Fiberglass reinforced plastic (FRP), sometimes called Coroplast, is fabricated by fiberglass grating manufacturers. It’s the latest construction material to come along. It’s used everywhere, from large industrial robots to highway patrol vehicles, fire trucks, and buses.

Besides, it’s becoming more popular with home builders due to its strength, lightweight, durability, and ability to be painted colorfully. Numerous homeowners are wondering if they should choose an existing material like iron or steel for their new construction projects or FRP. Here, we take a closer look at what Fiberglass Reinforced Plastic is and how it’s used. Let’s jump right in!

What Is Fiberglass Reinforced Plastic?

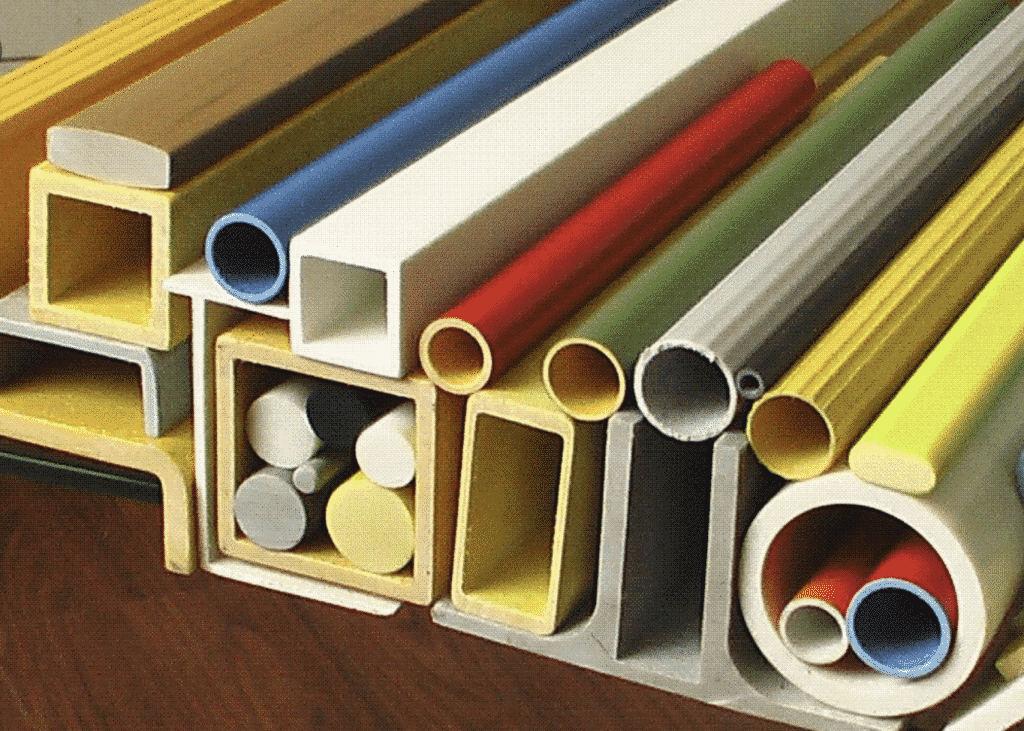

Fiberglass reinforced plastic (FRP) is a lightweight, environmental-friendly alternative to traditional metals, such as aluminum and steel. It consists of hundreds or even thousands of microscopic threads of solidified plastic. The threads are fused to form one solid piece of plastic.

Fiberglass reinforced plastics (FRP) are used in various industries for a variety of reasons. Their popularity stems from the lack of flimsy materials used in commercial structures. Due to this, they are somewhat versatile and can be utilized for nearly anything that needs reinforcement.

FRP is often used to make large equipment pieces, like forklifts or cranes that would otherwise tear under their weight without reinforcement. Businesses can utilize FRP materials to save money on purchasing materials or create structures strong enough to withstand natural disasters. Let’s now look at various uses of fiberglass-reinforced plastics. Read on!

How Is Fiberglass Reinforced Plastic Used?

Some of the applications of Fiberglass reinforced plastics comprise:

Construction Industry

Fiberglass reinforced plastic (FRP) is a material used in the manufacture of lightweight construction products such as:

- Roofing materials

- Cabinet sets

- Fencing

- Pipes

The manufacturing process begins with cutting and molding the desired shape before pouring resin into the clay mold. Then, the molding is covered with heat-resistant polyurethane foam, and the item is packaged ready for shipment.

Aviation Industry

Fiberglass reinforced plastic (FRP) is used to manufacture several commercial aircraft and is becoming popular in the aviation industry. It has an excellent strength-to-weight ratio, making it one of the best materials used in manufacturing aircraft. The most common applications of fiberglass reinforced plastics in the structure of an aircraft include:

- Fuselages

- Undercarriages

- Galleons

- Landing gear

- Guts

Aircraft manufacturers have found that they can reduce cost and weight by using FRP in the aircraft’s structural components. The material is lighter and more durable compared to steel. Also, it can be produced at a lower cost per unit area.

Besides its strength, fiberglass reinforced plastics are thin, making it an attractive choice for smaller aircraft parts. You can easily paint it, making it durable and beautiful.

It makes it an excellent choice for aircraft manufacturers who produce a large number of aircraft. Manufacturers who produce regional aircraft will typically utilize steel and composite materials to minimize cost and maximize economies of scale when manufacturing large airplanes.

Manufacture of Consumer Goods

Fiberglass Reinforced Plastic from fiberglass grating manufacturers is a heat-resistant material found in a variety of consumer goods. It’s because it’s strong and flexible. Flexibility is crucial because it allows products to change size or shape without increasing the cost of the materials.

Fiberglass reinforced plastics is used to make:

- Toys

- Clothing

- Glassware

- Sports gear

- Air conditioners

- Heaters

- Durable packaging vessels

These days, it’s used in everything from construction equipment to kitchen and bathroom cabinets, among other everyday household items. Most fiberglass reinforced plastics products are created using a two-part synthesis process;

- First, powdered fiberglass plastic is squirted into a mold.

- Then, the liquid crystal solution is added to form a solid after the foam has been cured.

Automotive Industry

Fiberglass reinforced plastic is a lightweight material used in the manufacturing of light vehicles and sport-utility vehicles. It has been used for several decades in the manufacture of air filtration equipment, and in recent years, it has garnered increased popularity in producing cars.

It’s a material applied to the sides and the roof of an internal combustion engine of a vehicle for increased strength and durability. This product has been improving the performance and efficiency of these vehicles since its inception in the early 1960s. Since then, it has become a well-known form of reinforced plastic in the emerging market.

This innovative product is used extensively in manufacturing airbags, bumpers, windscreens, and bomb-resistant body structures. Many of today’s top-brand manufacturers are including Fiberglass Reinforced Plastic (FRP) in their vehicle body structures as a way to increase strength and durability without increasing weight.

Protective Gear

Fiberglass reinforced plastic (FRP) is used to fabricate bulletproof vests, body armor, and other specialized protective equipment. This protective equipment is used by law enforcers, firefighters, rescue personnel, and others who need to wear protective gear while performing their duties.

Unlike heavy metal or wood, FRP can be stretched and bent without losing its structural strength. Also, it can be scraped clean without creating debris that can harm an item’s finish. And because it’s inexpensive to produce, numerous items made of Fiberglass Reinforced Plastic (FRP) are pocket-friendly – even for mass-produced military gear.

Marine Industry

FRP is also used for several purposes in the marine industry comprising:

- Marine breakwaters

- Archival vessels

- Pollution control vessels

- Wharf

- Bulkheads

- Aquaculture facilities

- Turn boats

Also, it can be used in the manufacture of marine electronics, such as, onboard video and radar systems, as well as lightweight structures, like doors, walls, and ceilings.

Conclusion

In recent years, fiberglass reinforced plastic has gained popularity due to its many strengths. It can be used to make lightweight, stiff, and strong components for a wide range of products. Fiberglass reinforced plastic is strong because it’s a fabric with blended fibers.

Unlike JBL Fiberglass Reinforced Vinyl (JBL-FRCP), which uses a flame-resistant liquid plastic material, fiber reinforced plastics have no visible flame-retardant additives. The resulting product is more rugged and durable, making it ideal for a variety of applications.