Have you ever faced the challenge of grinding down tough materials like concrete or granite and wondered what tool can handle the job? The answer is in the efficiency of cup wheels. These powerful tools are designed to make difficult tasks easier, saving time and effort. Whether you’re new to this tool or looking to refine your understanding, this guide will walk you through what cup wheels are, how they work, and which types are best suited for your projects.

What Are Cup Wheels?

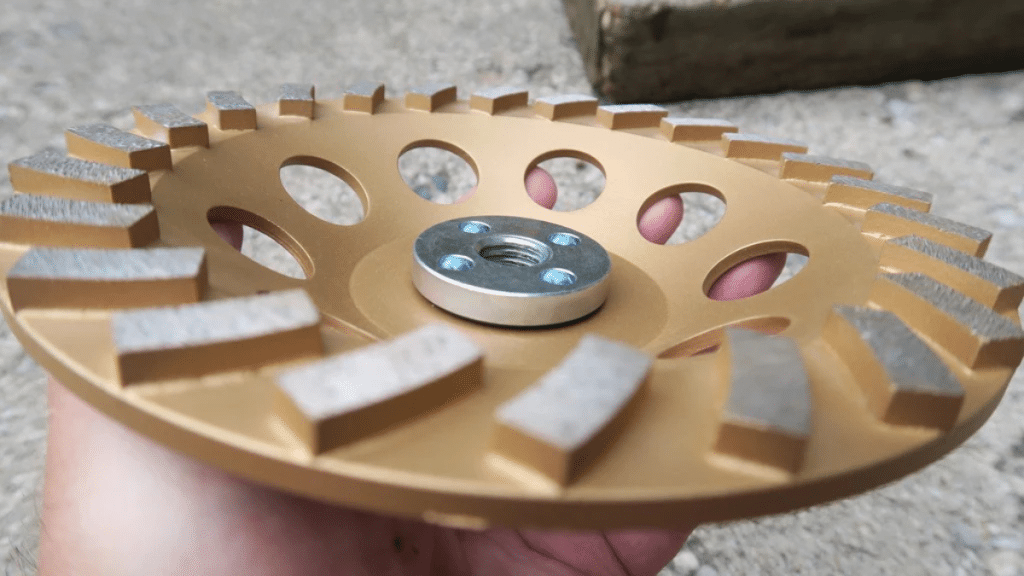

Cup wheels are diamond tools with a unique design. They get their name from their shape, which looks like an upside-down cup. Along the outer edge of this cup, you’ll find diamond segments bonded with metal. These diamond segments are the key part of the tool. As the grinder spins, the diamond segments grind away at the material you’re working on.

The use of diamonds in these tools isn’t just for show. Diamonds are one of the hardest materials known, and that’s why they’re used in cup wheels for cutting and grinding hard surfaces. Whether you’re working with concrete, granite, marble, or even asphalt, cup wheels will help you break down the material smoothly.

What Are Cup Wheels Used For?

The primary purpose of a cup wheel is to grind hard surfaces, such as concrete and stone. If you’ve ever worked on a project that involves cutting or grinding concrete, you know how tough that material can be. These tools are designed to handle the job by breaking down the surface layer by layer.

Here are some common uses for cup wheels:

- Concrete grinding: One of the most common uses for cup wheels is grinding down concrete surfaces. Whether it’s to smooth out rough patches or remove old coatings, these tools make the job easier.

- Granite and marble polishing: Cup wheels are also used for shaping and polishing hard stones like granite and marble. With the right technique, you can create a smooth, polished finish on even the hardest materials.

- Surface preparation: If you’re working on a construction project, you’ll often need to prepare a surface before applying a new coating or sealant. Cup wheels help remove old material coatings, adhesives, or imperfections.

- Asphalt work: Some specialized cup wheels can even be used for grinding and shaping marble, making them versatile tools for various surfaces.

Types of Cup Wheels

Not all cup wheels are the same. There are different types designed for specific tasks. If you’re working on a big project, choosing the right cup wheel will make a huge difference in time and efficiency. Let’s look at some common types of cup wheels:

1. Single Row Cup Wheel

A single rowcup wheel is designed with one row of diamond segments around the edge. This is a general-purpose tool that’s great for concrete grinding. It’s often used for light to medium grinding tasks, like removing thin coatings or surface-level imperfections.

2. Double Row Cup Wheel

The double row cup wheel is handy for tougher jobs. It has two rows of diamond segments, providing a smoother grind. If you’re working on thicker materials or need a more even finish, this wheel will do the job faster.

3. Turbo Cup Wheel

The turbo cup wheel is your best option if you need to grind tough materials like granite or marble. It’s designed for fast, aggressive grinding, and its unique design allows for more air to flow through, keeping the tool cooler while working.

4. PCD Cup Wheel

The PCD (Polycrystalline Diamond) cup wheel is perfect for removing thick coatings, paint, or glue from concrete. It’s a heavy-duty tool that can handle hard materials and coatings without wearing out quickly. This wheel type is often used for surface preparation, especially in construction projects.

5. Resin-Filled Cup Wheel

A resin-filled cup wheel polishes hard surfaces like marble and granite. The resin helps reduce vibration during grinding, giving you a smoother and more polished finish.

How to Choose the Right Cup Wheel

The choice of cup wheel depends on your project. Here’s what to consider when making your decision:

- Material Type: Different materials require different types of cup wheels. If you’re working on concrete, look for wheels labeled as concrete grinding wheels. For granite and marble, turbo or resin-filled cup wheels are better suited. Asphalt, on the other hand, may require a PCD cup wheel.

- Job Size: If you’re working on a smaller, lighter job, a single row cup wheel might be enough. For larger projects, consider a double row or turbo wheel to get the job done faster.

- Finish: For a smoother finish, go with a double row or resin-filled cup wheel. These provide better control and reduce the surface roughness.

- Tool Compatibility: Ensure that the cup wheel you choose fits your grinder. Cup wheels come in different sizes, and matching them with the correct tool is important to avoid any damage or safety issues.

Tips for Using Cup Wheels Safely

Safety is always important when using power tools. Cup wheels are no exception. Here are some tips to ensure safe and effective use:

- Wear Protective Gear: Wear safety goggles, gloves, and ear protection when grinding. Dust from concrete and stone can be harmful if inhaled, so a dust mask is also recommended.

- Use the Right Speed: Make sure your grinder is set to the correct speed for your cup wheel. Some materials, like concrete, require higher speeds, while others, like granite, may need slower speeds.

- Keep the Wheel Cool: Overheating can cause cup wheels to wear out faster. Take breaks during grinding to let the tool cool down, or choose a turbo cup wheel with better airflow.

- Secure the Material: Ensure the material you’re grinding is stable and secure. This will prevent it from moving during grinding and reduce the risk of accidents.

Conclusion

Are you equipped with the right cup wheel to handle your toughest tasks? Selecting the proper tool can significantly improve your results, whether you’re working with concrete, granite, or other hard surfaces. With the right cup wheel, your work becomes more efficient, and the finish is smoother. Tait Sales & Consulting offers a wide selection of high-quality cup wheels designed to meet the needs of seasoned professionals and those new to the industry.