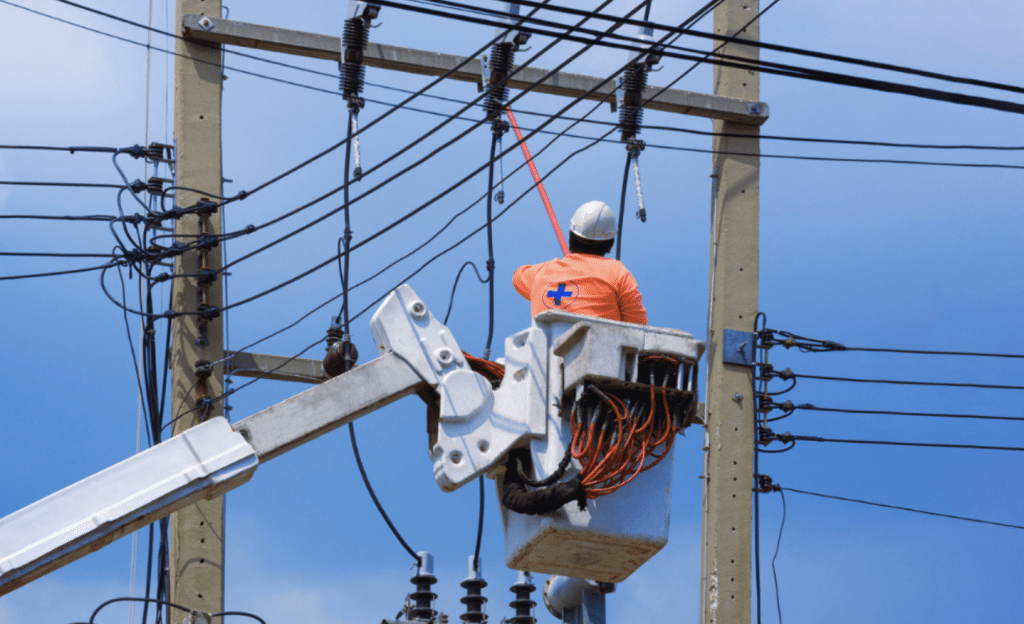

Working in proximity to power lines presents a significant risk of electrocution, a potentially fatal hazard that can occur through direct contact or even arcing from energized lines. Construction workers, utility workers, and anyone working outdoors near power lines must understand the dangers and follow essential safety protocols to prevent electrocution.

Electrocution accidents can result in severe burns, internal injuries, cardiac arrest, or even death. It’s crucial to prioritize safety and take proactive steps to protect yourself and others when working near power lines. In the unfortunate event of an accident, seeking the guidance of a labor injury lawyer can be essential in protecting your rights and obtaining the compensation you deserve.

Maintaining a Safe Distance

The most fundamental safety protocol when working near power lines is maintaining a safe distance. Electricity can arc or “jump” from energized lines, so it’s crucial to stay at least 10 feet away from power lines at all times. This distance should be increased for higher-voltage lines.

If your work requires you to get closer than the safe distance, you must de-energize and ground the lines or use insulated tools and equipment. Never assume that a power line is de-energized; always verify its status with the utility company before beginning work.

Assessing the Worksite for Potential Hazards

Before any work begins, it is critical to conduct a thorough assessment of the worksite. Identifying the location of power lines and understanding the electrical risks associated with the job is the first step in creating a safe work environment. Power lines may not always be easily visible, so workers need to be made aware of any lines that are overhead, buried, or running near equipment.

Employers and supervisors should implement safety measures, such as marking power lines and establishing safe distances. This initial assessment helps workers understand the potential risks and ensures that proper safety procedures are followed to avoid accidental contact with live electrical wires.

Use of Grounding and Insulated Tools

Grounding and using insulated tools effectively reduce the risk of electrocution. Grounding equipment ensures that in the event of accidental contact with a power line, the electrical current is safely redirected away from the worker. Insulated tools, on the other hand, provide an additional layer of protection by preventing electrical conduction.

Employers should ensure that all tools and equipment are properly grounded and insulated as required. Workers must be trained in the correct use of these tools, and regular inspections should be conducted to ensure that the equipment is in good working order. These precautions can significantly reduce the likelihood of electrocution on the job.

Establishing Safe Work Practices

Developing and implementing safe work practices is essential for preventing electrocution accidents. This includes:

- Planning your work carefully: Before starting any work near power lines, assess the risks, develop a safe work plan, and communicate it to all workers involved.

- Using a designated spotter: When working near power lines, have a designated spotter trained to monitor the work area and warn the operator of potential hazards.

- Avoiding overhead power lines: When operating equipment or vehicles near power lines, be aware of their height and maintain a safe distance from overhead lines.

- Never touch downed power lines: If you see a downed power line, assume it is energized and stay away. Report it to the utility company immediately.

Use of Personal Protective Equipment (PPE)

Personal protective equipment (PPE) is essential for reducing the risk of electrocution when working near power lines. Proper PPE includes insulated gloves, boots, and other protective clothing designed to guard against electrical hazards. Workers must be equipped with the right gear for the job, and it is the employer’s responsibility to ensure that PPE is in good condition and used correctly.

In addition to physical protection, PPE reinforces a culture of safety. Workers who wear proper gear are more likely to be conscious of their surroundings and alert to potential dangers. Employers should provide regular training on PPE use and ensure that all workers are familiar with the equipment needed to prevent electrocution.

Emergency Response Preparedness

Even with all the right safety measures in place, accidents can still happen. Being prepared for an emergency is essential for minimizing injury and ensuring a swift response. Workers should be trained in basic first aid and know how to respond in the event of an electrocution. This includes recognizing the signs of electrical shock and knowing how to safely assist a coworker who has been injured.

Employers should have an emergency plan in place that includes immediate medical response procedures and clear communication protocols. Quick action can make a critical difference in the severity of injuries following an electrocution incident, and proper preparedness is key to ensuring the best possible outcome.

Proper Training and Safety Education

Comprehensive training is essential for workers required to work near power lines. All employees must be trained to recognize electrical hazards, understand safe working distances, and know how to use protective equipment. OSHA provides guidelines for electrical safety training, and it is the employer’s responsibility to ensure that these protocols are followed.

Safety education should be ongoing, with regular refresher courses and updated training as new equipment or procedures are introduced. Workers who are well-trained and knowledgeable about electrical hazards are better equipped to avoid dangerous situations and respond appropriately in an emergency.

Ensuring Proper Supervision on High-Risk Jobs

High-risk jobs near power lines require constant supervision to ensure that all safety protocols are followed. Having a qualified supervisor present ensures that workers adhere to guidelines, stay within safe distances, and use proper equipment. Supervisors can also provide immediate intervention if unsafe practices are observed, reducing the risk of accidents.

Proper supervision is not only about overseeing daily operations but also about enforcing accountability. Supervisors should regularly assess the worksite for compliance with safety standards and take corrective action if necessary. Their role is critical in maintaining a culture of safety and preventing electrocution incidents in high-risk work environments.