Storage tanks are critical components in various industries, including petrochemicals, agriculture, food and beverage, and water treatment. Over time, these tanks accumulate sediment, sludge, and other contaminants, necessitating periodic cleaning to maintain operational efficiency and safety. However, if not conducted properly, tank cleaning can pose significant hazards to workers, water tank inspection services professionals, and the environment.

In this blog, we will explore the hazards associated with storage tank cleaning and provide essential safety tips to protect both the tanks and the personnel involved in the cleaning process.

Understanding the Hazards:

Storage tank cleaning involves handling hazardous materials, confined spaces, and the risk of exposure to toxic gases and flammable substances. The presence of corrosive residues, volatile chemicals, and biological contaminants further complicates the cleaning process. Identifying and understanding these hazards is crucialIt’s before initiating any cleaning activities.

Risk Assessment:

Before embarking on tank cleaning, facility owners conduct a thorough risk assessment to identify potential hazards and develop appropriate control measures. They assess factors such as the type of stored material, tank size and design, ventilation systems, and emergency response procedures. To avoid any risk of contamination, it’s essential to engage with qualified personnel who have experience in risk assessment to ensure comprehensive hazard identification and mitigation.

Personal Protective Equipment (PPE):

Proper PPE is essential for workers engaged in storage tank cleaning to protect against chemical exposure, physical injuries, and respiratory hazards. PPE may include chemical-resistant gloves, goggles, respirators, protective clothing, and fall protection gear, depending on the specific risks involved. Ensure that all personnel are adequately trained in using and maintaining PPE correctly.

Ventilation and Air Monitoring:

Effective ventilation is critical to maintaining a safe working environment during tank cleaning operations. Implement ventilation systems to remove hazardous vapors, gases, and airborne contaminants from the tank’s interior. Facility owners should conduct regular air monitoring to detect the presence of toxic gases such as hydrogen sulfide, methane, and ammonia. Installation of gas detection equipment and establishment of alarm systems are also some of the ways to avoid storage tank hazards.

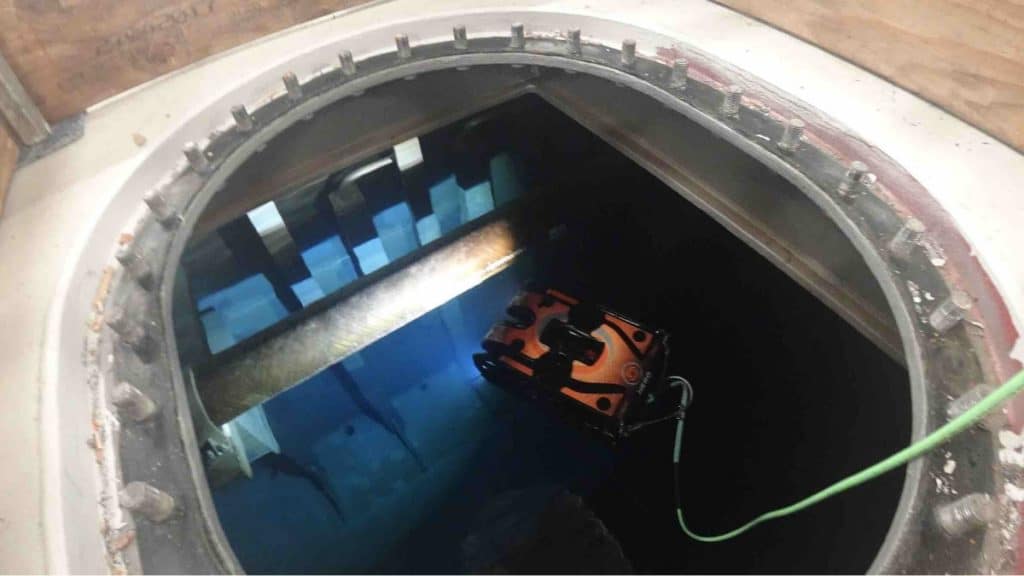

Confined Space Entry:

Many storage tanks are classified as confined spaces, posing additional risks to workers entering these environments. Before entering a confined space for cleaning purposes, one must follow established entry procedures, including atmospheric testing, permit issuance, and the presence of trained tank inspection services personnel as standby rescuers. Besides this, one must implement proper ventilation, lighting, and communication systems inside the confined space to ensure the safety of workers at all times.

Chemical Handling and Neutralization:

Storage tanks may contain residues of corrosive chemicals, hydrocarbons, or other hazardous substances that require careful handling during cleaning. Facility owners should use appropriate chemical neutralization agents to deactivate or neutralize reactive materials before initiating the cleaning process. Avoid mixing incompatible chemicals, as this can result in dangerous reactions and release of toxic gases.

Water Management and Waste Disposal:

Proper water management and waste disposal are essential considerations in storage tank cleaning operations. Minimize the use of water to reduce the volume of wastewater generated during cleaning. Implement containment measures such as berms, barriers, and absorbent materials to prevent spills and runoff into the environment. Dispose of wastewater and waste materials in accordance with local regulations and environmental guidelines.

Emergency Preparedness and Response:

Despite thorough planning and precautions, emergencies can still occur during storage tank cleaning operations. Facility owners should establish an emergency response plan that outlines procedures for dealing with spills, leaks, fires, and injuries. Furthermore, they should provide comprehensive training to all personnel on emergency protocols, evacuation routes, and first aid procedures. Maintaining adequate firefighting equipment, spill containment materials, and emergency communication systems onsite are some other ways to keep storage tank hazards at bay.

Regular Maintenance and Inspection:

Preventive maintenance and regular inspection of storage tanks are essential for identifying potential hazards and ensuring safe operation. Facility owners and operations are required to implement a scheduled maintenance program to inspect tank integrity, structural integrity, and corrosion resistance. This allows them to promptly address defects or deficiencies and prevent accidents and environmental contamination.

Conclusion:

Storage tank cleaning is a challenging task that requires careful planning, risk assessment, and implementation of appropriate safety measures. By understanding the hazards associated with tank cleaning, providing proper training and PPE to workers, implementing effective ventilation and air monitoring systems, following confined space entry procedures, handling chemicals safely, managing water and waste responsibly, preparing for emergencies, and conducting regular maintenance and inspection, we can protect both storage tanks and personnel from harm. Prioritize safety in storage tank cleaning operations to ensure a safe working environment and prevent accidents and environmental damage.