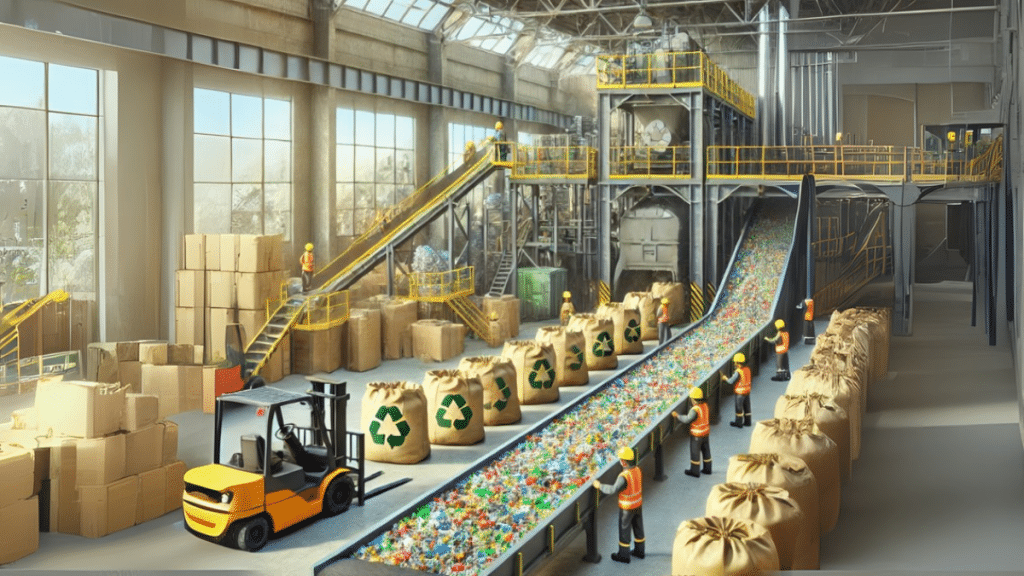

Environmental discussions today at the global scale bring to light plastic waste. From being an initiative in controlling pollution, it is an urgent step towards the fight against climate change as emissions are happening at all steps, from manufacturing to waste disposal. This blog looks at new ways in which this may change how we treat plastic waste. We will talk about cutting virgin plastic production, upgrading the recycling infrastructure, plastic waste management, and decarbonising the plastics industry. There is also an element of the Banyan Nation as an Indian leader in sustainable solutions for the circular economy.

The Role of Plastic Waste Management in Climate Action

Plastic waste managementis critical when handling issues related to climate change. Plastics, especially virgin plastics, require a lot of energy for manufacture and disposal, most of which comes from fossil fuels. This produces a lot of carbon, which causes rapid global warming.

Therefore, the result means that the global plastic industry would be the largest polluter of greenhouse gases. In the fight against it, governments and enterprises have to opt for sustainable ways of reducing the waste of plastics.

A beacon of hope in that direction is the Global Plastics Treaty, which seeks to bring plasticpollution into climate action. It aims to help industries build a better future by adopting responsible sourcing and steady incorporation of recycled materials within supply chains.

The 40×40 Target: A Bold Goal for Plastic Waste Management

The most ambitious target for the plastic waste management space is “40×40.” This means reducing virgin plastic production by 40 per cent by 2040, whereas 2025 will remain the baseline. If achieved, this would change the course of the plastics industry and greatly reduce its climatic footprint.

Why the 40×40 Target Matters?

- Severe Cut-Back on Virgin Plastic: For every tonne of virgin plastic produced, 40% less, which would end 371 million tonnes of primary plastic yearly from hitting the market. This would amount to an aggregate of 2.7 billion tonnes in the next 25 years.

- Climate Change: Under the umbrella of the global climate goal through Paris, bring an essential unity to the plastics industry about an issue that it cannot have without climate-related problems: plastic pollution.

Another important aspect of this target is the huge push for industries to make changes rather than “business as usual ” and for innovations beyond their imagination in managing plastic waste.

Paths toward Achieving the 40×40 Goal

The 40×40 goal is a challenging feat but rather requires a collective global effort. There are two distinct paths toward this possibility:

1. Business-As-Usual Demand Scenario

This would mean the industry continues to grow on its current trajectory of plastic demand. However, if this were to be the way the 40×40 target was achieved, then the world’s recycling rate would have to balloon to 63% from its current 10%.

Challenges: A tenfold increase in recycling capacity would require unprecedented investment in recycling infrastructure, innovation, and policy support.

Opportunities: This route focuses on improving high-end recycling technologies and provides a sound foundation for the international recycling infrastructure.

2. Reduced Demand Scenario

This route targets reducing the total demand for plastic by 35%, which would also lower the recycling rate, which now has to be just 43%.

Strategies: This can be achieved through policies that promote product reuse, redesign of packaging systems, and incentives to recycle content.

Impact: Reduction will help create a much more sustainable plastics waste management regime, which will relieve some pressure on recycling.

The two routes make it clear that recycling will have a basic role to play in reaching the 40×40 target but cannot be recycled. Equally, the reduction of demand for virgin material and changing production systems must be crucial.

Decarbonizing Plastics: Beyond Traditional Recycling

As for plastics management, it shall rest heavily on recycling. It still requires efforts that can assist with the decarbonization of the plastics industry. A few strategies toward this transition are:

Electrify Production

Plastic manufacture is highly dependent on fossil fuels and energy sources for processing. Transitioning from fossil fuel-based steam crackers to renewable energy would enable a 30% drop in the production of common plastics like polyethene and polypropylene.

Chemical Recycling and Bio-Based Plastics

- Chemical Recycling: Chemical recycling can be used to recycle plastics that are not recyclable through mechanical recycling. Thus, it is an important part of managing difficult-to-recycle materials.

- Bio-Based Plastics: Bio-based plastics derived from renewable feedstocks, such as bio-ethylene, can replace fossil fuel-based plastics.

Renewable Energy Adoption

If renewable energy sources, such as green hydrogen, are used for heating and electricity, plastic production can significantly reduce the industry’s carbon footprint.

Policy-Driven Demand Reduction

Governments play a crucial role in shaping consumer and industry behaviour. Policies that promote the use of recycled content, restrict single-use plastics, and encourage the development of reusable products can drive significant demand reduction.

The Urgency of Plastic Waste Management

Time is of the essence. Reports say plastics may take half of the world’s carbon budget in 2050 if action is not taken immediately. This alarming statistic calls for immediate adaptation to sustainable plastic waste management practices.

The next five years are crucial. The Global Plastics Treaty is considered a once-in-a-lifetime opportunity to set definitive targets for reductions and help technologies in advanced recycling. Of course, for that to happen, everybody needs to work in coordination—businesses, governments, consumers, etc.

Banyan Nation – Leading the Plastic Waste Management

Banyan Nation leads the new wave of innovation in plastic waste management across the organisation, both within and outside its country. As one of the earliest movers of plastic circularity, Banyan Nation works to develop human-contact-safe traceable recycled plastics branded with rPE and rPP resins. This has allowed them to stay abreast of such high standards and continually meet excellent technical, colour, and odour standards.

Banyan Nation has been helping companies meet their global sustainability commitments by supporting dozens of leading brands in switching from virgin plastics to circular recycled plastics and ensuring they meet their Extended Producer Responsibility (EPR) obligations.

Other than recycling, Banyan Nation’s work promotes a more comprehensive approach to sustainability. This organisation is changing how the plastics industry is constructed. Promoting the use of recycled materials, reducing the consumption of virgin plastics, and encouraging these factors shows that a clean and greener future in sustainable plastic waste management is both possible and needed.