In today’s workplaces, keeping the space clean and safe is crucial. An extraction arm is a key tool that helps achieve this. This equipment is essential for removing particles, fumes, and dust from work areas. Knowing how it works and its advantages can guide businesses in making the right choices about acquiring this tool.

A standard extraction arm is a vital tool for maintaining clean and safe work environments. Designed to capture harmful contaminants like dust, fumes, and smoke directly at their source, it helps improve air quality, protect employee health, and meet safety standards in industrial, laboratory, and other professional settings.

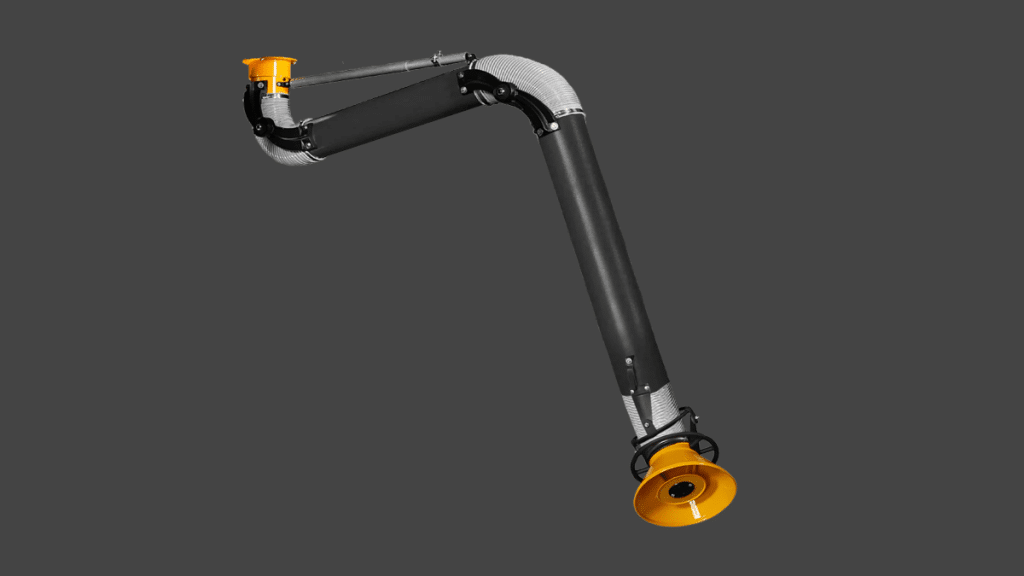

The Basics of a Standard Extraction Arm

In some work environments, one often comes across a type of versatile extraction arm that is meant to effectively capture airborne impurities at the source. This is done by adjusting itself freely in various positions through its segmented structure. These devices are crucial in sectors such as welding and pharmaceutical industries to maintain proper air quality and ensure worker safety and efficiency are not compromised. A standard extraction arm plays a role in eliminating substances to safeguard workers from respiratory ailments and other health risks.

Important Elements

Extraction arms commonly used are built to be sturdy for lasting durability and reliability purposes. Various parts like hoods and tubes collaborate to offer extraction functions. The hood is usually positioned close to where emissions occur to gather pollutants upon release. The arm’s flexibility relies heavily upon the joints at play in its movement process. These vital components facilitate reaching remote positions while ensuring stability during operation. Connecting tubes link the extraction arm to a filtration system that processes and eliminates captured pollutants from the air stream.

Advantages of Employing an Extraction Arm

Opting for an extraction arm comes with benefits to consider upfront! Primarily and importantly, it impacts air quality through the elimination of harmful elements present in the environment around us! Breathing air leads to an overall work atmosphere and can help decrease health concerns among staff members significantly. Improving the air quality can also boost productivity, as employees can work effectively without dealing with substance exposure issues.

Selecting the Appropriate Extraction Arm

When deciding on the extraction arm to use for a task at hand in a business setting, it’s important to consider various aspects. Companies need to assess their requirements, such as the kinds of pollutants that may be in the area and how big the workspace is. A grasp of these needs is key in selecting an arm that meets all the features and details. It’s important to evaluate the quality and standing of manufacturers when selecting a trusted supplier. This guarantees that the extraction arm meets industry norms and delivers consistent performance levels. Reviewing feedback from customers and seeking recommendations can also help you make informed choices.

Routine Attention

Keeping an extraction arm maintained is crucial for its longevity and efficiency benefits. It’s essential to conduct inspections to spot any signs of wear or damage for prompt repairs or replacements. Regularly cleaning components like hoods and tubes is necessary to prevent blockages and maintain top-notch performance. It’s crucial to educate staff on how to use and care for extraction arms to reduce the chance of damage and keep the equipment running smoothly. Following the manufacturer’s instructions for maintenance and upkeep is key to preserving the tool’s effectiveness.

In Summary

Ensuring a hygienic workplace is crucial. A typical extraction arm is essential in achieving this objective by eliminating airborne pollutants. This equipment not only enhances air quality but safeguards machinery; its advantages render it indispensable across different sectors. Businesses that are thinking about investing in extraction arms should thoroughly assess their requirements. Select the equipment for their specific needs to guarantee the long-term optimal performance of these tools.Investigating worker safety and productivity first can help companies establish a work environment that’s both healthier and more efficient.