In the world of lasers and precision optics, every photon matters. Whether it’s cutting-edge research, medical procedures, or industrial applications, the efficiency and precision of laser systems depend on the quality of their components. Among these, plano-convex lenses with high-performance ion-beam-sputtered anti-reflection (IBS AR) coatings stand out as essential elements for achieving optimal performance.

Understanding Plano-Convex Lenses

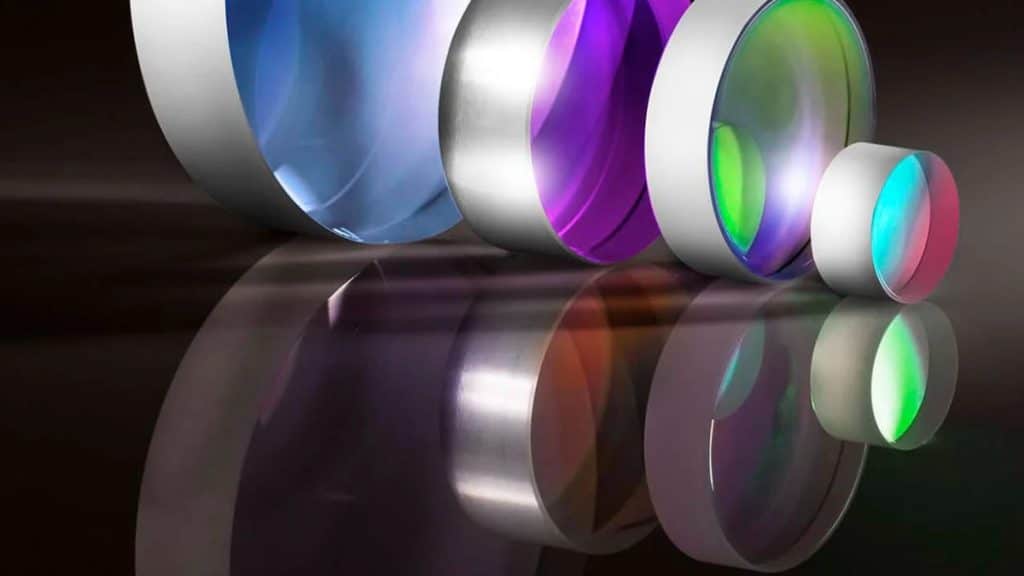

Plano-convex lenses are a fundamental optical element with a single convex surface and a flat (plano) surface. This simple yet versatile design finds extensive use in laser systems due to its ability to focus or collimate light effectively. The convex surface of the lens converges incoming light rays to a focal point, making it invaluable for applications such as beam shaping, focusing, and expanding laser beams.

Enhanced Focusing Capabilities:

One of the primary functions of plano-convex lenses in laser applications is to focus light into a precise point or line. By exploiting the convex curvature, these lenses can converge parallel incoming light rays to a focal point, allowing for highly concentrated energy deposition. This ability is indispensable in laser cutting, welding, and drilling processes, where achieving pinpoint accuracy is essential for intricate workpieces and minimal material waste.

The Importance of Anti-Reflection Coatings

In laser systems, minimizing light loss due to reflections is paramount. Uncoated optical surfaces can reflect a significant portion of incident light, leading to reduced efficiency and potential damage to sensitive components. This is where anti-reflection coatings come into play. By applying a thin, specialized coating to the lens surface, unwanted reflections can be greatly reduced, allowing more light to pass through the lens and improving overall system performance.

High-Performance Ion-Beam-Sputtered Coatings

Among various coating techniques, Ion-Beam-Sputtering (IBS) has emerged as a leading method for producing high-performance anti-reflection coatings. IBS involves bombarding target materials with energetic ions in a vacuum chamber, causing atoms to be ejected and deposited onto the lens surface. This precise deposition process results in coatings with exceptional uniformity, durability, and optical performance.

Advantages of IBS AR Coatings on Plano-Convex Lenses:

- High Transmission: IBS coatings can achieve transmission rates exceeding 99%, minimizing light loss and maximizing system efficiency.

- Broadband Performance: IBS AR coatings offer excellent performance across a wide range of wavelengths, making them suitable for diverse laser applications.

- Customizability: IBS technology allows for precise control over coating parameters, enabling the customization of plano-convex lenses to meet specific performance requirements, whether it’s for ultrafast lasers, high-power systems, or other specialized applications.

Applications in Laser Systems

Plano-convex lenses with high-performance IBS AR coatings find applications across various laser systems, including:

- Medical Lasers: From surgical procedures to diagnostic imaging, precision lenses with anti-reflection coatings are essential for delivering controlled and accurate laser energy while minimizing tissue damage.

- Industrial Lasers: Laser cutting, welding, and marking rely on efficient beam delivery and manipulation, where anti-reflection coated lenses ensure maximum throughput and reliability.

- Research and Development: In scientific research and experimental setups, where the performance and reliability of optical components are critical, IBS AR coated lenses play a vital role in achieving precise results.

In the realm of laser technology, the quest for precision and efficiency never ceases. Plano-convex lenses with high-performance ion-beam-sputtered anti-reflection coatings represent a pinnacle of optical engineering, enabling laser systems to unleash their full potential. With exceptional transmission, durability, and customizability, these lenses are indispensable for applications where every photon counts, driving innovation across industries and pushing the boundaries of what laser technology can achieve.