The selection of the correct equipment partner can either break or make your business operations. A correct choice ensures that your processes are smooth, cost-effective, and long-lasting. There are so many options available in the market that it is difficult to understand what to look for. A good industrial equipment supplier should provide good-quality equipment and excellent after-sales service and maintenance. They must know your business objectives and strive to help you achieve those effectively.

It is about how a company is perceived to do business in your industry and, again, their track record in your industry. Find yourself a partner that keeps up-to-date with the latest technology to meet your ever-changing requirements, one that is flexible. Another key aspect is to consider transparency in communication. An excellent partner will work out everything with you to bring complete seamlessness in your processes and operations. This will guide you through the selection with complete confidence. Let’s dive into the steps to find a partner who truly supports your business needs!

Understanding Your Business Needs

First, understand your specific business operation needs. Evaluate what type of equipment your business needs to operate effectively. For instance, if your industry requires high-demand industry tools, identify what features and capabilities you need. Also, it is important to look ahead: will your needs increase or change in the next few years? Identifying these will ensure that you select a partner who can meet your demands, both at the moment and in the future. Knowing the size of your operation will also help you to gauge the volume and type of equipment that you will need. Smaller businesses may need flexibility in order sizes, while larger companies may require suppliers with substantial inventory.

A thorough needs assessment should also include your operational goals. Consider whether your business prioritizes speed, precision, or cost-efficiency, as this will affect the type of industrial tooling and industrial equipment supply you require. Businesses in high-demand industries should also account for peak seasons or increased workloads. A partner who understands these fluctuations will be better equipped to deliver reliable service. Ultimately, clarity on your requirements forms the foundation for making a well-informed choice.

Researching Potential Equipment Partners

Not all equipment partners are created equal, so research will be important. Seek out suppliers with a proven track record in the area of industrial equipment supply. Check their track record to see if they have successfully provided for companies within your business segment. Check reviews and testimonials about the experiences of past clients. A good partner should have expertise with high-demand industry tools and a proven ability to deliver quality products and services.

Take the time to assess their market presence and reliability. A well-established partner is often better equipped to handle complex supply demands and ensure timely deliveries. Speak to their previous clients or request references to validate their claims. Pay attention to their experience in your specific industry. For instance, a partner with expertise in manufacturing equipment may not always be the best fit for a construction-focused business.

Also, consider their logistics. Those with developed industrial tooling and supply chains are more likely to handle urgent orders and maintain consistent inventory. Also, ensure the supplier is financially stable since this is reflected in their ability to continue operations during economic downturns. These factors help to build trust and confidence in their ability to support your business long-term.

Assessing Product Quality and Range

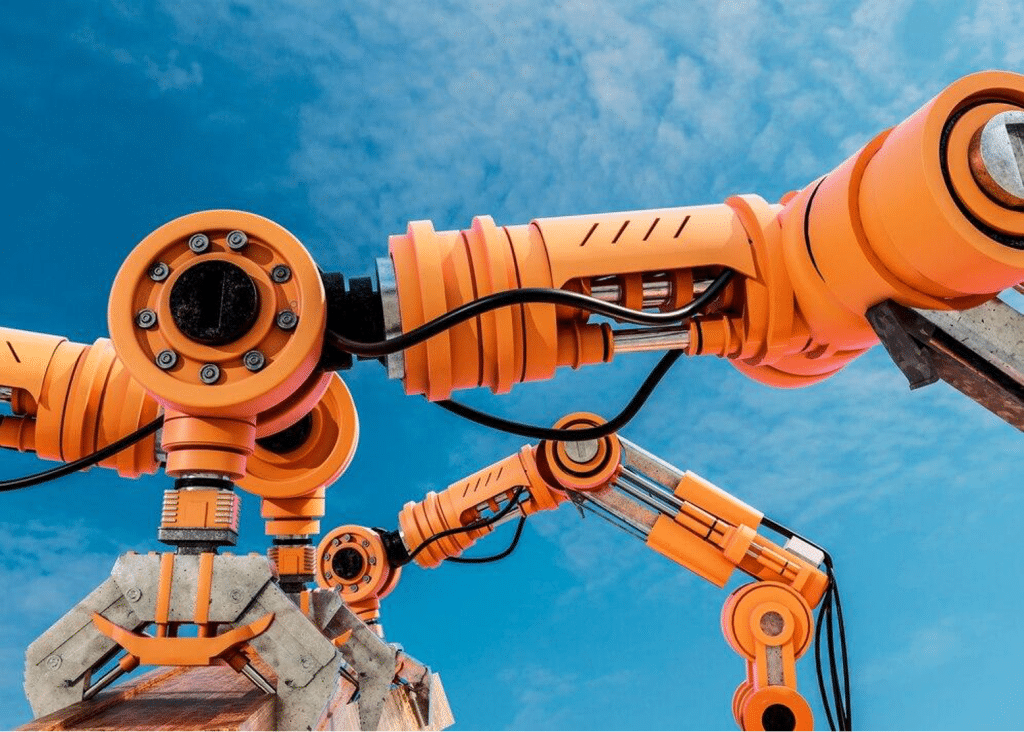

The quality and variety of equipment a supplier offers is a major factor. For that matter, ensure your partner provides durable and reliable industrial tooling and supplies to meet your needs. A wide product range gives you flexibility in the choice of the best tools for your operations. Additionally, consider whether they stay up-to-date with the latest technological advancements. Such partners might offer cutting-edge equipment for a competitive advantage in conducting your business.

Assess the quality of materials used in the products, as this directly impacts durability and performance. For high-demand industry tools, precision and consistency are key, so ensure the partner maintains strict quality standards. Enquire about the testing and certification processes their equipment undergo to verify compliance with industry regulations.

It is also very important to check the range of products they have on offer. A supplier with a wide range allows you to consolidate your sourcing needs, saving you time and effort. You should look for partners that stock both commonly used tools and specialized equipment for niche applications. The availability of spare parts and accessories is another crucial factor that will influence your decision. A well-stocked supplier ensures your equipment stays operational even during unexpected breakdowns.

Assessing Support and Maintenance Services

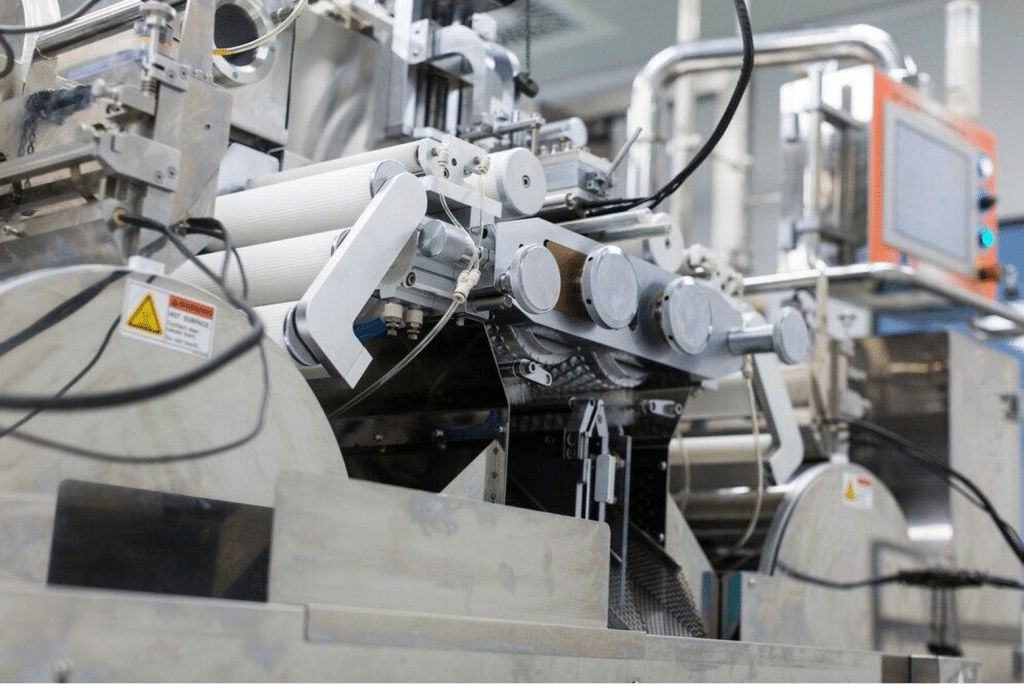

Support and maintenance services minimize downtime and ensure smooth operation. A good partner would provide support on a constant basis, including regular checkups and training on high-demand industry tools. Assess their response time for replacements or repairs since this could disrupt workflow. A partner committed to excellent service will make your business’s success their top priority.

Confirm first if they are available for technical support. Do they have chat lines or lines that one can use in case of emergencies, or even outside standard working hours? A responsive partner minimizes your business’ downtime. Find out whether they will be providing your team with any training to handle the industrial tooling and supply properly; proper handling can extend equipment life and enhance productivity.

Also, check their warranty policies. A full warranty represents confidence on the part of the supplier in their products. The value is further added by maintenance packages, such as routine inspections or discounted repairs. And don’t forget to ask about their inventory of replacement parts and their ability for on-site servicing. A partner who invests in your operational continuity will always stand out.

Checking Flexibility and Communication

Flexibility and transparency rank high among the characteristics that define a very good partner in equipment. Businesses evolve, and your needs could change with time. Select a partner that can flex toward your needs. Just as important is clear, timely communication to keep you up to date on things like delivery schedules, product updates, or service agreements.

Adaptability is particularly crucial in high-growth industries. Your equipment partner should scale their offerings to match your evolving operations. Whether it is adjusting order quantities or introducing new technologies, flexibility ensures your needs are met without delays.

Good communication also helps to develop trust and minimize misunderstandings. Ensure that your chosen partner gives you timely information regarding the level of inventory, tracking of shipment, and routine maintenance. Open channels of communication enable you to head off potential problems before they become major concerns. A collaborative partner will make sure that their services fit with your needs.

Comparing Costs and Value

While the cost is a major factor, it should never outshine quality. Compare the prices from different suppliers and make sure that the supply for industrial equipment you pick offers great value. Warranty, service packages, and training options should be sought to ensure your investment. Avoid taking shortcuts with cheaper options that compromise on durability or performance.

Request detailed quotations to ascertain what each supplier includes in their quote. Is maintenance and support included, or is it an additional service? Assess the life-cycle cost of ownership, considering maintenance, repairs, and operating efficiency over the asset’s life.

Consider long-term savings over short-term costs. High-quality equipment may have a higher upfront price but often requires fewer repairs and lasts longer. If a supplier offers financing options or flexible payment terms, premium equipment can be made more accessible. Prioritizing value over cost ensures your business stays competitive and productive.

Choosing the right equipment partner requires careful evaluation of your needs, research, and a focus on quality and service. A good partner will not only supply top-quality industrial tooling and supplies but also help grow your business with flexibility and knowledge. They will adapt to your needs, communicate effectively, and add value to the services they provide to further enhance your operations. By following these steps, you can find a partner who ensures your operations run efficiently and effectively, setting your business up for long-term success.