In today’s industrial and commercial landscapes, working at height is a routine part of many job roles, yet it remains one of the leading causes of workplace injuries. That’s why installing a fall protection system is more than a precaution; it’s a critical step in protecting both people and operations. Whether you’re designing a new facility or upgrading an existing one, knowing what to consider before installation can make the difference between a compliant setup and one that genuinely protects your team. With trusted experts like HySafe, businesses can navigate the process of system selection, design, training, and maintenance with confidence. The right fall protection system doesn’t just save lives, it supports long-term operational resilience.

Start with a Comprehensive Hazard Assessment

Before choosing any equipment, companies must evaluate where and how fall risks occur in their operations. Every facility is different: flat and sloped rooftops, mezzanines, skylights, loading docks, ladders, and maintenance areas all present unique hazards. A proper fall protection system must be tailored to each of these scenarios. This assessment forms the foundation for choosing the right combination of equipment and controls.

Understand the Types of Fall Protection

There are three primary approaches to fall protection: fall prevention, fall restraint, and fall arrest. Fall prevention methods, like guardrails and barriers, stop a fall before it starts. Fall restraint systems limit a worker’s range so they can’t reach the edge, and fall arrest systems stop a fall mid-air if one occurs. The best system often uses a mix of these strategies, based on the specific needs of the facility.

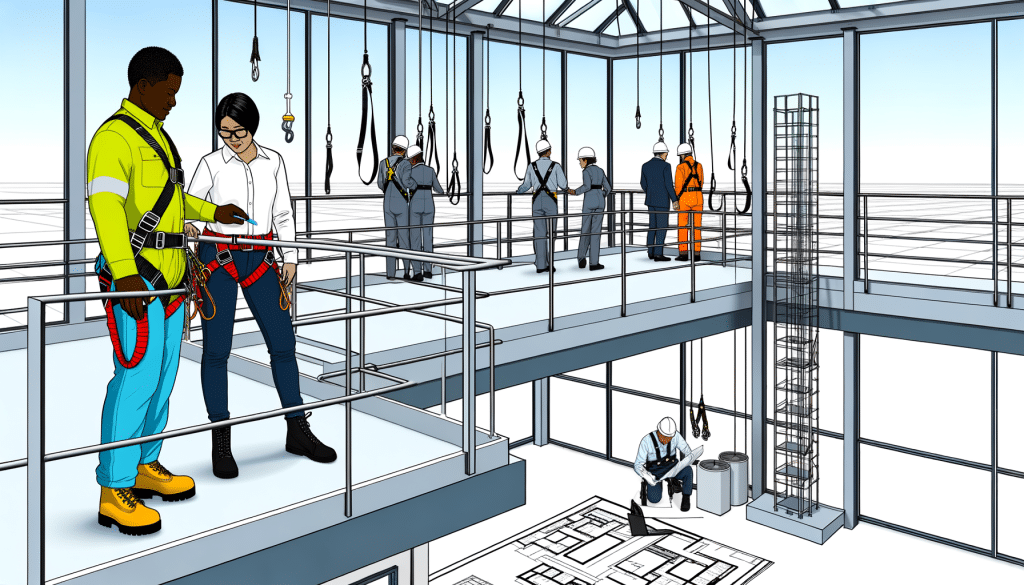

Consider System Design, Layout, and Usage

Installing fall protection isn’t just about buying gear, it’s about designing a system that integrates with your operations. For example, will workers need overhead anchor points for indoor maintenance, or rooftop tie-offs for outdoor work? Will mobile systems be needed for flexibility, or is a permanent guardrail more appropriate? HySafe works closely with clients to create solutions that account for workflow, equipment, structural constraints, and ongoing use.

Plan for Training, Maintenance, and Compliance

A fall protection system must be installed correctly, inspected regularly, and used properly to remain compliant and effective. That means planning for employee training, annual inspections, and documentation. OSHA and ANSI standards change, so it’s important to work with a provider that stays up to date and offers long-term support. Routine maintenance ensures that the system performs when it’s needed most, and helps avoid costly repairs or fines down the road.

Think Ahead with Scalable Solutions

As your business grows or shifts operations, your fall protection needs may change. That’s why scalable, modular systems are often the best investment. Whether you’re adding new equipment, expanding your facility, or updating workflows, a flexible system can adapt with you, without requiring a full overhaul.

FAQs: Installing a Fall Protection System

1. What’s the first step in installing a fall protection system?

Begin with a hazard assessment. Identify all locations where workers are exposed to fall risks and determine the best methods to control those risks.

2. What industries benefit most from fall protection systems?

Construction, warehousing, manufacturing, logistics, food processing, and utilities are among the most common, but any industry involving elevated work areas can benefit.

3. How long does installation typically take?

The timeline varies depending on the complexity and size of the system. Smaller installations may take a day or two, while large-scale solutions could take several weeks.

4. Do all fall protection systems need to be permanent?

No. Many systems are modular or mobile, especially for temporary work or job sites. However, permanent systems are often preferred for high-traffic or high-risk areas.

5. How often should systems be inspected?

At a minimum, systems should be inspected annually, with additional inspections after any major event or modification. OSHA requires regular checks and documentation.

Conclusion

Installing a fall protection system isn’t just about ticking off a safety requirement, it’s about future-proofing your workplace with systems that are reliable, scalable, and aligned with your unique operational demands. A well-planned approach, rooted in assessment, strategic design, and ongoing support, ensures that your investment provides long-term value. Companies that prioritize this kind of foresight don’t just reduce liability; they foster a workplace culture built on care, compliance, and performance. With comprehensive solutions from experienced partners like HySafe, businesses are better equipped to protect their most important asset, their people, while staying ahead in an increasingly safety-conscious world.