The woven mesh conveyor belt is a true workhorse in the manufacturing sector, relentlessly and dependably transporting products from one location to another. However, its usefulness goes beyond just transportation; its versatility is applied in a variety of industries, revolutionising workflows and boosting output.

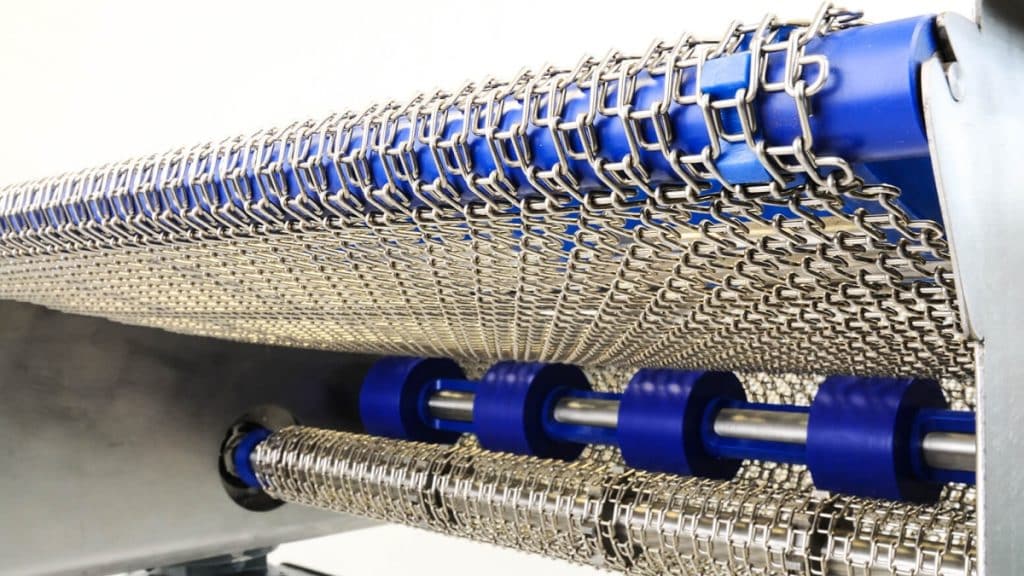

Conveyor belts with woven mesh are constructed from metal wires that are woven together to create a continuous mesh. These belts are frequently used in various industries, including electronics assembly, automotive manufacturing, and food processing.

Conveyor belts with woven mesh come in a range of configurations, which enable customisation according to particular application needs. These configurations include varied wire diameters, mesh sizes, and materials (such as stainless steel, carbon steel, or galvanised steel). They are used in many different manufacturing processes to transport a variety of goods, such as food products, parts, components, and materials.

Let’s examine the various uses of woven mesh conveyor belt as we delve into this complex industry.

1. Food Industry

Conveyor belts with woven mesh are essential in the food business, where safety and hygienic practices are of utmost importance. Strict food-grade criteria are met in the construction of these belts, guaranteeing regulatory compliance. Their open mesh design makes cleaning easier and keeps bacteria and debris from building up. Woven mesh conveyor belts offer a seamless solution for processing a variety of food products, including baked goods, fruits, vegetables, meats, and dairy, from baking to freezing, sorting to packaging.

2. Automotive Sector

Efficiency and precision are essential requirements for manufacturing operations in the automotive industry. Conveyor belts with woven mesh provide a way to move parts along the manufacturing line. These belts offer the sturdiness and dependability required for continuous workflow, whether they are being used for painting and finishing operations, moving materials through heat treatment procedures, or carrying parts for assembly. Their adaptable designs enable automated system integration, maximising manufacturing effectiveness and reducing downtime.

3. Recycling and Waste Management

Effective material handling is essential to waste management and recycling procedures. Conveyor belts with woven mesh are necessary for conveying, sorting, and separating recyclables like glass, paper, plastic, and metal. Their open mesh design facilitates efficient liquid drainage and sorting, and their sturdy structure endures the rigours of heavy-duty operation. These belts support environmental sustainability and resource-saving by making it easier for materials to travel through different processing phases.

4. Electronics and Semiconductor Manufacturing

Woven mesh conveyor belts are a perfect solution for handling sensitive components and substrates in the electronics and semiconductor production industries, where accuracy and contamination control are crucial. Sensitive electronic equipment is kept intact by its anti-static qualities, which reduce the possibility of electrostatic discharge. Their flawless surface finish also inhibits the formation of particles, lowering the likelihood of contamination in cleanroom settings. These conveyor belts assist in the sophisticated manufacturing processes that spur innovation, from wafer processing to PCB assembly.

5. Pharmaceutical and Chemical Industries

Conveyor belts with woven mesh are widely used in chemical and pharmaceutical sectors, where stringent adherence to quality and safety requirements is necessary. These belts are perfect for transporting dangerous chemicals or fragile pharmaceutical supplies since they are resistant to abrasion, corrosion, and chemical exposure. Their non-stick surface qualities make cleaning easier and guard against product contamination, guaranteeing adherence to strict industrial standards.

Conclusion

Conveyor belts with woven mesh have been shown to be handy and adaptable instruments in many different sectors. It still has a significant impact on improving productivity, safety, and efficiency in all industrial sectors. Despite the rapid advancements in technology and industry changes, the basic yet essential conveyor belt continues to be a timeless icon of material handling innovation. Conveyor belts with woven mesh construction from Wirebelt provide excellent drainage and ventilation, which makes them appropriate for uses where air or liquid must pass through the belt. They are renowned for their strength and resilience as well, which enable them to bear hot temperatures and handle big loads.