In the world of product development and design, having access to fast, accurate, and cost-effective prototyping is essential. While several 3D printing technologies exist today, one method stands out when surface quality and fine detail are critical. Stereolithography, also known as SLA, offers a unique combination of precision, smooth finishes, and material flexibility that makes it especially valuable for teams working on functional prototypes and highly detailed parts.

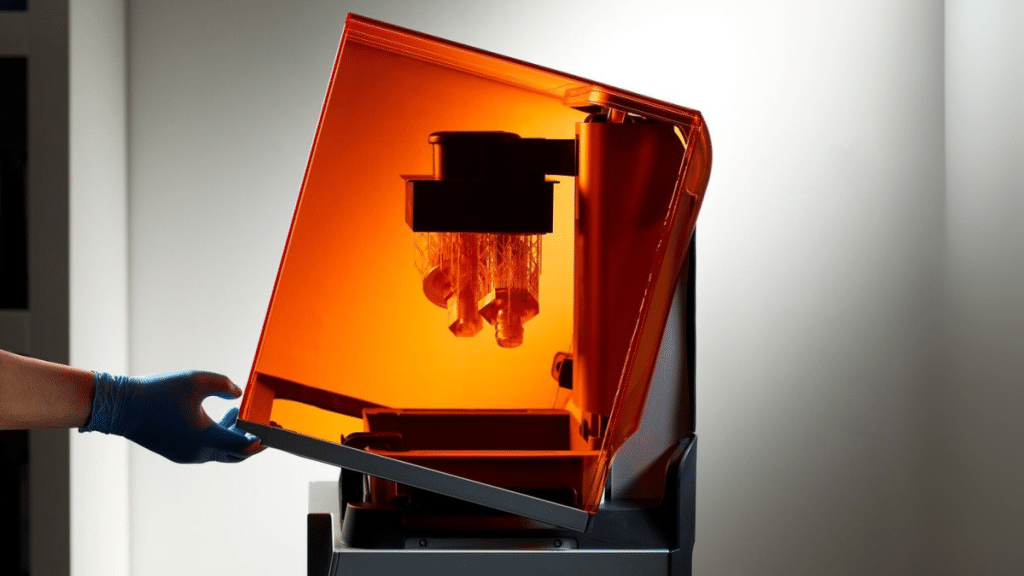

SLA printing works differently than methods that use melted filament or powdered materials. It uses a light-sensitive liquid resin that hardens when exposed to a focused light source. This process allows the printer to create layers with excellent resolution and minimal visible stepping between them. The result is a part that closely resembles an injection-molded object in terms of appearance and finish.

For engineers, designers, and startups trying to move a product from concept to working model, the benefits of SLA printing can be significant. When combined with a reliable custom 3D printing service, it can speed up development timelines and reduce the need for costly tooling.

Precision Where It Counts

One of the key strengths of SLA printing is dimensional accuracy. Because the light-based process cures each layer with precision, it is possible to maintain tight tolerances. This matters when producing prototypes that need to fit with existing parts or when multiple pieces need to assemble correctly.

For example, a company developing a new wearable device might need to test how a housing fits around internal electronics. Even small misalignments could interfere with the final product. SLA parts provide the fidelity needed for these checks without requiring the production of hard tooling or complex jigs.

The consistency of SLA also supports iterative design. When changes are needed, a revised file can be printed with the confidence that results will match previous parts. This predictability makes it easier to test design updates, compare revisions, and move forward with a working concept.

Surface Finish and Aesthetics

For many projects, appearance is more than a secondary concern. Early-stage designs often need to be presented to clients, investors, or internal teams. A prototype that looks clean and professional can help communicate the intent of the final product more effectively.

SLA excels in this area. Because the layers it creates are so fine, the surface is smooth straight from the printer. In some cases, little or no post-processing is needed before painting or handling. This can save time and effort during development, particularly when preparing a model for display or presentation.

In addition, SLA allows for fine detailing that is difficult to achieve with other methods. Textures, thin walls, and engraved features all come through clearly. Designers can add visual complexity to their models without worrying about print limitations.

When used as part of a broader 3D printing area, SLA can fill the role of aesthetic prototyping alongside functional testing. The flexibility to prioritize surface finish or performance makes it a practical choice for teams that value both.

Material Options for Different Needs

Another advantage of SLA printing is the range of resins available. While all SLA machines use light-reactive liquids, not all resins are the same. Manufacturers now offer materials tailored to different use cases, including durable resins for mechanical stress, flexible types for soft-touch applications, and high-temperature variants for testing heat resistance.

This material diversity expands what can be prototyped with SLA. A team testing a mechanical device can print parts that withstand basic stress and impact. A dental lab can create accurate models that hold their shape during handling. A company developing consumer products can test how buttons or connectors feel and perform. Some teams prefer to explore professional SLA 3D printing service providers that specialize in this method to save time and ensure consistent results.

Access to these options makes SLA a flexible tool, even beyond cosmetic modeling. It allows teams to simulate the look and feel of end-use parts more closely, which in turn improves decision-making throughout the development process.

Prototyping Without Commitment to Tooling

One of the traditional barriers in hardware development has been the need for tooling. Creating molds, dies, or machining programs takes time and money. For small teams or early-stage products, this step can feel risky, especially if the design is still in flux.

SLA allows companies to delay or avoid that investment altogether. By printing small batches of parts directly from CAD files, they can test ideas, validate features, and gather feedback before any tooling is made. This not only saves money but also supports a more flexible workflow.

If a test shows that a feature should be adjusted or removed, there is no sunk cost. A new file can be printed in a matter of hours. For companies that want to stay agile in their product development, this freedom is especially useful.

This is one of the reasons many turn to a trusted custom 3D printing service that offers SLA. It allows them to request small runs or individual parts without having to invest in machines or materials themselves.

Where SLA Fits Best

Although SLA printing has many strengths, it is not always the right tool for every job. It is best suited to parts that require high detail, smooth surfaces, and reliable accuracy. For very large parts or those that need to be printed in bulk, other methods might be more cost-effective.

Still, for a wide range of use cases, from early concept models to pre-production testing, SLA provides a balance of speed and quality that supports smarter development. It reduces the time between idea and prototype, lowers the cost of changes, and gives teams more control over their designs.

As the demand for customized products and efficient development cycles grows, processes like SLA will likely become even more valuable. They offer a bridge between digital design and real-world testing, helping teams move from plan to product without unnecessary delays.