Today’s manufacturing world demands precision, speed, and flexibility. From aerospace to electronics, industries are pushing the limits of design, and even the smallest inaccuracies can lead to big failures. This is where the 5-axis machining center makes the difference. It’s more than just a machine—it is the key to solving the challenges of complex part production. Compared to traditional setups, it delivers higher accuracy, fewer errors, and faster turnaround. As product designs grow increasingly advanced, choosing the right machining technology is no longer optional—it is essential.

The High Stakes of Using Inaccurate Parts

In critical industries like automotive, aerospace, electronics, instruments, and mold manufacturing, precision isn’t just a technical requirement—it’s a safeguard. A single inaccurate part can compromise safety, performance, and competitiveness.

- Automotive: A minor miscalculation in part geometry can compromise engine efficiency or safety systems.

- Aerospace: Aircraft components demand extreme reliability. Even a fraction of a millimeter deviation in a wing flap, for example, can threaten personal safety.

- Electronics: With circuit boards and microcomponents becoming smaller, precise machining is necessary to ensure flawless assembly.

- Instruments: High-performance measuring tools and medical devices rely on components machined with absolute accuracy.

- Molds: Tooling errors in mold production can multiply across thousands of units, leading to costly recalls.

In all these industries, inaccurate parts mean wasted time, higher costs, and severe safety risks. The 5-axis machining center directly addresses these challenges by providing high-precision machining solutions that ensure both quality and consistency.

5-Axis Machining: Definition and Comparison

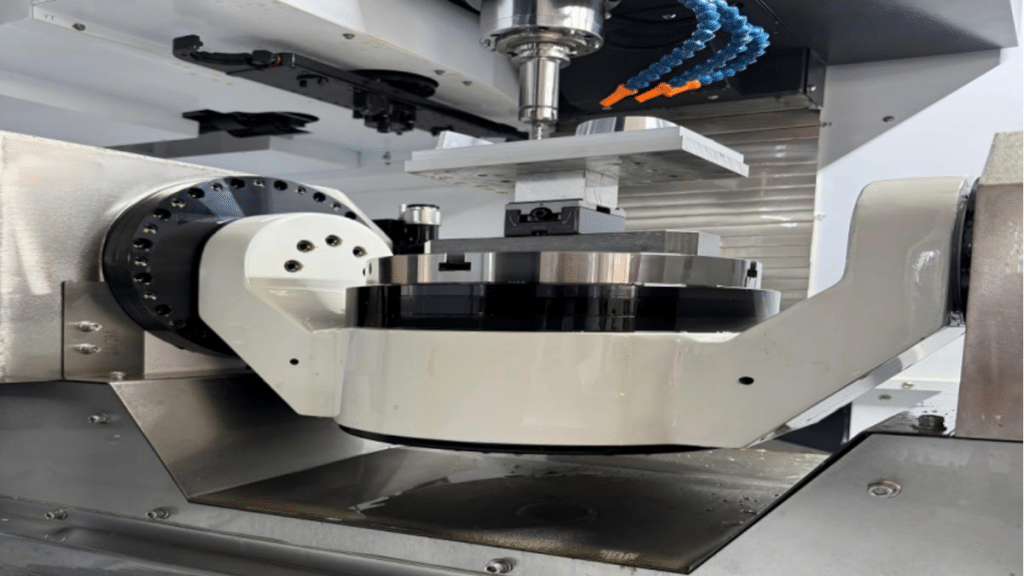

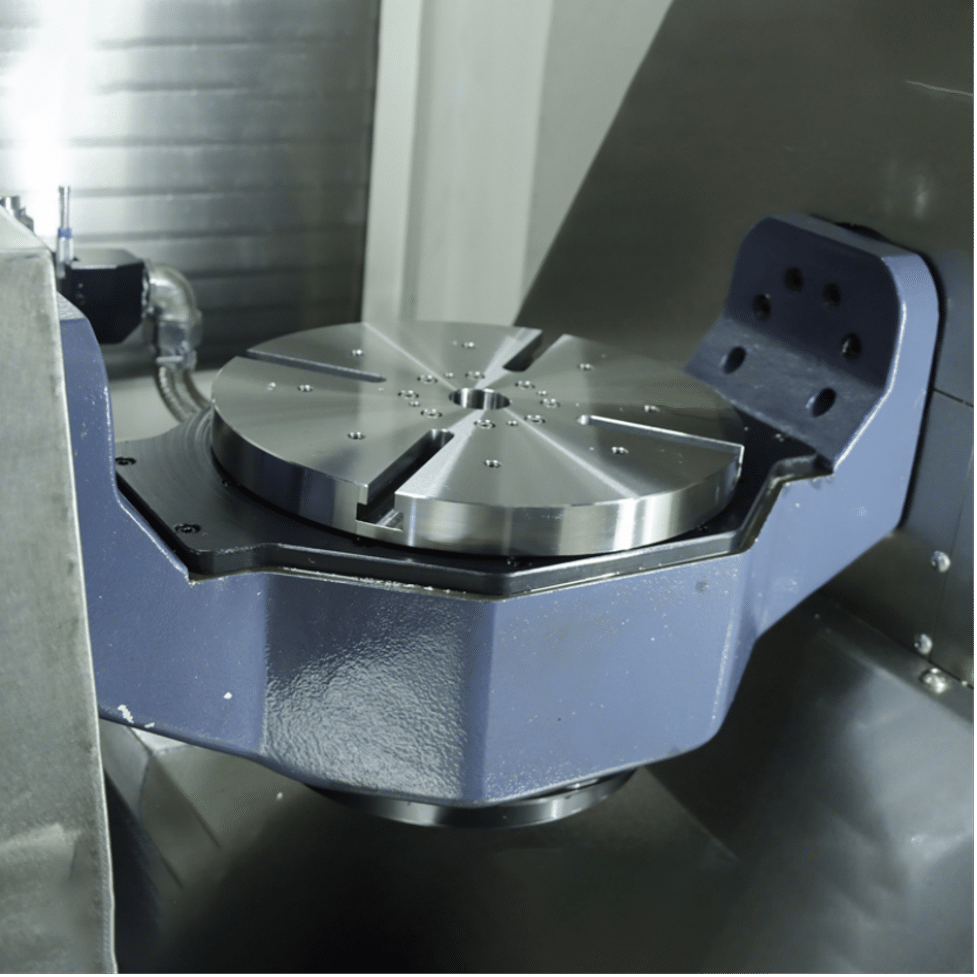

A 5-axis machining center is a CNC machine capable of moving a part or tool along five different axes simultaneously. This allows complex geometries to be machined in one setup, something that 3-axis machines struggle to achieve.

How It Works

Unlike a 3-axis CNC machine, which only moves in the X, Y, and Z directions, a 5-axis machine adds two rotary movements. This flexibility enables cutting on multiple sides of a part without repositioning, dramatically increasing precision and efficiency.

| Feature | 3-Axis CNC | 5-Axis CNC |

| Axes of Movement | 3 (X, Y, Z) | 5 (3 linear + 2 rotary axes) |

| Complexity of Parts | Simple to moderately complex | High (continuous complex surface machining) |

| Setups Required | Multiple setups | Often a single setup |

| Accuracy | Moderate | High precision (no accumulated error) |

| Time Efficiency | Longer production times | Faster, optimized machining cycles |

This table clearly shows why the choice of machine is crucial. When comparing 3-axis vs. 5-axis CNC, the advantage of the latter is clear.

Benefits of 5-Axis Machining for Complex Parts

1. Unmatched Precision and Consistency

With simultaneous multi-axis movement, the 5-axis machining center maintains tolerances within microns. This level of accuracy ensures parts meet exact design requirements, reducing waste and boosting product quality.

2. Reduced Errors and Production Steps

By machining multiple surfaces in one setup, the process reduces the chance of misalignment between steps. Fewer setups also mean shorter lead times and lower labor costs.

3. Supports Mass Production and Prototyping

The flexibility of a 5-axis CNC machine makes it ideal for both high-volume production and rapid prototyping. Whether producing thousands of identical units or a single prototype for testing, the machine adapts easily.

Why Leichman Stands Out

As a leading professional 5-axis CNC machine manufacturer, Leichman is dedicated to delivering advanced solutions for today’s industries. Its machining centers are engineered to achieve the ideal balance of efficiency, durability, and precision. Customers choose Leichman not only for its high-quality machines but also for its expertise in developing customized solutions.

Leichman provides a pathway to innovation and reliability. For businesses that demand accuracy, complexity, and efficiency, Leichman’s 5-axis machining centers are built to perform.