Workplace and home-related accidents are an unfortunate reality in today’s modern world. With so many appliances, devices, and electrical-powered accessories in our lives, we need added protection against unwanted errors.

This is where a properly installed thermal protector switch can help increase the safety and security of our homes, offices, job sites, businesses, and more. A resettable thermal cutoff switch works by breaking an electrical circuit whenever it reaches a pre-designated temperature. It helps to protect the rest of the circuit from potential damage and allows the system to cool before being used again.

A quality thermal protector switch is designed with precise specifications that determine the highest safe operating temperature of the various components and then cut off power when the lowest of these temperatures are reached.

1. Where Can The Thermal Protector Switch Be Applied?

The very name “thermal protector switch” implies a use case related to temperature. That is why you will find these valuable devices like thermostats and overheating protection in a wide variety of heating and cooling equipment like refrigerators, washers, dryers, microwaves, space heaters, and more.

The idea is to protect any device that may overheat from stopping the flow of electricity or detecting a change in the environment. It opens the possible application of these motor overheat protection switches in items like power supplies, fans, motors, transformers, battery packs, pumps, and anything else that may need heat-restricted safety measures like coffeemakers and even hairdryers.

2. What Is A Thermal Protector Switch Made From?

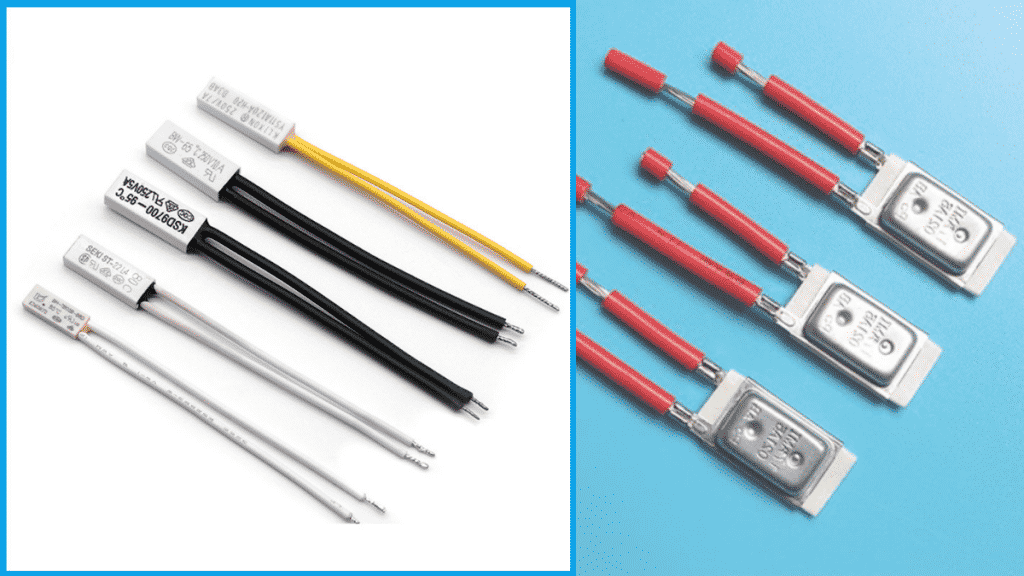

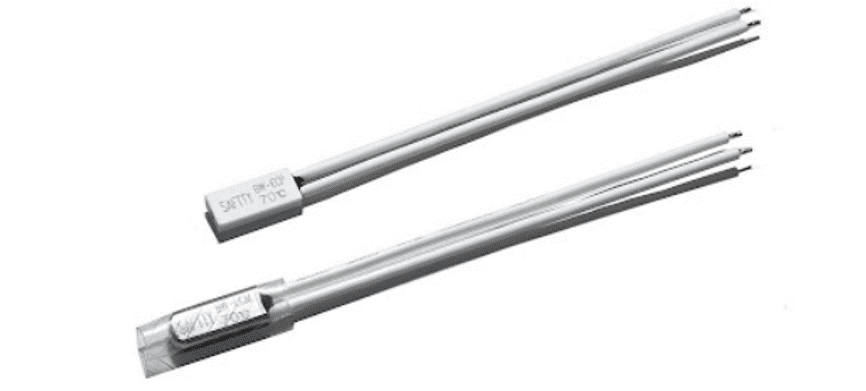

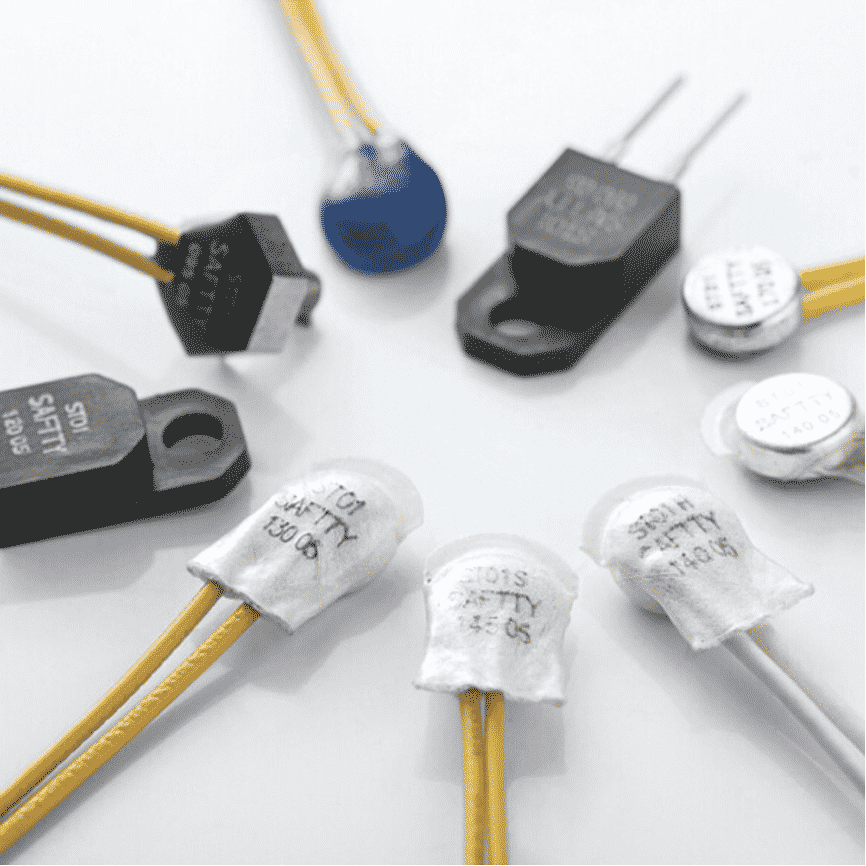

Several different makes and sizes of thermal protector switches are used depending on the required industry and product. For example, it can include bimetallic discs, mercury switches, rod and tube, and gas-actuated.

The most common thermal protector switch found in electronics is a thermal reed switch. This consists of a pair of contacts on hermetically sealed ferrous metal reeds actuated by a magnetic field. They can be made incredibly small and lightweight with enough durability to ensure a quality-made product around motors and circuitry.

3. Why Are Thermal Protector Switches Installed?

Many regulatory boards required the clean and safe installation of thermal protector switches to protect consumers from manufacturing, use, or environmental errors. For example, many boilers and heating systems in colder climates require a thermal protector switch as part of their regular operation. As a result, the boiler stops producing heat when the switch detects the preset temperature has been reached.

As for safety, consider the ordinary clothes dryer sitting in homes across the world. Without a way to cut off power in the event of overheating, the appliance could cause extreme potential damage by melting components, sparking a fire, or harming the user.

4. How Has The Thermal Protector Switch Developed?

Protecting human beings wasn’t the only reason for creating a thermal protector switch. There are many hard-to-make and difficult-to-install components in modern appliances, motor-driven systems, and advanced circuitry technologies that are cost-prohibitive to replace.

Ensuring the user is safe while making sure separate components operate at their best efficiency has caused the thermal cutoff to be developed into smaller and more specific form factors. This, coupled with the ability to reset some switches manually, has led to many industries adopting the switch as a standard feature.

5. Where To Find Quality-Made Thermal Protector Switches?

There are many international suppliers and manufacturers of thermal protector switches. However, finding the right one can pose a difficult challenge. That is why working with an experienced company like Saftty is so beneficial.

1. Industry Experience

Saftty has more than 13 years of experience with a strong history of emphasizing research and development for new products. With these years’ development, Saftty has enlarged the company size to more than three thousand square meters. As a member of the National Technical Standards Committee, Saftty commits to the innovation of the thermal protector industry.

2. Strict Quality Control

When you contact Saftty to help build and create customized solutions, you don’t have to worry about quality. They have no less than six separate systems to ensure proper quality control of every product they design, manufacture and develop. What’s more, they have imported SVM image measuring machines to observe the structural and surface characteristics of the products. High and low-temperature testing, X-ray testing, voltage-endurance testing, all these testing are required to ensure the product quality.

3. Strong R&D Ability

Saftty R&D team has experienced experts. Within five years of company establishment, the R&D team has developed more than ten new thermal protectors models and patented seven national inventions. It is worth mentioning that the ST01 series is the first China-made round shape thermal protector that got the UL and TUV certified and broke 30 years’ monopolization of Germany.

4. Customized Serves

One of the bright spots of Saftty is customized serves. Saftty commits to solving product problems by designing and producing the specified products depending on customers’ needs. Their industry-leading capability of providing customized solutions makes them continuously at the forefront of future developments and solidifies their reputation of delivering excellent results.

Start Your Order Today

If you would like to learn more about the qualifications and abilities of the expert team at Saftty, reach out to their support staff today. You can call them directly, email, Skype, or submit a form on their website. They will respond quickly and consult you on the best solution for your thermal protector switch needs.