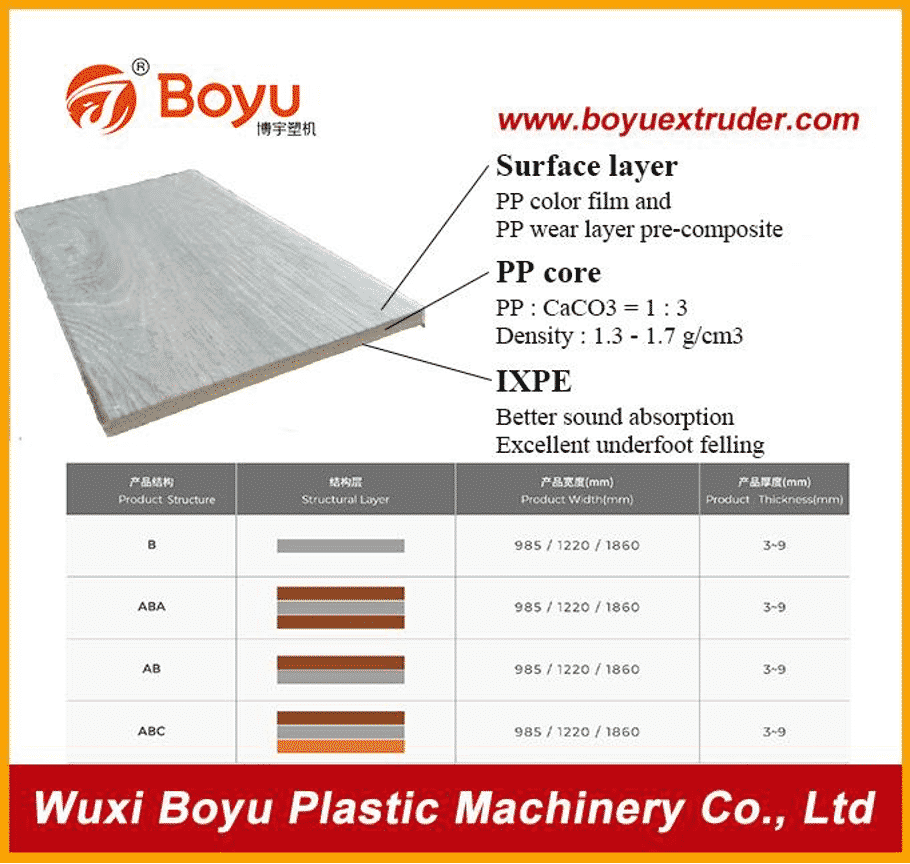

Meanwhile, the PP flooring comprises polypropylene (plastic material) and is well-known for its remarkable qualities. The components PP floor includes polypropylene modified material and calcium carbonate as raw materials, along with the addition of stabilizers, plasticizers, lubricants, and other additives like resins to add to the strength and durability of the material.

2. Appearance

The PVC flooring sheets usually come in the form of large, continuous, and durable sheets that offer extensive resistance against fatigue and the impact of water. In the interim, the appearance of the PVC flooring sheet is derived from the selected texture chosen and the wear layer.

PP sheets require a higher number of additives like plasticizers to reach higher softening material because their melting point is higher. Although the number of additives in PP sheets is more than the PVC flooring sheets, it still exhibits semi-rigidity. The physical appearance of the sheet is the same as the chosen texture and depends on the wear layer as well as the color film spread over it.

3. Applications

PVC as a material has a massive list of applications that belongs to diverse industries. However, the PVC flooring sheet is an application used at numerous places like hospitals, offices, airports, bedrooms, shopping malls, and flooring of the house.

When it comes to the PP flooring, they are mainly used as floor tiles in the home, as they offer excellent resistance against chemicals and bring more capacity to the flooring of fire resistance. Other than that, these sheets are also useable for commercial purposes.

4. Features

When it comes to the PVC flooring sheet, it possesses the following features:

- Compared to most plastics, PVC offers the highest density.

- PVC is readily available and usually costs less than PP.

- These floorings provide excellent hardness and durability.

- It presents superior tensile strength.

- The sheet width and thickness can be 1220-1830mm and 1-8mm, respectively.

Similarly, the PP flooring has some differentiating features such as:

- These sheets have better toughness, sound absorption, lower density, and lighter weight.

- These flooring sheets have reasonable integral hinge property.

- It presents stable performance and a reduced failure rate.

- Polypropylene material is recyclable and degradable.

- PP floor is chemical resistant, fire-resistant, halogen-free, and smoke-free.

- The sheet width and thickness can be 985-1860mm and 3-9mm, respectively.

5. Processing Steps

The manufacturing of the PVC flooring sheet starts with the quality virgin material. The additives and resins are readily added with the primary material to achieve the specific properties, and PVC powder is heated and flat-rolled during the process. In the end, wear layer, textured film, and PVC sheets are stacked together to turn it into a luxury PVC flooring sheet. The same is the case with PP flooring sheets; the difference occurs in the additives.

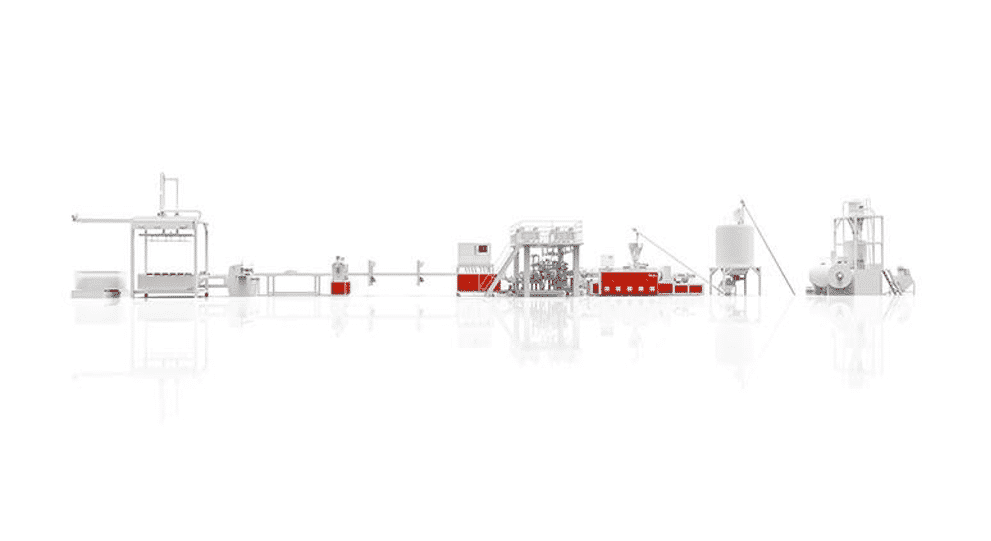

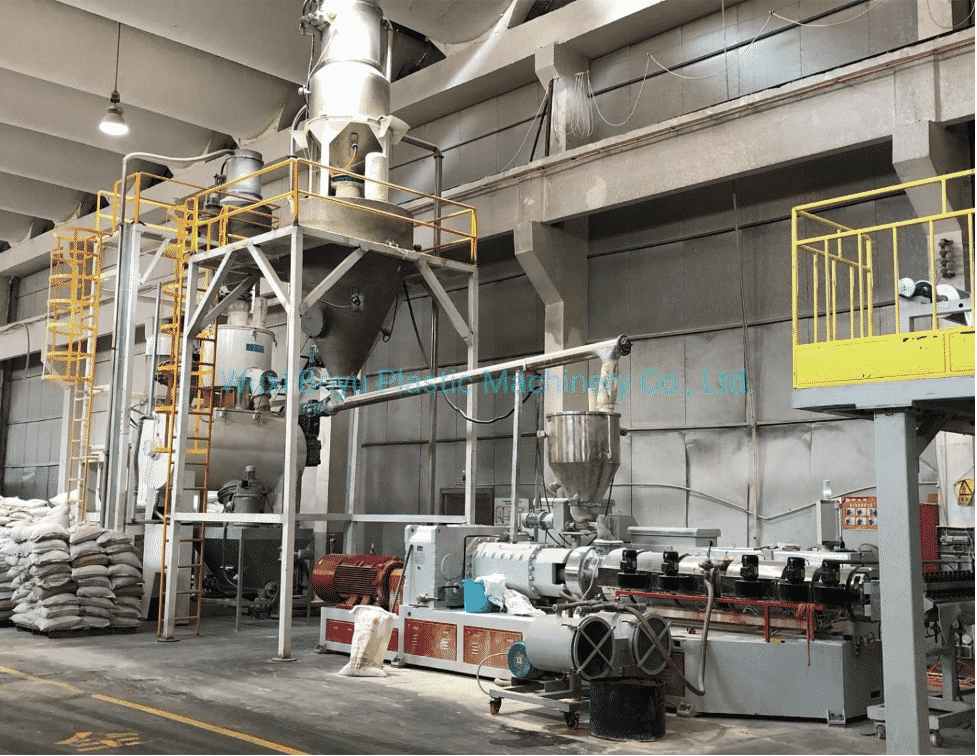

After knowing the components, appearances, applications, features, and processing steps of PVC flooring sheets and PP floors, can we recommend a platform that best meets your requirements? So, here comes the name of Boyu, which always ensures standardized production, advanced equipment, and a high degree of automation for the PP and PVC flooring production line. Boyu is constantly committed to providing you with the best products with professional services. Not only that, but the product from Boyu also guarantees your output products with fire-resistant. They are pleasant to be your priority choice. Both PP and PVC flooring production lines own the following merits:

- Power-saving

- High-productivity

- Intelligent electronic control system

- Stable performance and low failure rate

As the scope, features, and application of PP and PVC flooring sheets are extended and purely beneficial, the business in these products has lucrative chances for investors to grow. Then, suppose you are looking to cash this opportunity. In that case, you might take the help of innovative PP and PVC flooring extrusion production lines streamlined by Boyu integrating reliable design, production, and sales/after-sales services. Contact us now for more details.