Stone plastic composite flooring, or SPC, has rapidly gained popularity as a resilient and aesthetically pleasing flooring option. Its unique combination of natural stone and plastic components offers durability, water resistance, and an array of designs. However, like any manufacturing process, stone plastic composite flooring production can encounter challenges that affect product quality. This article will explore common issues faced during SPC flooring production and discuss potential troubleshooting techniques to overcome them.

Introduction to SPC Flooring and Production Challenges

Stone plastic composite flooring has overtaken the market due to its exceptional qualities. It boasts the elegant appearance of natural stone while being maintained more affordable and easier. However, the intricate production process of SPC flooring involves several stages, which work together to contribute to the final product’s characteristics. It’s at these stages that production challenges can arise, impacting the overall quality of the flooring.

Production Process and Common Problems

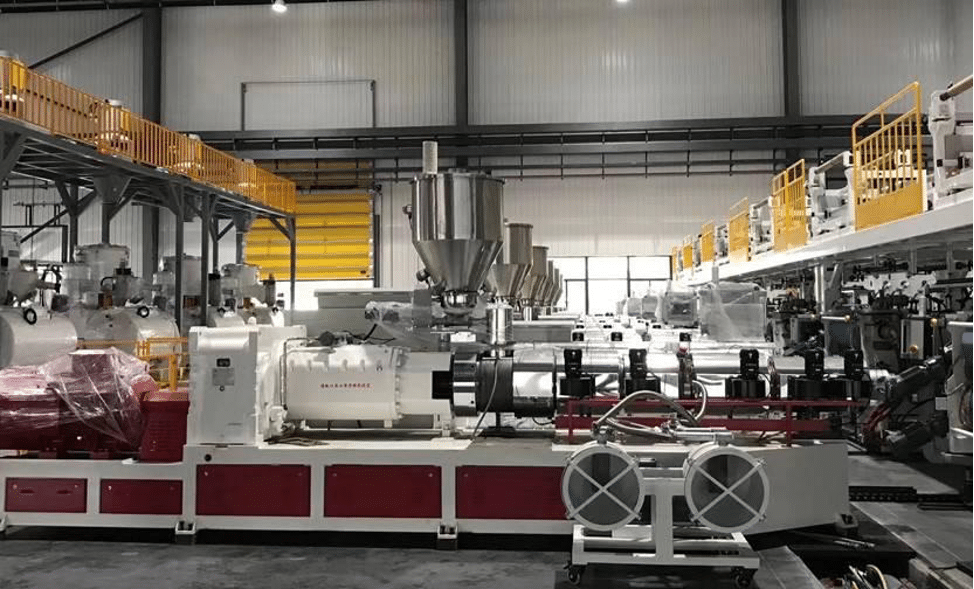

The production of SPC flooring involves a multi-step process, including crushing and milling of raw materials, mixing, extrusion, UV coating, slotting, V-groove painting, IXPE/EVA underlay laminating, and packaging. While this process leads to high-quality flooring, several problems may occur, posing hurdles for manufacturers. It could even mean the difference between using a twin screw extruder or a conical twin screw extruder to complete the job.

Unstable Size and Thickness:

Inconsistent sizing and thickness across SPC planks can result from improper mixing of raw materials or irregularities in the extrusion process. This issue leads to difficulties in installation and an uneven flooring appearance.

Shoddy Quality:

Low resistance and impact resistance are indicators of poor-quality SPC flooring. These problems can stem from improper material ratios during mixing or inadequate temperature control during extrusion, resulting in compromised structural integrity.

Bending and Deformation:

Bending or deformation of SPC planks might occur due to issues during the cooling and curing process. Insufficient cooling time or uneven temperature distribution can lead to warped flooring that is challenging to install and unattractive in appearance.

Recommending the SPC Flooring Extrusion Line

Investing in a reliable and advanced SPC flooring extrusion line is crucial to address these challenges and ensure consistent, high-quality stone plastic composite flooring. These specialized production lines integrate cutting-edge technology and process control mechanisms to optimize every stage of production. A well-designed extrusion line can effectively address issues related to mixing, extrusion, cooling, and curing, resulting in flooring products that meet the highest quality and durability standards.

Embracing Solutions and Recommending Boyu

In summary, while stone plastic composite flooring offers remarkable benefits, its production process demands meticulous attention to detail to overcome potential challenges. A manufacturer’s choice of production equipment plays a pivotal role in ensuring a streamlined and effective production process. Boyu stands out as a reliable partner when seeking solutions for SPC flooring production.

Boyu offers state-of-the-art stone plastic composite flooring production lines equipped with innovative features to address the challenges mentioned earlier. With a commitment to excellence, Boyu’s flooring production lines provide precise material mixing, consistent extrusion, controlled cooling, and other critical processes that result in flawless SPC flooring products.

Elevating Stone Plastic Composite Flooring Production

In the competitive world of flooring manufacturing, understanding and overcoming production challenges is essential to delivering top-tier products. Stone plastic composite flooring’s popularity stems from its impressive qualities, but these qualities can only be realized through a production process that ensures consistency, durability, and visual appeal.

Boyu’s commitment to excellence and cutting-edge flooring production lines make it a standout choice for manufacturers seeking to elevate their SPC flooring production. The intricate interplay of technology and expertise sets Boyu apart, ensuring that the SPC flooring produced not only meets but exceeds industry expectations. Manufacturers can unlock a world of possibilities by choosing Boyu, producing SPC flooring that embodies quality, resilience, and aesthetic appeal.

As the demand for high-quality SPC flooring continues to rise, partnering with a company like Boyu positions manufacturers at the forefront of innovation and success. With their distinctive selling points and proven track record, Boyu’s flooring production lines pave the way for manufacturers to create exceptional SPC flooring that not only meets market demands but also sets new standards in the industry. Embrace the potential of advanced technology and reliable expertise with Boyu, and witness your SPC flooring production reach new heights of excellence.