Marijuana, also known as cannabis, is a plant that has been used for its medicinal and recreational properties for centuries. As more states legalize its use, the cannabis industry is rapidly growing. This growth has led to an increase in cannabis product manufacturing, with product makers producing a variety of cannabis products. However, to produce high-quality cannabis products, it’s crucial to understand the cultivation, processing, and packaging of marijuana.

Cultivation of Marijuana

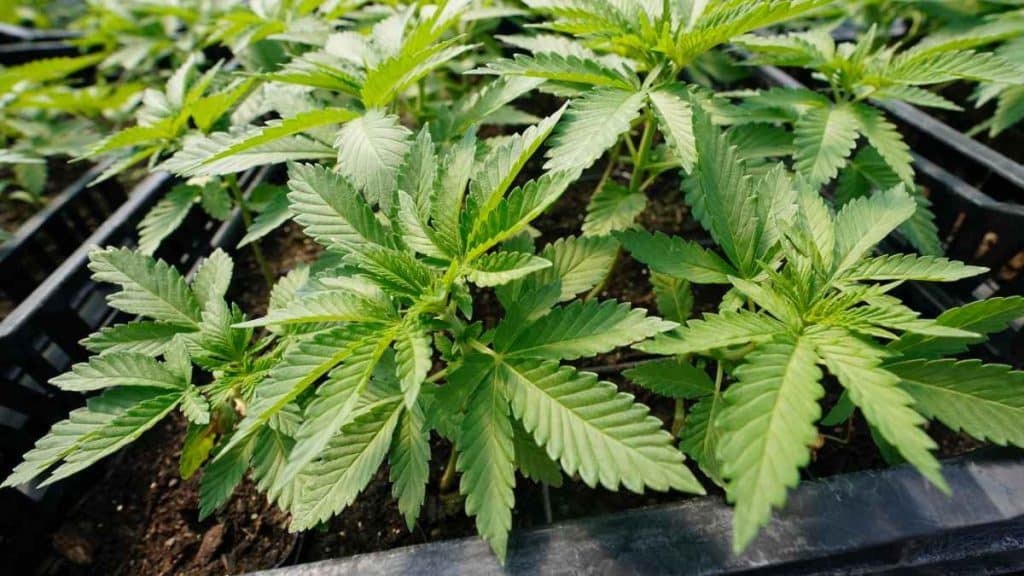

The first step in producing high-quality cannabis products is the cultivation of marijuana. There are two main methods of cultivation: indoor and outdoor.

Indoor Cultivation

Indoor cultivation involves growing marijuana in a controlled environment, usually inside a building. This method of cultivation allows for complete control over the growing environment, including lighting and temperature control.

- Growing Environment – The first step is creating the growing environment. The grow room should be clean, secure, and well-ventilated. Growers also need to choose the right growing medium and nutrients for their plants.

- Planting and Growth Process – Once the grow room is set up, the planting process begins. Growers start with seeds or clones, which are small cuttings taken from mature plants. The plants are then placed in pots or hydroponic systems, where they’ll grow until they reach maturity.

- Lighting and Temperature Control – Lighting and temperature control are crucial in indoor cultivation. They need to provide the right amount of light for their plants and maintain a stable temperature. They typically use high-intensity discharge (HID) lamps, which provide the optimal spectrum of light for plant growth.

Outdoor Cultivation

The process of outdoor cultivation entails the growth of marijuana in a natural environment, with no artificial intervention. This technique relies solely on the natural elements of the environment, such as sunlight and the quality of the soil.

- Growing Environment – The outdoor growing environment is determined by the location and climate. Growers need to choose a location with the right amount of sunlight and good soil quality. They also need to consider environmental factors such as wind, rain, and pests.

- Planting and Growth Process – This process is similar to indoor cultivation, but the plants are usually started from seeds, rather than clones. Once the plants are established, they require minimal maintenance as they grow in the natural environment.

- Natural Environmental Factors – Natural environments can have a significant impact on the quality of the plants. Growers need to monitor environmental factors, such as rainfall and temperature, to ensure optimal growth.

Processing of Marijuana

After the marijuana plants are grown, they need to be processed before they can be used in cannabis products. The processing of marijuana involves several steps, including harvesting, drying and curing, and trimming.

Harvesting

Harvesting is the procedure of cutting down mature plants. Growers need to determine the right time to harvest to ensure the best possible yield and quality. They use a variety of techniques to harvest the plants, including cutting them down by hand and using mechanical harvesters.

Drying and Curing

Once the plants have been harvested, the subsequent step is to dry and cure them. Drying entails extracting the moisture from the plant, while curing requires the dried plants to be kept in a controlled environment, enhancing the flavor and potency of the plant. The drying and curing process is a time-consuming one, lasting for several weeks.

Trimming

The buds must undergo trimming, which includes carefully removing the leaves from the buds, leaving behind the most potent part of the plant. Trimming is a crucial step that affects the quality and appearance of the final product. Once the buds have been trimmed, they are considered to be of a higher quality and are ready to be used in various cannabis products.

Packaging of Marijuana

Cannabis packaging is essential for protecting the quality of the products and ensuring that they meet legal requirements.

- Importance of Packaging – Packaging serves several purposes, including protecting the product from damage, preventing tampering, and complying with legal requirements.

- Packaging Materials – There are several types of packaging materials that cannabis product makers can choose from. Glass jars are a popular option as they’re airtight and preserve the product’s flavor and potency. Plastic bags are also commonly used, but they’re less effective at preserving the product’s quality. Other packaging materials, such as metal tins and cardboard boxes, are becoming more popular as the cannabis industry continues to grow.

- Packaging Regulations – Packaging regulations for cannabis products vary depending on state and federal laws. In general, packaging must be child-resistant, opaque, and have warning labels that include the product’s potency and any potential health risks. Failure to comply with packaging regulations can result in fines or legal action.

Cannabis manufacturing is a complex process that involves cultivation, processing, and packaging. Understanding each step of the process is crucial for producing high-quality cannabis products that meet legal requirements and consumer expectations.

As the cannabis industry continues to grow, it’s essential for cannabis product makers to stay informed of new developments in cannabis cultivation, processing, and packaging. By doing so, they can continue to provide their customers with safe and effective cannabis products.